You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

tumble and swirl, quench & squish

- Thread starter grumpyvette

- Start date

and yeah, watching the videos does help prevent you from having problems,

if you take the info/knowledge you gained,

and use it to your advantage. that requires measuring

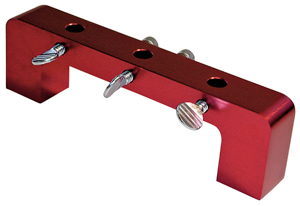

Powerhouse Products POW101310 Powerhouse Products Dial Indicator Deck Bridges | Summit Racing

Free Shipping - Powerhouse Products Dial Indicator Deck Bridges with qualifying orders of $109. Shop Dial Indicator Stands at Summit Racing.

Summit Racing SUM-900061 Summit Racing™ Dial Indicators | Summit Racing

Free Shipping - Summit Racing™ Dial Indicators with qualifying orders of $109. Shop Dial Indicators at Summit Racing.

or researching, and adding instructions or tips on both new and older existing threads,

one problem this seems to cause is that I frequent go through these component modification threads and realize I may be missing the best current tool, and thus the U.P.S and AMAZON DELIVERY GUYS spend a good deal of time and I tend to spend cash on constant tool upgrades and acquisitions.. and as a tool junkie,this tends to add up over time! my son says Im constantly watching for package deliveries

or as he said, I seem addicted like a heroin junkie, to getting new tools delivered

Last edited:

here's a few quick concepts (watch all the way through the video)

the fuel octane level, and how effectively you can evenly mix fuel and air before the piston reaches TDC

and the shape and surface area matters.

combustion chamber temps MATTER, cylinder combustion chamber to piston dome clearance matters

the cooler and more compact and centralized you can keep the fuel/air mix,

in the combustion chamber and the more evenly mixed you can keep that fuel/air mix as its being compressed,

the less likely you'll find the rapid compression in the cylinder initiates self ignition,

minimizing the piston to bore clearance, helps prevent piston rock,in the bore to combustion chamber clearance issues

while vizzard is quoting quench distances used in the 20 thousandth range Id suggest you stay above .035 simply due to having seen lots of evidence of physical piston to head contact on several engines built with mostly OEM parts with quence distances that were less.

getting the correct piston to bore clearance, on your block

always think every step you take in any performance engine build through, logically and don't just jump off the dock head first, financially, without asking detailed questions , and documenting as much as you can in writing, and having a well thought through plan, parts list and time frame...

garage.grumpysperformance.com

Basic Math On Fuel/air Ratios That Gets Ignored

1 cubic foot of air at standard temperature and pressure assuming average composition weighs approximately 0.0807 lbs. (at sea level) that simply means it takes 12.4 cubic feet of air to equal one pound, your best engine torque is generally found at a fuel/air ratio near 12.6:1 , thats 12.6...

garage.grumpysperformance.com

assembling and installing connecting rods/pistons

look closely at the connecting rods one edge of the main bearing are is beveled noticeably more than the other that beveled side faces away from the rod its paired with because it matches the slight radiased bevel of the crank journal many builder class pistons are designed to go in, in either...

garage.grumpysperformance.com

ring gapping and basic piston ring info YOULL NEED

YES YOU NEED TO READ THRU THE LINKS THAT'S WHAT THEY ARE THERE FOR...AND THERE'S A GREAT DEAL OF USEFUL INFO IN THOSE LINKS, https://www.youtube.com/watch?v=iuj9nfQ-LRY&t=33s don,t get over whelmed, make a list and test adjust correct or replace each problem, and check it off the list then move...

garage.grumpysperformance.com

checking piston to valve clearances

this is an old post I got asked to repost, naturally the first step is to install and correctly degree in your cam, http://garage.grumpysperformance.com/index.php?threads/measuring-piston-dome-volume.17255/...

garage.grumpysperformance.com

Copper head gaskets

Gentlemen, An update on Brass head gaskets: They are NOT torque once and forget them. They require retorqueing: after a solid heat cycle you need to brake lose and retorque each head bolt (one at a time) in the correct torqueing pattern. As my engine is going into a G20 Van it is nearly...

garage.grumpysperformance.com

Can you plan for quench

OK here I am looking at my options for a 91-93 octane pump gas streetable. Looking into as many aspects as possible to make things go smooth and end up with what I want in the end. So from my readings quench is good .038-.046 or .044 or .042 depending on which of Grumpy's posts you read lol...

garage.grumpysperformance.com

unshrouding valves, and polishing combustion chambers

I think you missed my point It was a pun intended towards Skipwhite performance..... Short of the long story Skipwhite performance build a motor for me in 2015 fast forward 2018 They built junk from what I have ran into, Grumpy and the gang have gave me all kinds of advice and help so far...

garage.grumpysperformance.com

unshrouding valves, and polishing combustion chambers

I think you missed my point It was a pun intended towards Skipwhite performance..... Short of the long story Skipwhite performance build a motor for me in 2015 fast forward 2018 They built junk from what I have ran into, Grumpy and the gang have gave me all kinds of advice and help so far...

garage.grumpysperformance.com

calculating piston pin height/compression height

" HEY GRUMPYVETTE? I picked up a tall deck,Chevy big block 427, block, at a yard sale and a friend donated a set of 454 .060 pistons Ive got several intakes for big block engines ,both oval and rectangular port, styles, whats it going to take to build a 496 stroker from these components?" it...

garage.grumpysperformance.com

piston to bore clearance

ok first some facts (1)cylinders will not be honed to true round as they will be in use with out the use of a deck plate to simulate and duplicate the bolt clamp stress on the cylinder walls, bores in blocks without a head or deck plate with the bolts or studs torqued to spec are not nearly the...

garage.grumpysperformance.com

Last edited: