I'm always amazed at how few guys

(even myself ) who really thought things through when they first start in the hobby, about how exactly you access that power curve)

think it through, what are you doing at 2500rpm-4500 rpm, your daily driving or maybe on the highway or maybe passing a different car on the freeway

you rarely have to depress the throttle more than 2/3rds to drive like that, and it only requires about 40hp to maintain cruise speed, at 65 mph in most cars

you'll barely be using any of the potential torque or that power curve in use if your daily driving on the streets in daily transportation,

50-70 hp volks wagons can cruise effortlessly at 70mph, when you want to access that power curve your using the car in (performance mode)

I.E. your street racing or impressing a buddy while passing a car or punching it on the freeway on ramp, or reducing tire tread to expensive smoke in some parking lot, (where's the tach then??) (its in that 4500rpm-6200rpm power band)where you'll like having the power, you don't need nor can you use even 1/2 the potential torque either combo provides at 1/4-2/3rds throttle so in that power range added torque is far less use full, unless your big on throwing gravel and spinning tires from a rolling start at a stop sign.... if you want to smoke the treads off you'll push the throttle down to full on the floor... look at the tach....

(where's the tach then??) (its in that 4500rpm-6200rpm power band)where you'll like having the power.

as RICK, his engine in about a 2000 lb T-bucket produces impressive power but he can briskly accelerate using just 1/2 throttle, if the rpms hit 4500rpm plus, he's in for what could be a basically aim down the highway and hold on ride., sure he has nearly or a bit over 500 hp, but he can barely use it, and rarely can use it if using the car as transportation vs racing.

while its true you may only have 400ft lbs and 250 hp at 2500rpm-3500rpm where you spend 90% of your drive time, you'll rarely use 2/3rds of that power available while you drive, even briskly drive, on the streets, and if racing the rpms on the tach will be noticeably higher,

remember 50-70 hp volks wagons can cruise effortlessly at 70mph,

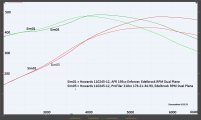

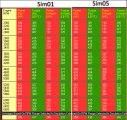

the problem, some guys have is they forget about the lower rpm driveability issues and select a cam or other components that are designed to produce impressive PEAK power but severely compromise lower rpm driveability, that's not the case with any of the combos discussed here!

as always every choice made is a compromise some where either in your time, wallet or the cars performance or durability