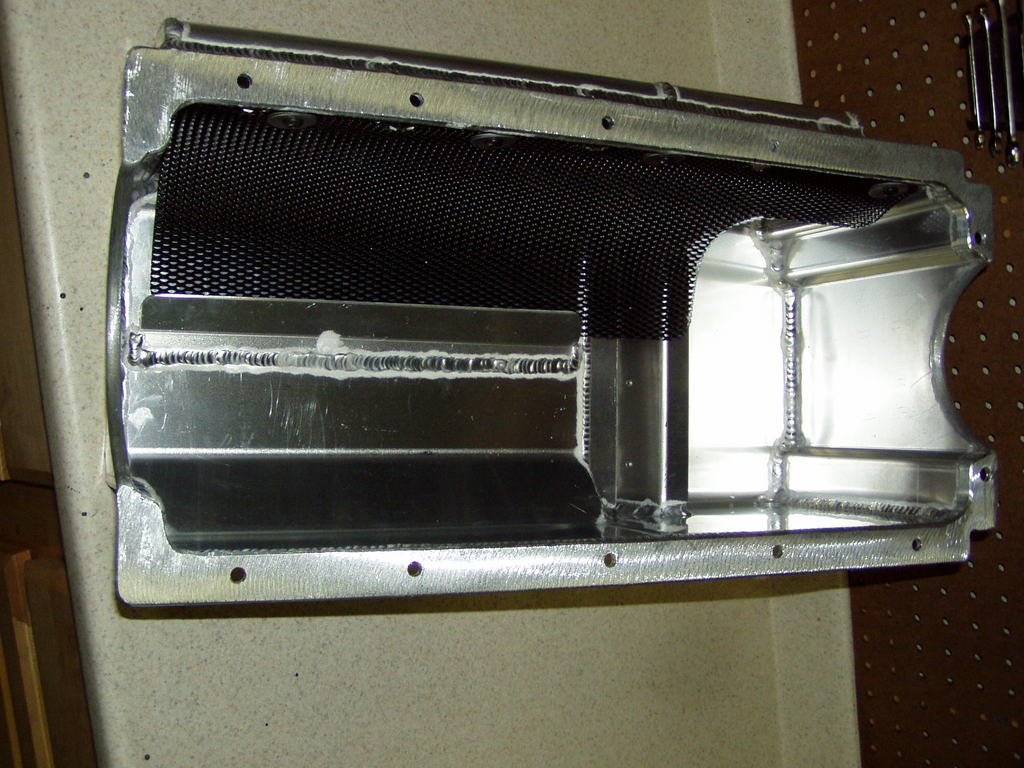

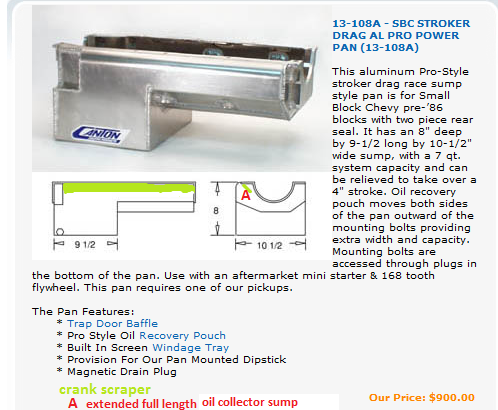

step (1) on any custom oil pan is youll need a stock oil pan to start with, that you can use to supply the oil pan rails , then, you measure distance from block rails to bottom of oil pump pick-up and pump,you will use , obviously your not easily going to make an oil pan any shallower than about 3/8" deeper than the depth the oil pump extends into the oil pan below the block oil pan rails, and on some oil pump designs the oil pump pick-up must be lower than that distance , on the big block chevy pump the oil pump pick- up can be set about at the same distance from the oil pump base, from the oil pan floor.

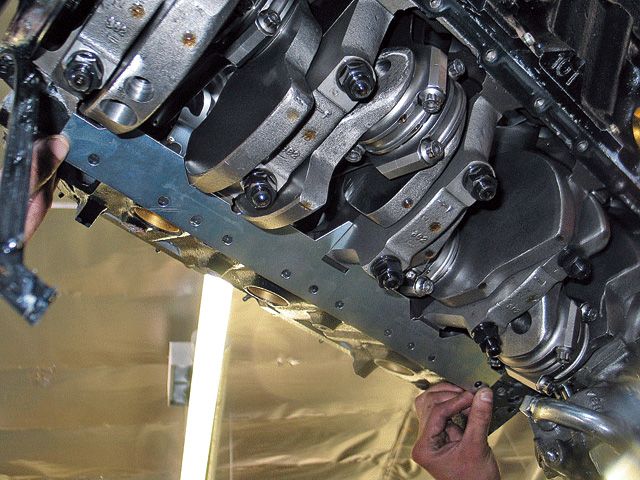

it should also be obvious that having the car the oil pan will be used in to measure clearances is critical, and youll need the headers installed and steering linkage etc.naturally a custom sump requires you to measure for header and suspension clearances, don,t forget to leave access for the oil filter and starter to check clearances on the oil pan,keep in mind you can add auxiliary oil coolers or remote mount oil filters to add extra oil capacity.

http://garage.grumpysperformance.co...mps-and-driveway-enterances.10516/#post-83070

small block oil pump pick-up exit the oil pump bottom plate big block pump pick-ups exit the pump body

in either case your limited and can rarely build a oil pan shallower than 7" in depth , but the length and width has options depending on the frame,suspension, oil filter, headers etc.

STEP 2 leave room to get to the oil filter, and oil pan bolts so they can be tightened or loosened, , if you can,t access the oil pan bolts with the engine in the car youll hate that oil pan and the leaks it is sure to eventually have and do not have the headers , frame or suspension or anything else touch the oil pan, and leave at lease 4" of ground clearance under the oil pan floor with YOUR WEIGHT IN THE CAR

step 3

a oil drain , located on a back vertical lower corner where you can access it and remove it easily when required is a nice feature, but remember to think it thru, if the block saver plate, bell housing, or flywheel is in the way , you have a problem, try not to use lower horizontal surfaces as lower horizontal surfaces tend to get scraped off if they stick down below the oil pan floor level

Spring Sale ✨Free shipping from $60✨ "Good cutter! More than I expected." ——Justin J. JUST GET EVERYTHING DONE IN SECONDS FASTER & SAFER SHARP BLADE EASY TO USE FAST CUTTING GENERAL MODEL Electric Drill Shears Attachment Cutter Nibbler $87.99$39.99UP TO 55% OFF YES! I WANT TO ORDER NOW 1h 32m...

www.peachloft.com

www.peachloft.com

www.peachloft.com