I'm glad and relieved to say that today's start-up exceeded expectations ! In fact there was very little drama lol.

I've got a couple videos that I'll try to link here but to summarize...

- Last checks and a dry crank before connecting the HEI.

- it fired immediately but died a couple times, no big deal as I was moving the distributor a bit and it needed a little more gas

- third time it fired up, we ran it about 1500 rpm for 15 minutes, good oil pressure, smooth, sounded great

- carb was fine, no flooding, nice throttle response

- I didn't use a timing light, this was just for initial running. Used the ear gauge but I'll time it accurately next time

- I'll poke around to see if there's any drips or drabs but a quick look shows nothing

Observations...

- I think the Morel lifters can use about another quarter turn but not sure. I can hear them a bit but it's not excessive. I've read that they tend to be a bit noisier.

- I do hear a bit of lifter clatter but right now I'm not going to rush to crank the rockers down another quarter turn. Lots of oil info out there about Morel too. I'm wondering if the tie bars contribute to that noise.

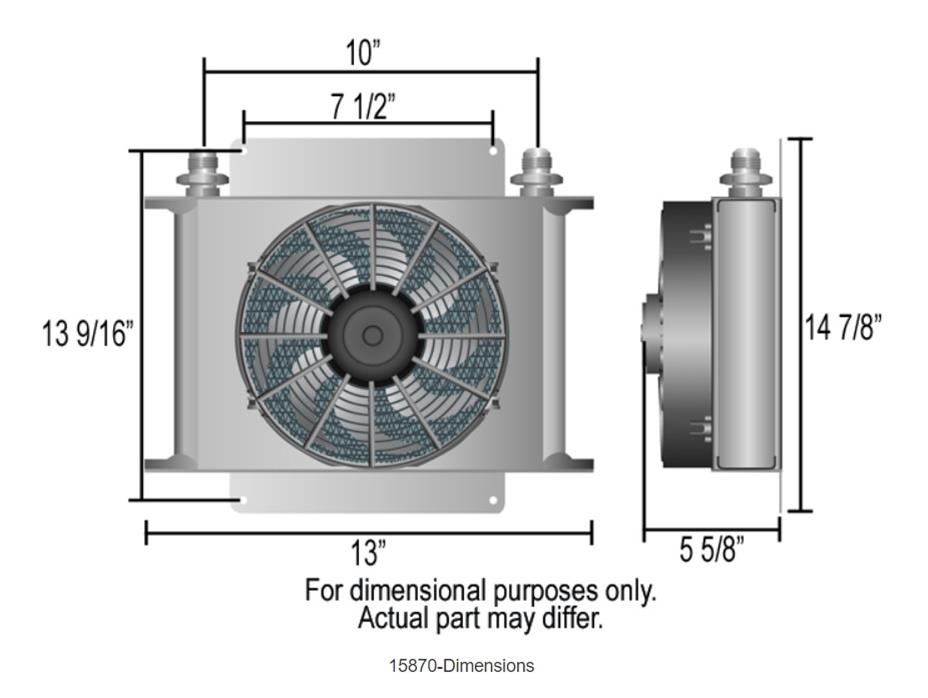

- my bounce house fan wasn't optimal. Engine stabilized at 210 but I could see and feel the radiator was only getting a center cone of air hitting it.

- timing may be contributor to engine temp, since I just moved distributor to where it sounded the best

- I'm on the fence about a larger radiator but first I'll get the twin electric fans installed, then figure further after I see results.

Guys, I hope you share in the glory here. This was an easy start-up with a very solid sounding engine. I need to get used to the different exhaust tone with the different cam overlap, has that little bumpy bumpy at idle.

Additional motivation now to get the cooling system finished and rebuild the trans, but as you've been there too, this was a big milestone.

Thank you again.