You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unforgiven Project

- Thread starter Unforgiven

- Start date

Unforgiven

solid fixture here in the forum

Unforgiven

solid fixture here in the forum

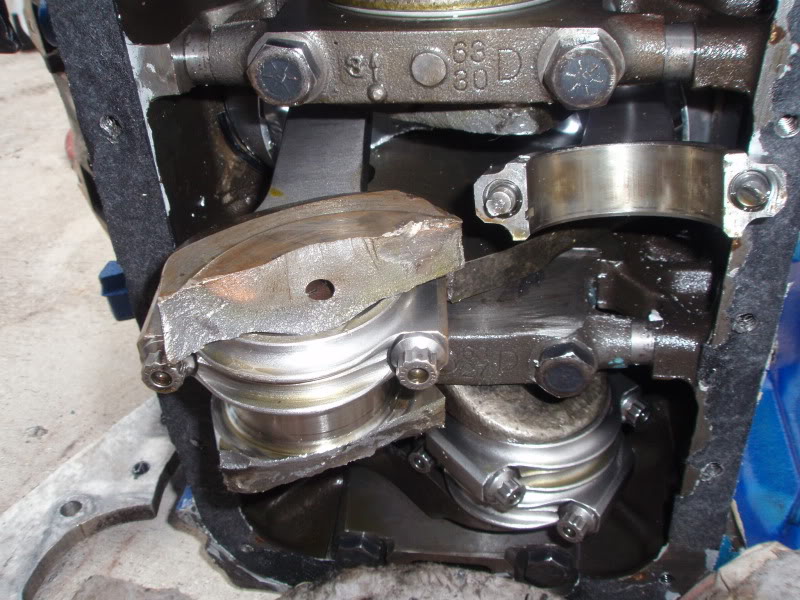

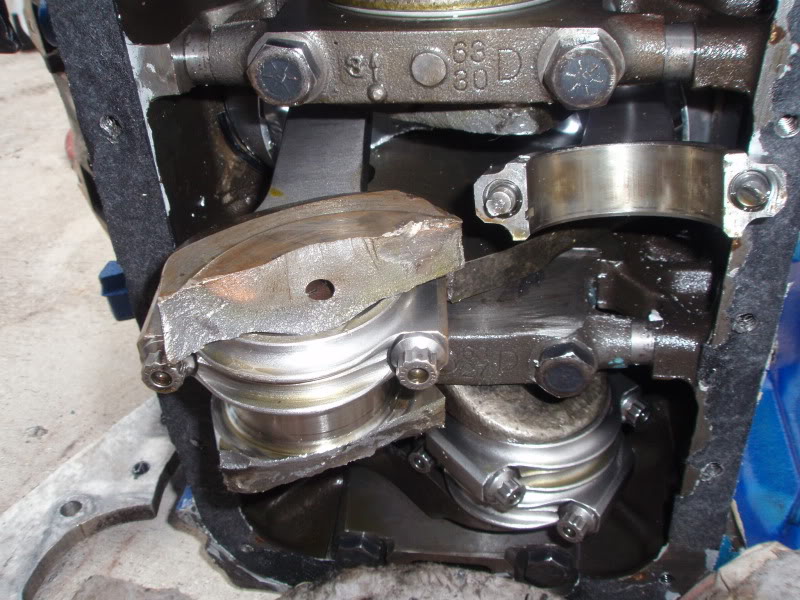

The rod journal had a line but it is not a scratch. After seeing the bearing I was surprised. But... the main center journal did have some grooves that I could just barely feel with whats left of my fingernails. I did not get a pic of the center main but I did get one of the rod journal. I will finish the tear down tonight

and have a few more pics.

and have a few more pics.

Attachments

Maniacmechanic1

solid fixture here in the forum

The crankshaft was deflecting flexing severe under boost.

Next time around use a True Race oil.

20w50 a good choice.

It's a Race engine.

Next time around use a True Race oil.

20w50 a good choice.

It's a Race engine.

Maniacmechanic1

solid fixture here in the forum

Clean up the ports.

Port velocity not so important with boost.

Kinda moot with race Chevy.

Drag gears used.

More important Race Pontiac V8 Put on the Street port velocity.

Port velocity not so important with boost.

Kinda moot with race Chevy.

Drag gears used.

More important Race Pontiac V8 Put on the Street port velocity.

Maniacmechanic1

solid fixture here in the forum

Not liking that block.

Scary.

Look for a used Dart Little M.

Dirt track guys use.

Street stockers often.

We had 1.

Stroker 419 ci combo.

4bbl we had over 600 hp.

2bbl knocked down 55-75 hp.

$1k a good price used.

Scary.

Look for a used Dart Little M.

Dirt track guys use.

Street stockers often.

We had 1.

Stroker 419 ci combo.

4bbl we had over 600 hp.

2bbl knocked down 55-75 hp.

$1k a good price used.

Unforgiven

solid fixture here in the forum

I did on mine. How much, probably not a whole lot, but enough little things make a big

thing ! This goes for the intake ports as well.

Thanks Rick. I did not see where it would hurt, but I like to hear other view points.

Maniacmechanic1

solid fixture here in the forum

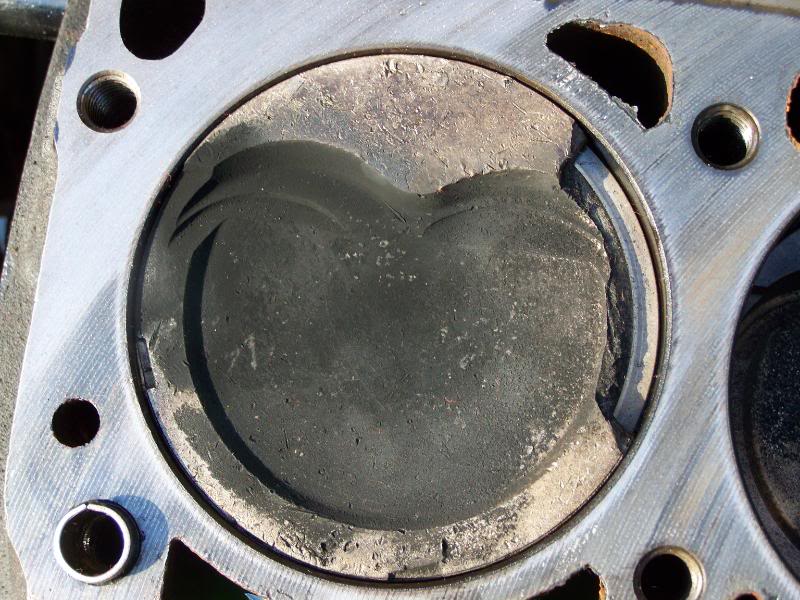

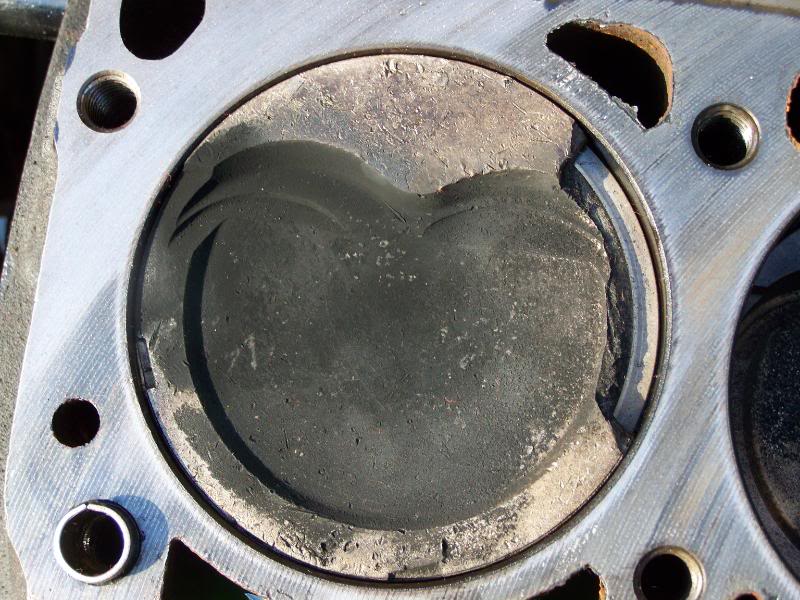

The score in the cylinder wall I experienced too.

It's the plasma only top piston ring coming apart.

Molyedium metal comes free and fuses with the TRW SM75 alloy that has silicon in it.

SM75 Is similar to modern 4032 alloy forged pistons..silicon content high.

Acts like a carbide burr cutter.

Score in the cylinder wall.

Detonation took place.

Super Heat. Super hot uncontrolled multiple flame fronts colliding together.

Give it octane a Race engine.

2618 pistons best. No silicon in them.

It's the plasma only top piston ring coming apart.

Molyedium metal comes free and fuses with the TRW SM75 alloy that has silicon in it.

SM75 Is similar to modern 4032 alloy forged pistons..silicon content high.

Acts like a carbide burr cutter.

Score in the cylinder wall.

Detonation took place.

Super Heat. Super hot uncontrolled multiple flame fronts colliding together.

Give it octane a Race engine.

2618 pistons best. No silicon in them.

Unforgiven

solid fixture here in the forum

It may have something to do with that Q16 fuel I was using too.

I was using VR1 20W50 oil also. timing was set at 33* with nothing pulled on boost.

I'll look at the ring tonight when I pull the piston.

I was using VR1 20W50 oil also. timing was set at 33* with nothing pulled on boost.

I'll look at the ring tonight when I pull the piston.

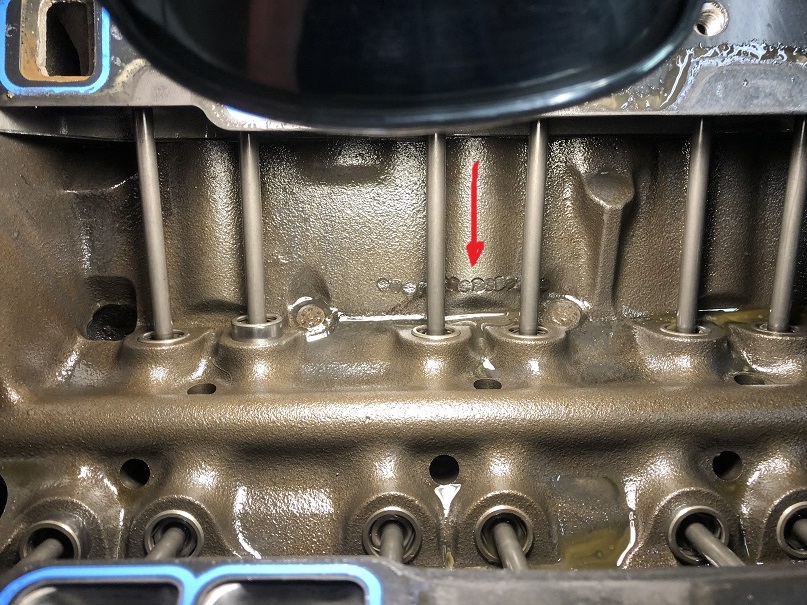

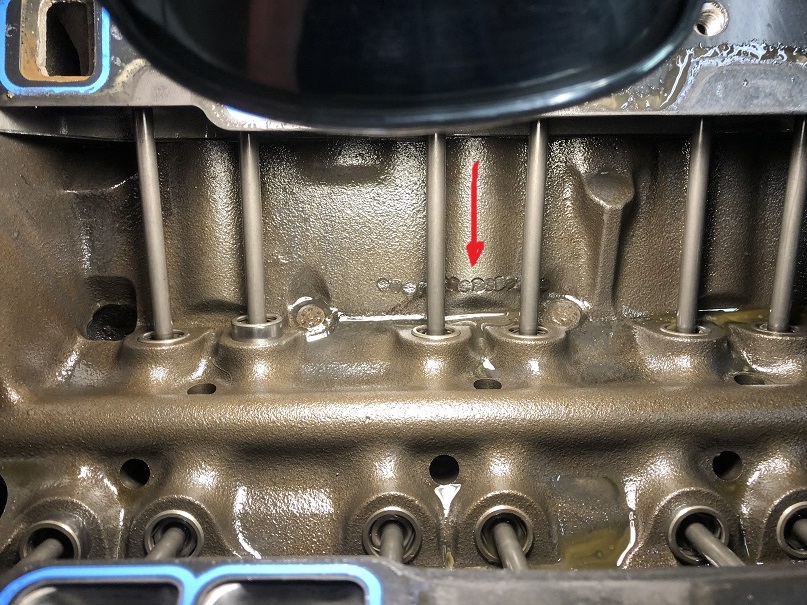

the wear on the center main

would tend to indicate either the block needs to be line honed ,

and main caps may be flexing

or the crank is marginally bent from being true strait, the pinned area in the lifter gallery also tends to support the idea,

the block flexes or is in need of a line hone

between the two, Id suggest upgrading too a different block is a good option, and Id suggest the local machine shop closely inspect the crank assembly and bearing journals

would tend to indicate either the block needs to be line honed ,

and main caps may be flexing

or the crank is marginally bent from being true strait, the pinned area in the lifter gallery also tends to support the idea,

the block flexes or is in need of a line hone

between the two, Id suggest upgrading too a different block is a good option, and Id suggest the local machine shop closely inspect the crank assembly and bearing journals

Last edited:

Unforgiven

solid fixture here in the forum

Thank you for that explanation Grumpy. I am waiting for a man to get back from Florida next week who may have a Dart for sale. I am crossing my fingers.

Maniacmechanic1

solid fixture here in the forum

Need to pull timing back when boost comes on or Nitrous oxide on.It may have something to do with that Q16 fuel I was using too.

I was using VR1 20W50 oil also. timing was set at 33* with nothing pulled on boost.

I'll look at the ring tonight when I pull the piston.

Some basic charts are around here for guidelines power adder to retard ignition timing.

Needs updates.

Bit of Racers secrets. Trial and error.

Find what works and say Notta nothing.

old rule of thumb, for each pound of manifold boost its generally a good idea to pull out 1-1.5 degrees of total ignition spark, advance

then read the plugs and check the knock sensor counts carefully for indications of detonation

then read the plugs and check the knock sensor counts carefully for indications of detonation

Unforgiven

solid fixture here in the forum

I have a MSD boost master planned with the new build. Pretty much everything is going to be new along with alot of upgrades.

If I can get that Dart block, it will push my build toward the fall for lack of funds. That block ain't going to be free. But, it will be better all the way around than from what I have. There are always setbacks arn't there?! Patients will pay big dividends in this case though!

If I can get that Dart block, it will push my build toward the fall for lack of funds. That block ain't going to be free. But, it will be better all the way around than from what I have. There are always setbacks arn't there?! Patients will pay big dividends in this case though!

always think logically, theres always a huge desire to press forward using existing O.E.M. components you have on hand,

and in many cases those component may serve you well,

but theres absolutely no logical reason to flush more cash,

in parts and machine work into a block that shows indications it may not stand up to the stress levels that already show,

signs it may fail ... especially when the goal is further increasing the power output levels and associated stress.

what you might gain in the short term in benefits is very likely to result in a major cascade of parts failing,

where you may be lucky to save the valve covers and water pump.

yeah! it will never happen to your engine!

well, that might not be 100% true

why cast cranks and high stress and rpm are a bad idea

and in many cases those component may serve you well,

but theres absolutely no logical reason to flush more cash,

in parts and machine work into a block that shows indications it may not stand up to the stress levels that already show,

signs it may fail ... especially when the goal is further increasing the power output levels and associated stress.

what you might gain in the short term in benefits is very likely to result in a major cascade of parts failing,

where you may be lucky to save the valve covers and water pump.

yeah! it will never happen to your engine!

well, that might not be 100% true

why cast cranks and high stress and rpm are a bad idea

Last edited:

Unforgiven

solid fixture here in the forum

yeah! it will never happen to your engine!

Famous last words!

Unforgiven

solid fixture here in the forum

Someone school me on the GM bow-tie blocks. Are they aftermarket blocks. Will they hold up to 700hp.

Unforgiven

solid fixture here in the forum

Grumpy... may I have permission to share those broken crank pics with my wife.

I think visual evidence would help me explain to her why I need a bigger budget!

I think visual evidence would help me explain to her why I need a bigger budget!

I can,t make any decisions for you, but I can point out what has happened in the past , too others,

and suggest the proven safer routes others have found over decades,

pictures are posted there to make it easier to understand past mistakes others have made,

you might want too avoid duplicating choices that cost them a great deal of time,

and effort and cash to correct or rebuild from

and suggest the proven safer routes others have found over decades,

pictures are posted there to make it easier to understand past mistakes others have made,

you might want too avoid duplicating choices that cost them a great deal of time,

and effort and cash to correct or rebuild from

Last edited: