You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"The 14 Car" Performance therapy project

- Thread starter NOT A TA

- Start date

8

87vette81big

Guest

I have the shorter 3-piece Spoiler on my 70 TA 70 Bird Man. Still in good shape.

I had forgotten there was a Taller version used on later Trans Ams & Formula Models.

3-Piece rear spoiler was only stock on Trans Am.

Optional on Formula Model if checked off on orfer sheet when new.

Also the 1978-79 Pontiac Firebird Redbird, Blue Bird, & Yellow Bird Cars had the 3-piece spoiler . I recall seeing all with them. Been 25-30 years now since I seen one of Those Rebirds & Blue Birds.

I had forgotten there was a Taller version used on later Trans Ams & Formula Models.

3-Piece rear spoiler was only stock on Trans Am.

Optional on Formula Model if checked off on orfer sheet when new.

Also the 1978-79 Pontiac Firebird Redbird, Blue Bird, & Yellow Bird Cars had the 3-piece spoiler . I recall seeing all with them. Been 25-30 years now since I seen one of Those Rebirds & Blue Birds.

NOT A TA

reliable source of info

87 vette, The rear spoiler center sections were all the same height 70-81. The tall vs. short look of the spoilers for the 70-78 was due to the end caps. Early 2nd gens (70-73?) got the short version and 74?-78 got the longer one, then 79-81 got their own style. The "custom extra tall" one I made out of a 76 so it had the longer end caps. I debated whether to cut them off to the length of the early style but because I had raised the whole spoiler height 1 1/4" I thought it would look "funny" and top heavy so I made them like the 74 - 78's. In the pic below the top of the black line on the tape next to the end cap would be the bottom of the early short end cap. My stock height spoiler is the short end cap style correct for the year like you have on your car.

NOT A TA

reliable source of info

Dorian,

I knew someone would think about cutting those by hand. I learned from old school tradesmen when I was very young. I wasn't allowed to use power tools (that could be set up to cut things precisely) until I could accurately perform the same tasks by hand. Came in handy because I didn't have anything that could hold a cylinder that large in diameter and cut it square. I thought about running over to the machine shop and milling it down but figured I'd just do it by hand in my home shop.

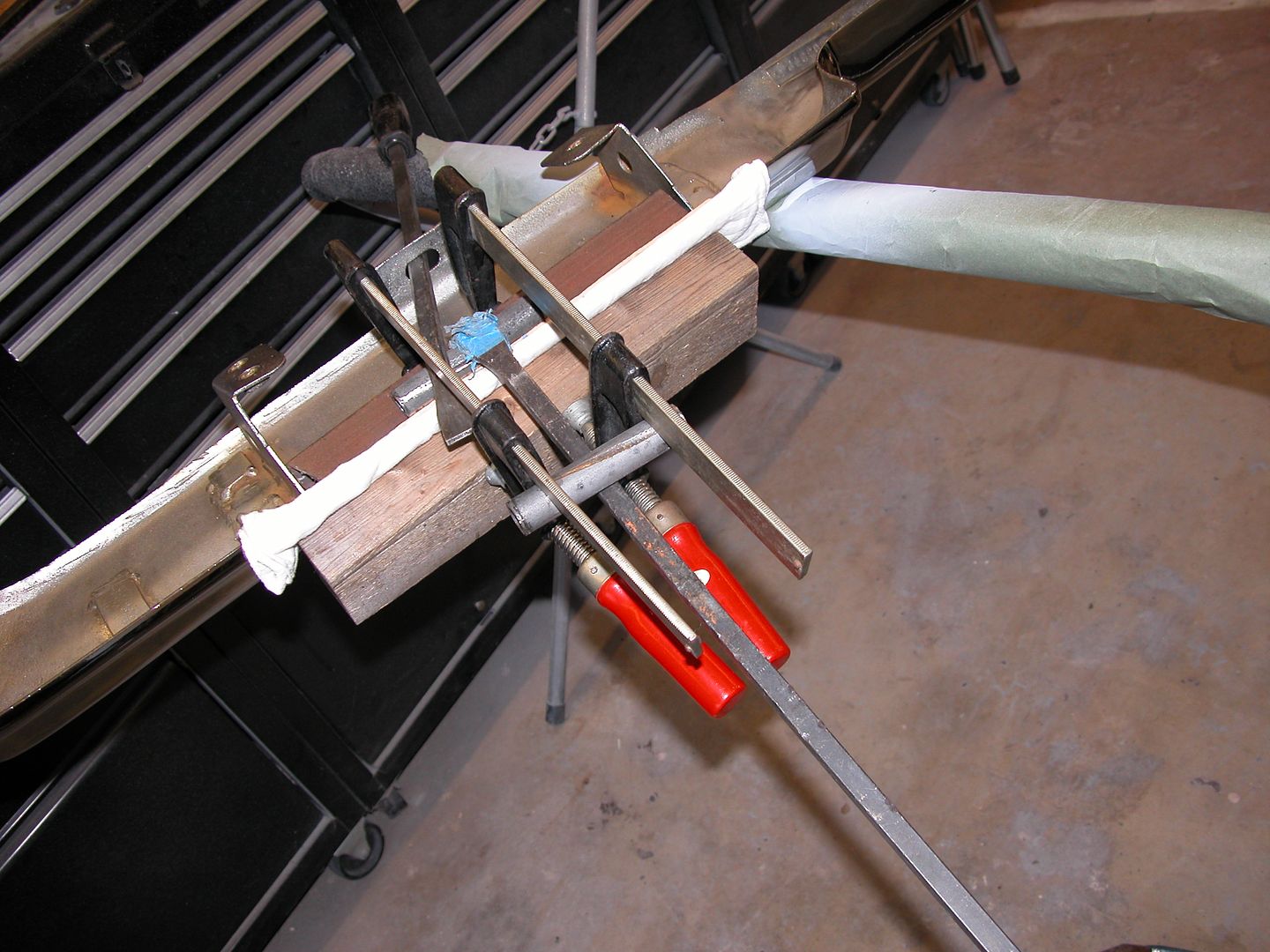

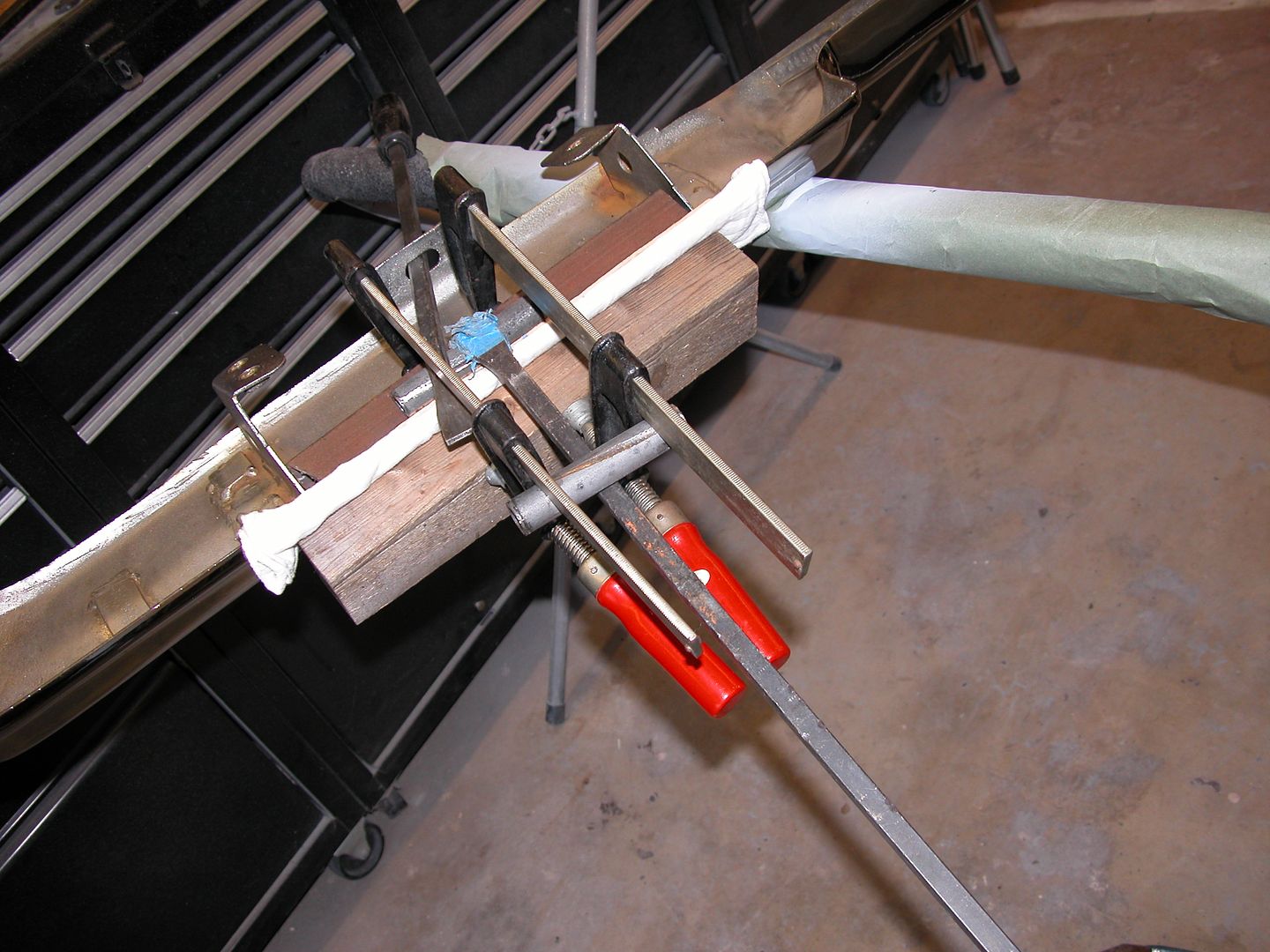

In case you wondered how to complete the cut where the vice is clamping the body mount in the pic above without bending the part being cut off......

I knew someone would think about cutting those by hand. I learned from old school tradesmen when I was very young. I wasn't allowed to use power tools (that could be set up to cut things precisely) until I could accurately perform the same tasks by hand. Came in handy because I didn't have anything that could hold a cylinder that large in diameter and cut it square. I thought about running over to the machine shop and milling it down but figured I'd just do it by hand in my home shop.

In case you wondered how to complete the cut where the vice is clamping the body mount in the pic above without bending the part being cut off......

NOT A TA

reliable source of info

Rick, Thanks!

Phil, Thanks for the props on the pics and I'll tell the elves they're doing a pretty good job. (Don't want them to get a big head or ask for raises ya know). I've had them out in the shop tweaking the rear bumper to straighten it to my standards and figuring out the duct system for the front brake cooling tonight. They work well together but sometimes they scare me a little when I see things they're trying. Here's a couple spy shots I got when I snuck up on them earlier. There were about a half dozen of them sitting on the pry bars and jumping up and down on the bumper and clamps but I think they finally got it where I want it. When they let me do the finish work (and take credit) I'll post about what they were up to.

Phil, Thanks for the props on the pics and I'll tell the elves they're doing a pretty good job. (Don't want them to get a big head or ask for raises ya know). I've had them out in the shop tweaking the rear bumper to straighten it to my standards and figuring out the duct system for the front brake cooling tonight. They work well together but sometimes they scare me a little when I see things they're trying. Here's a couple spy shots I got when I snuck up on them earlier. There were about a half dozen of them sitting on the pry bars and jumping up and down on the bumper and clamps but I think they finally got it where I want it. When they let me do the finish work (and take credit) I'll post about what they were up to.

I knew someone would think about cutting those by hand. I learned from old school tradesmen when I was very young. I wasn't allowed to use power tools (that could be set up to cut things precisely) until I could accurately perform the same tasks by hand. Came in handy because I didn't have anything that could hold a cylinder that large in diameter and cut it square. I thought about running over to the machine shop and milling it down but figured I'd just do it by hand in my home shop.

That's just:

NOT A TA said said:I knew someone would think about cutting those by hand. I learned from old school tradesmen when I was very young. I wasn't allowed to use power tools (that could be set up to cut things precisely) until I could accurately perform the same tasks by hand. Came in handy because I didn't have anything that could hold a cylinder that large in diameter and cut it square. I thought about running over to the machine shop and milling it down but figured I'd just do it by hand in my home shop.

you certainly have far more patience, and skill with a hacksaw than I do, about the time I built my shop (15 years or so ago, when I was working full time before I got hurt on the job, busted ankle ,knee and damaged back) I started checking on the price of a fairly cheap mill and saving but I noticed prices kept going up fairly rapidly so I eventually took what I saved and used a credit card to cover the balance (still not sure that was smart) but the cost of a similar mill had doubled in the last 10- years`

http://garage.grumpysperformance.com/index.php?threads/milling-machine-related.4231/#post-39800

Last edited:

8

87vette81big

Guest

87 vette, The rear spoiler center sections were all the same height 70-81. The tall vs. short look of the spoilers for the 70-78 was due to the end caps. Early 2nd gens (70-73?) got the short version and 74?-78 got the longer one, then 79-81 got their own style. The "custom extra tall" one I made out of a 76 so it had the longer end caps. I debated whether to cut them off to the length of the early style but because I had raised the whole spoiler height 1 1/4" I thought it would look "funny" and top heavy so I made them like the 74 - 78's. In the pic below the top of the black line on the tape next to the end cap would be the bottom of the early short end cap. My stock height spoiler is the short end cap style correct for the year like you have on your car.

I see it '70 Bird Man.87 vette, The rear spoiler center sections were all the same height 70-81. The tall vs. short look of the spoilers for the 70-78 was due to the end caps. Early 2nd gens (70-73?) got the short version and 74?-78 got the longer one, then 79-81 got their own style. The "custom extra tall" one I made out of a 76 so it had the longer end caps. I debated whether to cut them off to the length of the early style but because I had raised the whole spoiler height 1 1/4" I thought it would look "funny" and top heavy so I made them like the 74 - 78's. In the pic below the top of the black line on the tape next to the end cap would be the bottom of the early short end cap. My stock height spoiler is the short end cap style correct for the year like you have on your car.

I have the short style end caps on 1970 TA.

You an I have been around long enough when Pontiac Trans Am's & Firebirds were worthless almost.

Just Die hards like us scooped them up.

Stashed away goodie parts too.

I took shit crap from every single Chevy guy around but one single old timer like Grumpy.

My late bud Bill.

He loved Poncho Pontiacs too. Corvette guy also.

Funny thing is now Pontiacs are worth more than most any Chevy out there.

Faster than most too bone stock or lightly - heavily modified.

NOT A TA

reliable source of info

You an I have been around long enough when Pontiac Trans Am's & Firebirds were worthless almost.

Just Die hards like us scooped them up.

Stashed away goodie parts too.

I took shit crap from every single Chevy guy around but one single old timer like Grumpy.

My late bud Bill.

He loved Poncho Pontiacs too. Corvette guy also.

I bought this Firebird for $190.00 with 42, 000 miles on it back when no one wanted them. I also have a an older friend Richie who is a diehard Pontiac guy. I think he was more excited about this car getting in Hot Rod and Popular Hot Rodding than I was, like a proud poppa. He'd let me store it at his garage, use the lift, and give me a hand when I first got it 25 years ago. He'd worked as a mechanic at a Pontiac dealership in the late 60's early 70's and knew the muscle era cars well.

NOT A TA

reliable source of info

you certainly have far more patience, and skill with a hacksaw than I do, about the time I built my shop (15 years or so ago, when I was working full time before I got hurt on the job, busted ankle ,knee and damaged back) I started checking on the price of a fairly cheap mill and saving but I noticed prices kept going up fairly rapidly so I eventually took what I saved and used a credit card to cover the balance (still not sure that was smart) but the cost of a similar mill had doubled in the last 10- years`

http://garage.grumpysperformance.com/index.php?threads/milling-machine-related.4231/#post-39800

I keep my eyes and ears open hoping for a deal on used machines and tools. Got a bead roller yesterday, a shrinker and stretcher a couple weeks ago and other various metalworking welding tools from a bud cleaning out his shop. He figures he doesn't use them hardly ever and if he does need them he could borrow them. It would take less time for him to drive around the block from his shop (a huge mess) to mine (organized, everything has a place) than find the stuff in his own shop ahahaha.

Last edited by a moderator:

8

87vette81big

Guest

She is going to be Killer Nice & Fast your 1970 Firebird , '70 Birdman.

I paid $3,500 for my '70 T/A.

No regrets.

I paid $3,500 for my '70 T/A.

No regrets.

NOT A TA

reliable source of info

She is going to be Killer Nice & Fast your 1970 Firebird , '70 Birdman.

I paid $3,500 for my '70 T/A.

No regrets.

Your car's probably worth 10 times that now! Today a correct intake, carb, air cleaner base, and shaker for that car is close to $3500.00!

Phil, the elves were out in the shop this evening aligning rear tail lights, bezels, tail panel, and started bumper alignment. I've gotta work in a body shop tomorrow so they'll just goof off all day but when I get home I'll crack the whip and see if I can get them to finish up bumper alignment.

8

87vette81big

Guest

Much more $ because Its all 1970 Ram Air 4 '70 Bird Man.

Last time I had seen a 1970 Ram Air 4 Carb Sell it went for $3,800 on ebay open auction that started off at $.99 cents. That was 2009. Mopar Bob watched with me. Over 300 bids made in last 1 hour of auction.

Both said Holy Fuck to each other.

1970 Ram Air 4 aluminium intake and crossover $2K.

Real and very last Factory 1970-1/2 Trans Am Ram Air 4 shaker hoodscoop.

Dual snorkle. Bought from another 70TA Ram Air 4 owner on East Coast.

$5K easy.

1974 SD455 Auto carb 800 cfm I have used much of the time. $4-5k.

Last time I had seen a 1970 Ram Air 4 Carb Sell it went for $3,800 on ebay open auction that started off at $.99 cents. That was 2009. Mopar Bob watched with me. Over 300 bids made in last 1 hour of auction.

Both said Holy Fuck to each other.

1970 Ram Air 4 aluminium intake and crossover $2K.

Real and very last Factory 1970-1/2 Trans Am Ram Air 4 shaker hoodscoop.

Dual snorkle. Bought from another 70TA Ram Air 4 owner on East Coast.

$5K easy.

1974 SD455 Auto carb 800 cfm I have used much of the time. $4-5k.

NOT A TA

reliable source of info

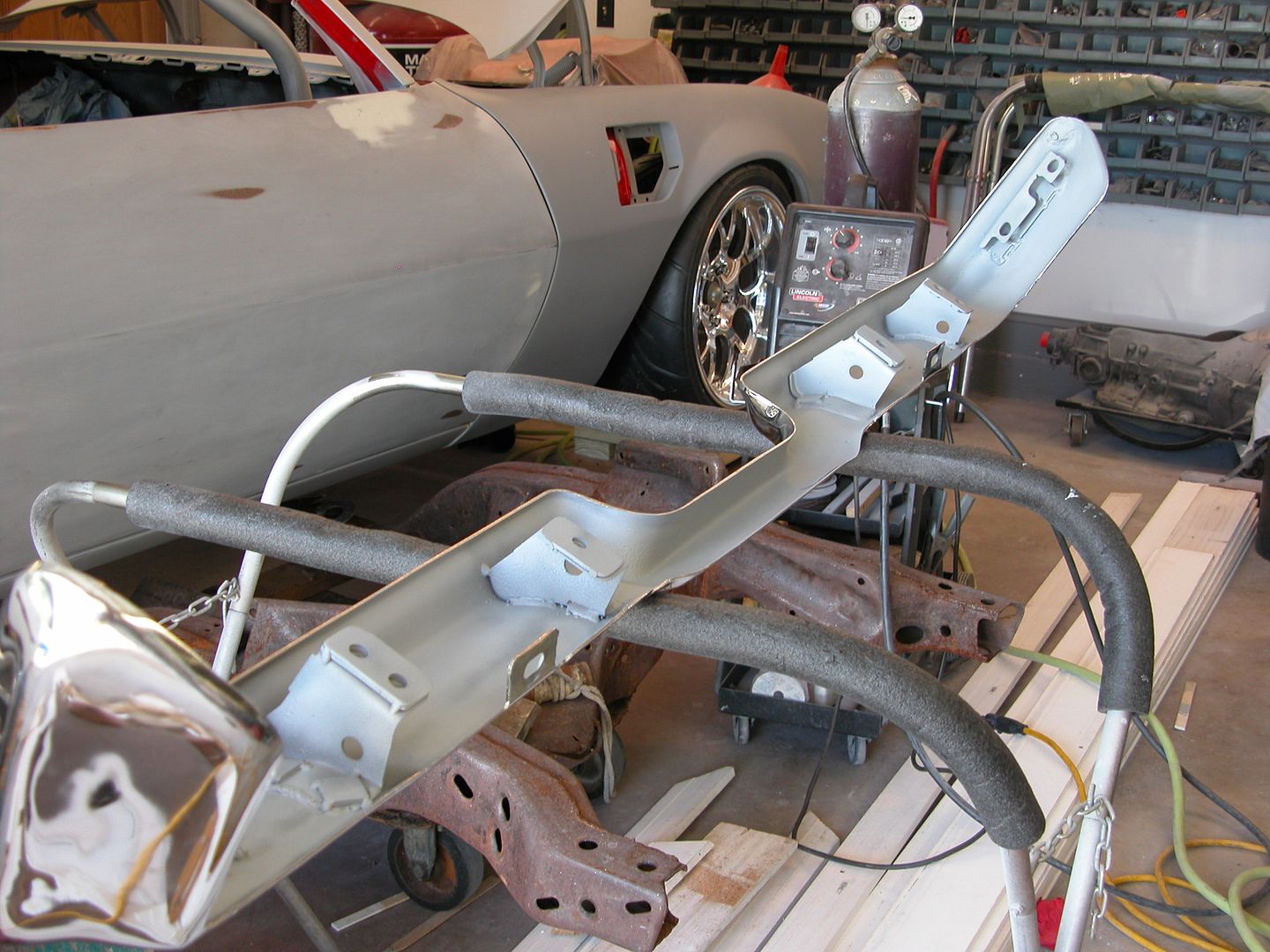

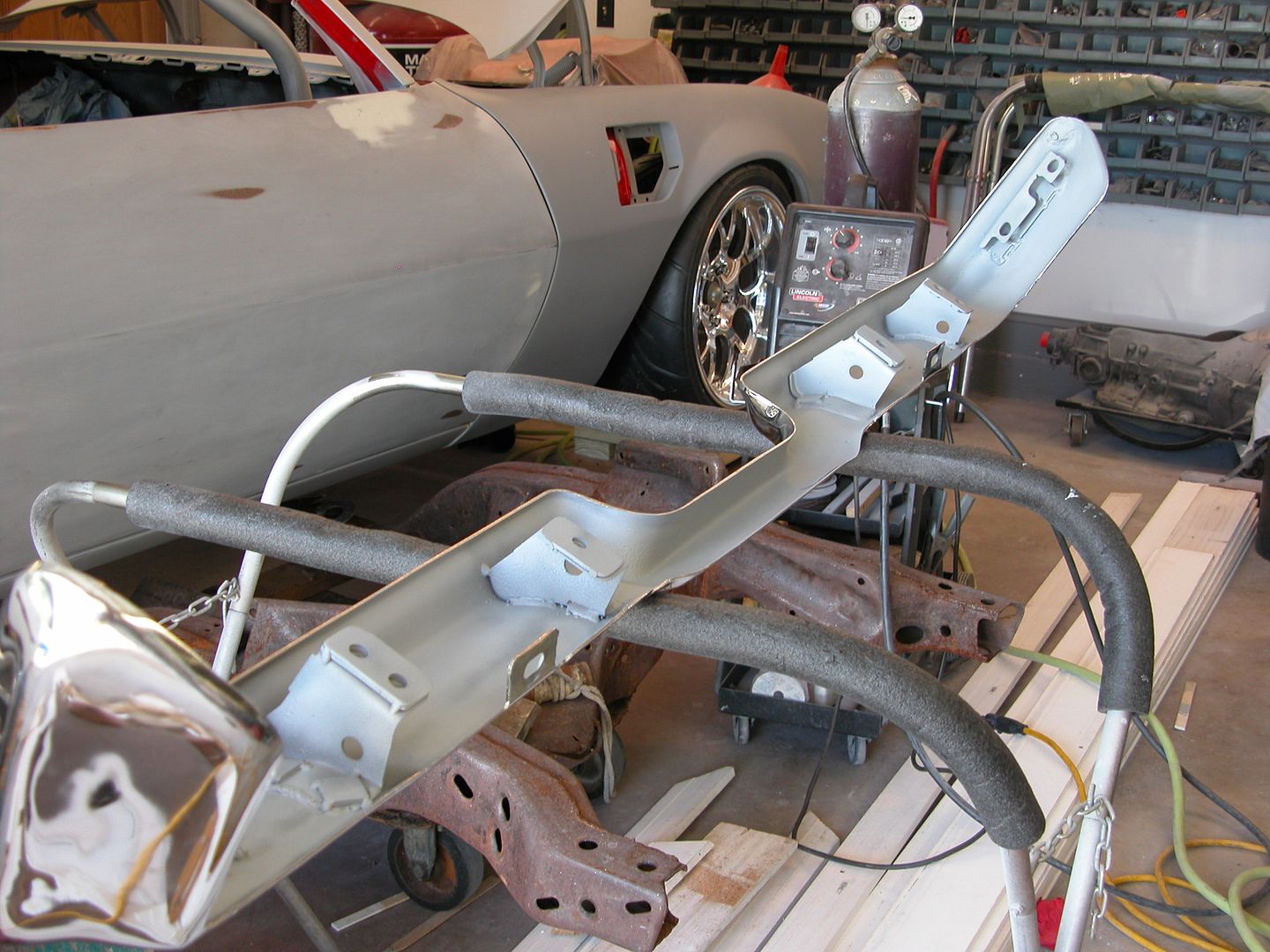

The Elves have been busy! Mocking up all the pieces of the tail panel and bumper to get the best fitment, gaps, etc. took them a minute but it's worth it!

I had my bumper welded up to eliminate the bolts and jack slots many many years ago. I took a used bumper (no repros available back then) that still had the mounting brackets attached to it and sent it to a shop where the brackets were tack welded to the bumper, the bolts removed, plates welded over the holes on the backside, and the bolt holes plug welded from the front. Then the bumper was sent for smoothing and rechroming.

The bumper never really fit quite "right" due to the brackets being adjusted for the car it came off of and the ends had the side droop seen so often on 70-73's. So now was the time to fix things. I ended up making spacers and tack welding them to the bumper brackets to even up the gap along the back and modifying bolts and almost all the bolt holes so the ends can be adjusted properly during final assembly.

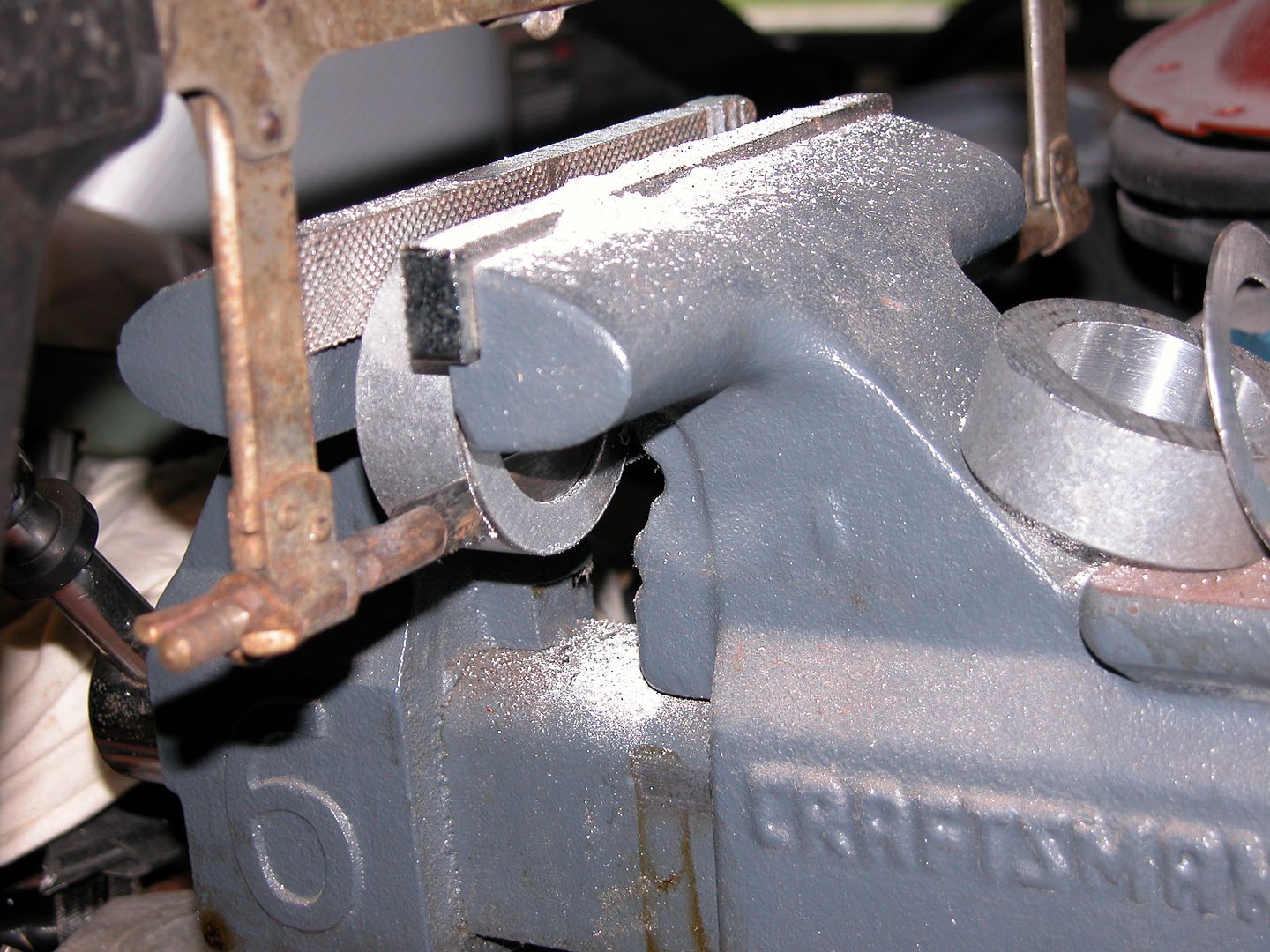

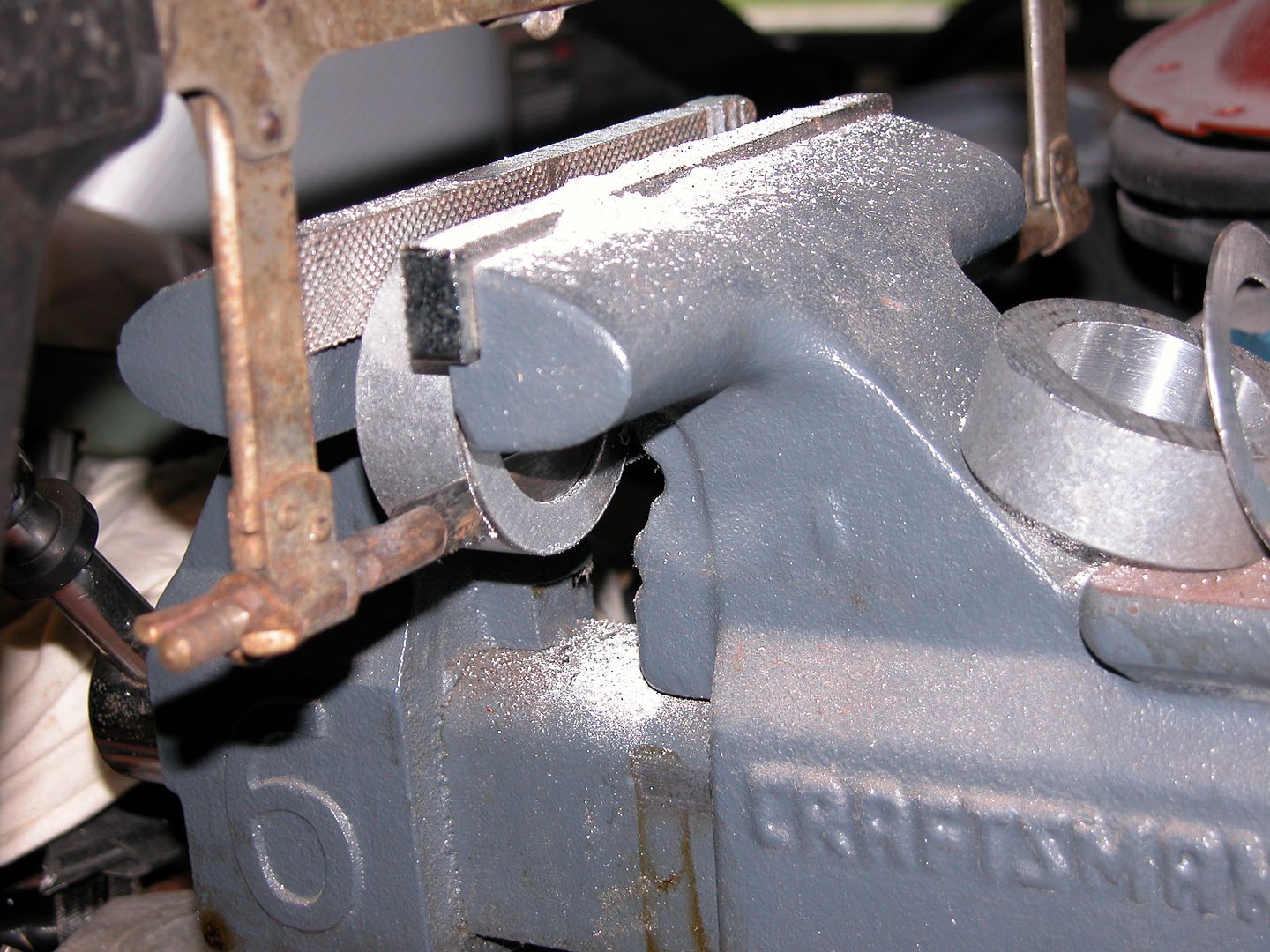

This is the rubber isolator often missing on the center bumper support bracket. Held on by 2 plastic T clips.

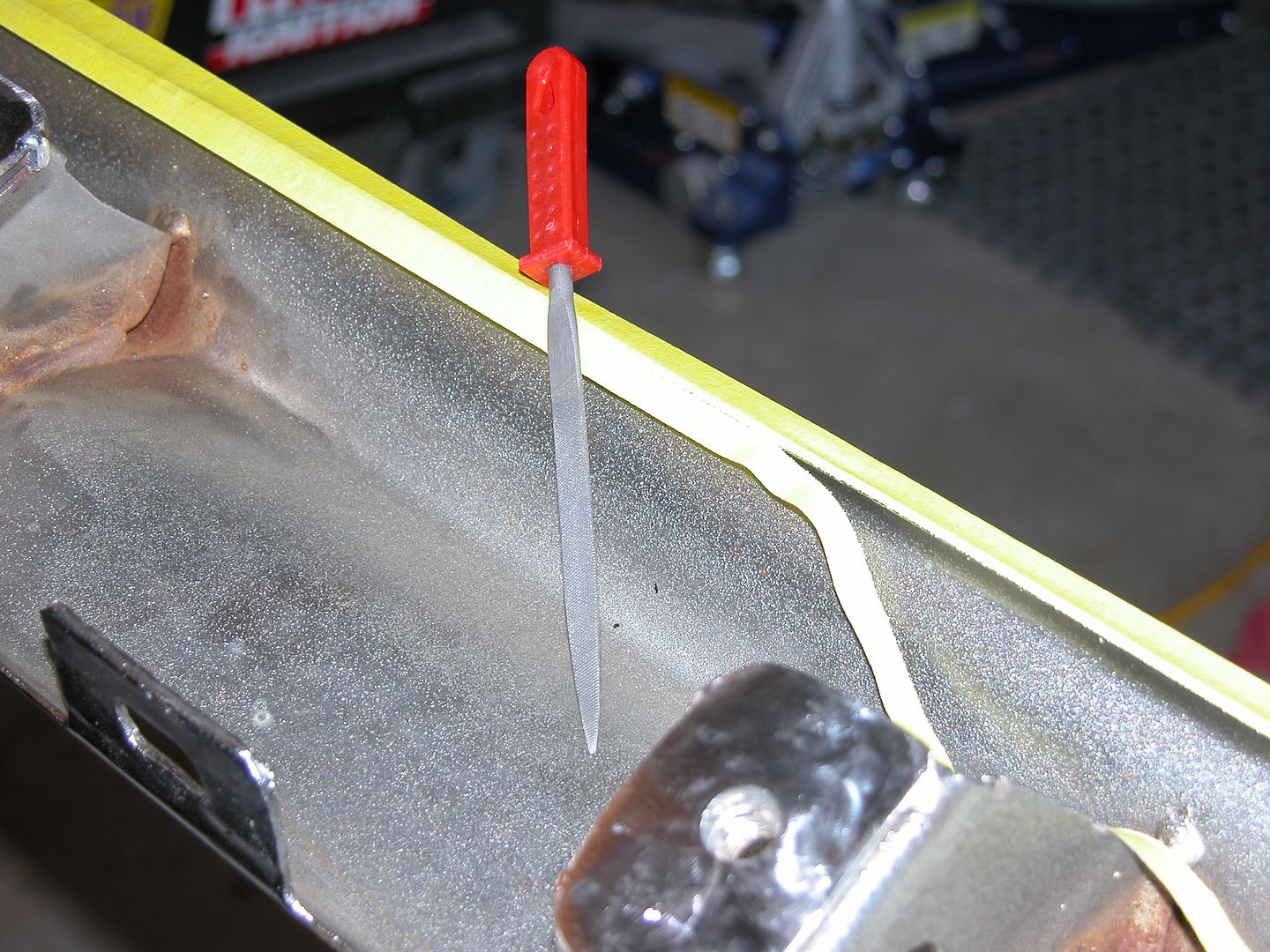

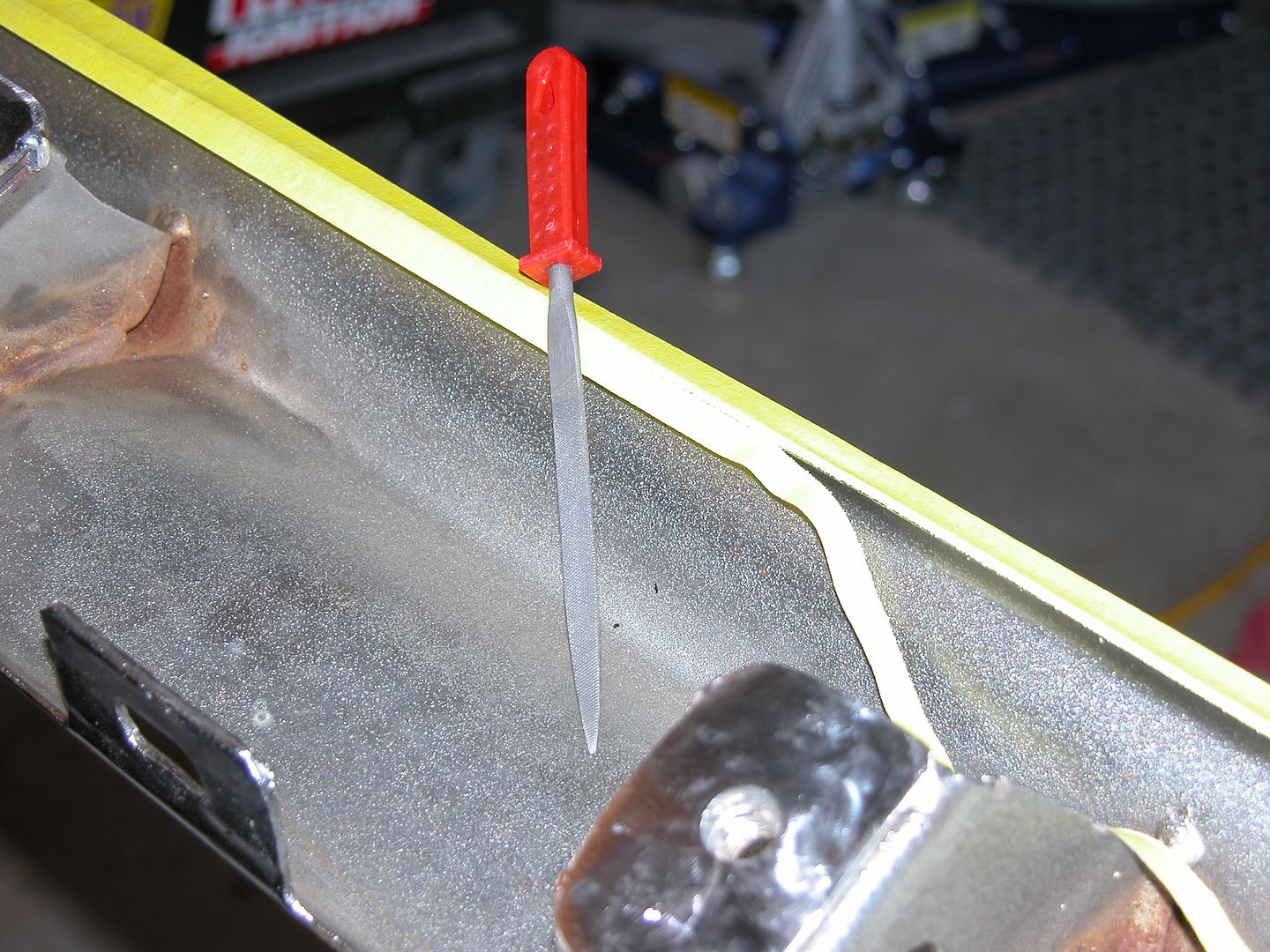

Here's a tip for masking off an edge you can't cut easily with a single edge razor. Rub a file on the tape.

You can see the spacers tack welded to the brackets to create an equal gap to the tail panel in the pic below. Car had no previous rear end damage and none of the sheet metal had been replaced and although the bumper itself had been repaired and replated at least once before I ever owned it it's pretty straight. So I have to assume the fit wasn't very good from the factory judging by the thickness of spacers required and other 70-73 birds I've seen and dealt with.

I had my bumper welded up to eliminate the bolts and jack slots many many years ago. I took a used bumper (no repros available back then) that still had the mounting brackets attached to it and sent it to a shop where the brackets were tack welded to the bumper, the bolts removed, plates welded over the holes on the backside, and the bolt holes plug welded from the front. Then the bumper was sent for smoothing and rechroming.

The bumper never really fit quite "right" due to the brackets being adjusted for the car it came off of and the ends had the side droop seen so often on 70-73's. So now was the time to fix things. I ended up making spacers and tack welding them to the bumper brackets to even up the gap along the back and modifying bolts and almost all the bolt holes so the ends can be adjusted properly during final assembly.

This is the rubber isolator often missing on the center bumper support bracket. Held on by 2 plastic T clips.

Here's a tip for masking off an edge you can't cut easily with a single edge razor. Rub a file on the tape.

You can see the spacers tack welded to the brackets to create an equal gap to the tail panel in the pic below. Car had no previous rear end damage and none of the sheet metal had been replaced and although the bumper itself had been repaired and replated at least once before I ever owned it it's pretty straight. So I have to assume the fit wasn't very good from the factory judging by the thickness of spacers required and other 70-73 birds I've seen and dealt with.

Strictly Attitude

solid fixture here in the forum

looking really good

NOT A TA

reliable source of info

Thanks John!

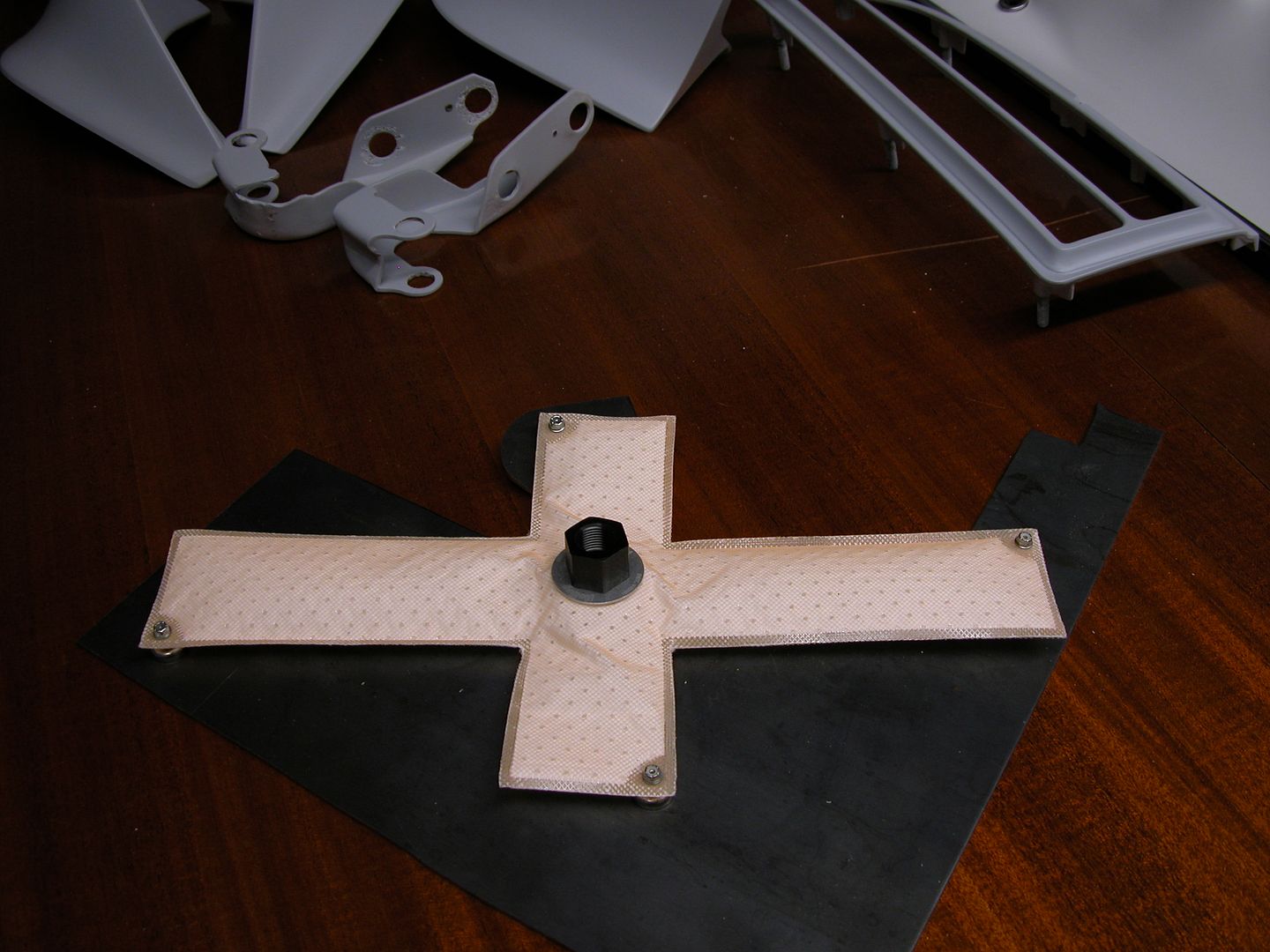

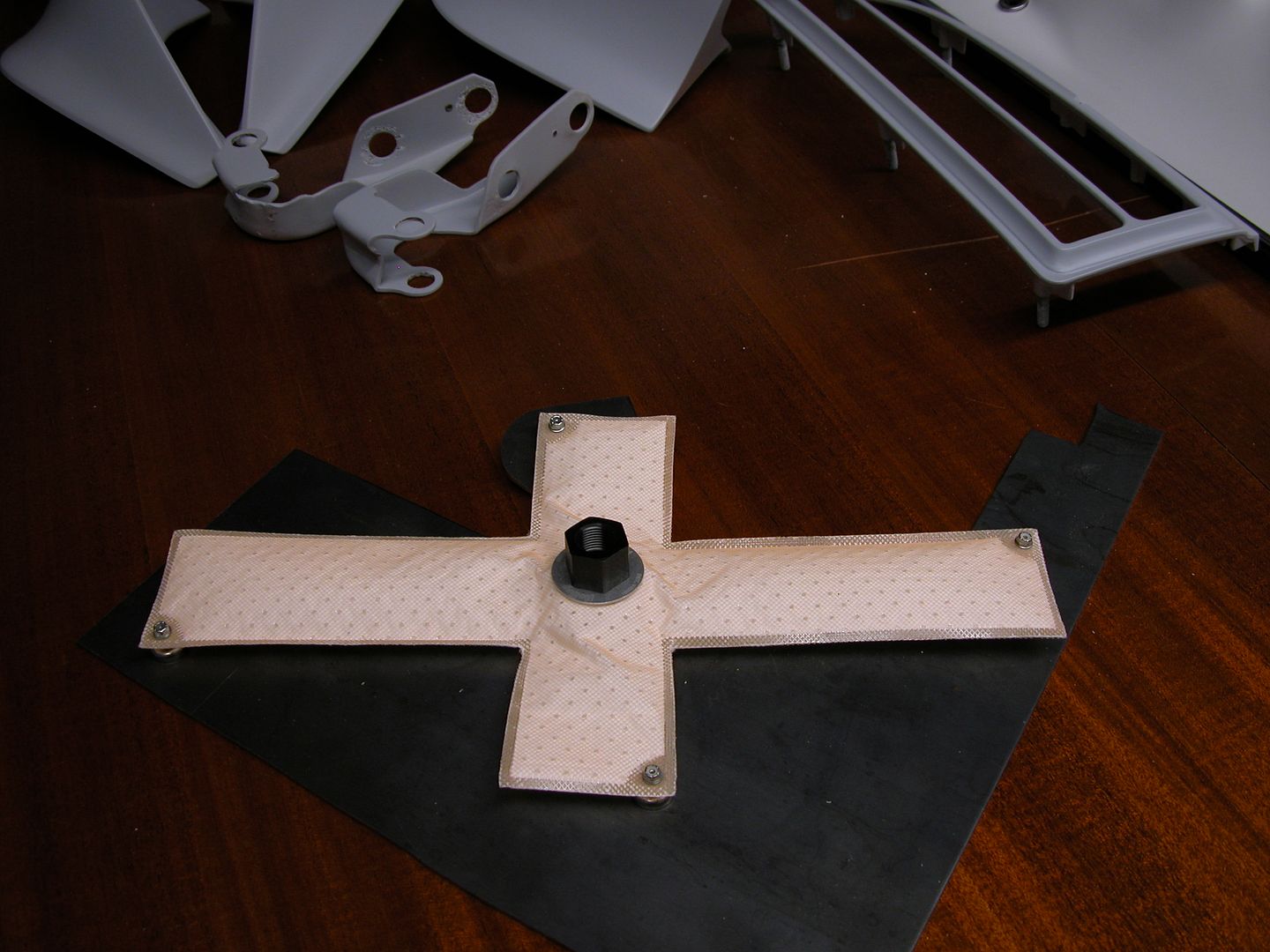

Back in the fall Holley introduced a new product at the SEMA show, the Holley Hydramat. It's a product that mounts in the bottom of a fuel tank and if the fuel in the tank touches any part of the Hydramat the fuel will be sucked in even if no gas is touching the rest of the hydramat.

Holley started shipping about a month ago so I ordered one and got it a couple weeks ago so I thought I'd show it here. Will post about it again when I get it set up in the tank. Cost of mine was a couple hundred bucks. Seems expensive but to save the same weight (on track) with lightweight parts would cost more

This looked like a good product for me to try in my stock unbaffled gas tank until I can install a properly mounted and protected fuel cell. It'll allow me to save weight by keeping less fuel in the car on road courses without risking sucking air in high G corners, reduce the pendulum effect of fuel sloshing in the tank, be safer if there's a fire because less fuel in the car, and since it's also a filter I eliminate the canister fuel filter I've been using also saving weight.

I got the magnet kit for mounting the mat in the tank and will need to install submersible fuel line instead of the stock tube and sock strainer in the tank. Holley makes other sizes and shapes of the mat as well as types of mounting setups for tanks made out of other materials.

Back in the fall Holley introduced a new product at the SEMA show, the Holley Hydramat. It's a product that mounts in the bottom of a fuel tank and if the fuel in the tank touches any part of the Hydramat the fuel will be sucked in even if no gas is touching the rest of the hydramat.

Holley started shipping about a month ago so I ordered one and got it a couple weeks ago so I thought I'd show it here. Will post about it again when I get it set up in the tank. Cost of mine was a couple hundred bucks. Seems expensive but to save the same weight (on track) with lightweight parts would cost more

This looked like a good product for me to try in my stock unbaffled gas tank until I can install a properly mounted and protected fuel cell. It'll allow me to save weight by keeping less fuel in the car on road courses without risking sucking air in high G corners, reduce the pendulum effect of fuel sloshing in the tank, be safer if there's a fire because less fuel in the car, and since it's also a filter I eliminate the canister fuel filter I've been using also saving weight.

I got the magnet kit for mounting the mat in the tank and will need to install submersible fuel line instead of the stock tube and sock strainer in the tank. Holley makes other sizes and shapes of the mat as well as types of mounting setups for tanks made out of other materials.

8

87vette81big

Guest

That Holley Hydramat is neat stuff.

8

87vette81big

Guest

I would like to try the Holley Hydramat myself .

Its priced outside of the budget plans.

Street Racing and Drag Racing is my Cup of Tea '70 Bird Man.

The Latest and Greatest by Corvette has failed. All Home builds too.

Hellcats still #1.

1970 Is a Good Year for Firebirds Trans Ams.

I am going to fabricate a 5/8 " stainless Fuel pickup pipe line for my T/A.

Have a few feet left over of 5/8" stainless tubing from a One off project a few years ago.

Its priced outside of the budget plans.

Street Racing and Drag Racing is my Cup of Tea '70 Bird Man.

The Latest and Greatest by Corvette has failed. All Home builds too.

Hellcats still #1.

1970 Is a Good Year for Firebirds Trans Ams.

I am going to fabricate a 5/8 " stainless Fuel pickup pipe line for my T/A.

Have a few feet left over of 5/8" stainless tubing from a One off project a few years ago.

NOT A TA

reliable source of info

I would like to try the Holley Hydramat myself .

Its priced outside of the budget plans.

Street Racing and Drag Racing is my Cup of Tea '70 Bird Man.

The Latest and Greatest by Corvette has failed. All Home builds too.

Hellcats still #1.

1970 Is a Good Year for Firebirds Trans Ams.

I am going to fabricate a 5/8 " stainless Fuel pickup pipe line for my T/A.

Have a few feet left over of 5/8" stainless tubing from a One off project a few years ago.

Are you using larger fuel lines now? 5/8" is big! What fuel pump are you running

When I build a new engine with more power I'll be putting in a new fuel system also at the same time. Probably use all 1/2" tubing with a RobbMc pump to get away from running an electric pump. I've been running a Holley blue.

http://www.robbmcperformance.com/products/pontiac1100.html

When I do that I'll probably have to buy a new Hydramat to switch from the 3/8" to 1/2" fitting.