Now that's what I'm talking about !!! Thank You !!! Excellent !!!

so much easier get details about each part before one of us comments. If left to us

then sometimes we are going to take the easy path and just guess.

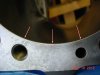

I think we getting a handle on the SCR/DCR of your motor, but you have a

Quench Distance(QD) = .064 inches. That needs to be reduced by head gasket

thickness or milling the block. Have your block checked for warping of the deck

surface, you might have to deck it enough to flatten it out or maybe you want

to take more for your QD. To make your measurements now, you will want to

assemble the rotating assemble enough to check deck height with your new parts.

But I don't see your pistons, rods or crankshaft.

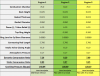

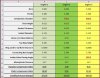

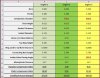

Let's pretend for a moment that you are going to deck the block by .010 inches thus

leaving the deck height at .015 now. Now change to gasket thickness to .025 inches

and you have your QD of .040 inches ..... right were you want it!!! Now what does

this do to your CRs???

Engine 1 is pushing it on the DCR with 91 octane, so lets try the bigger chamber head

of 70cc for engine 2, well that's abit too low for the DCR. Lets try for engine 3 going

back to the 64cc heads and retarding the camshaft 4°. Sweet right in there at 8.05 DCR.

The above is just an example, so figure out what pistons you might want, some have 5cc

and some have 7.5 cc for the valve reliefs.

But are you not going to bore the engine? Better change number and run the calcs again!

What octane do you plan on using???

NOTE: The changing number for each subsequent engine is big and RED.

.

so much easier get details about each part before one of us comments. If left to us

then sometimes we are going to take the easy path and just guess.

I think we getting a handle on the SCR/DCR of your motor, but you have a

Quench Distance(QD) = .064 inches. That needs to be reduced by head gasket

thickness or milling the block. Have your block checked for warping of the deck

surface, you might have to deck it enough to flatten it out or maybe you want

to take more for your QD. To make your measurements now, you will want to

assemble the rotating assemble enough to check deck height with your new parts.

But I don't see your pistons, rods or crankshaft.

Let's pretend for a moment that you are going to deck the block by .010 inches thus

leaving the deck height at .015 now. Now change to gasket thickness to .025 inches

and you have your QD of .040 inches ..... right were you want it!!! Now what does

this do to your CRs???

Engine 1 is pushing it on the DCR with 91 octane, so lets try the bigger chamber head

of 70cc for engine 2, well that's abit too low for the DCR. Lets try for engine 3 going

back to the 64cc heads and retarding the camshaft 4°. Sweet right in there at 8.05 DCR.

The above is just an example, so figure out what pistons you might want, some have 5cc

and some have 7.5 cc for the valve reliefs.

But are you not going to bore the engine? Better change number and run the calcs again!

What octane do you plan on using???

NOTE: The changing number for each subsequent engine is big and RED.

.

Last edited: