some excellent info well worth reading thru

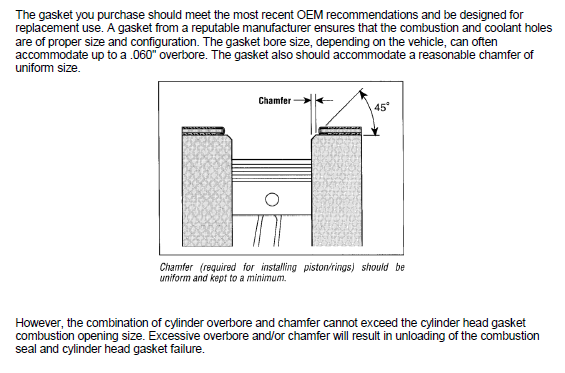

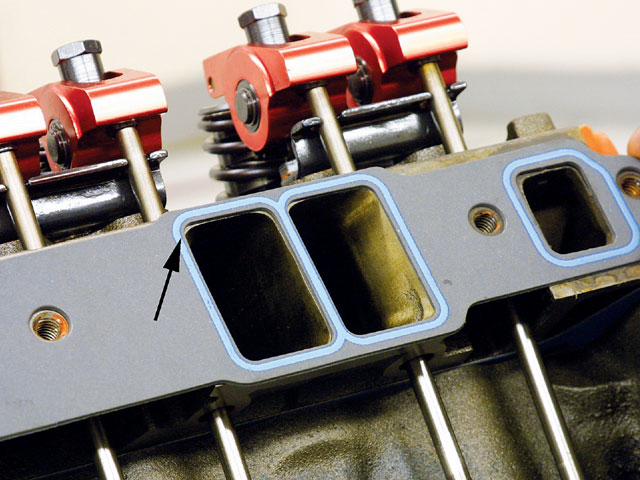

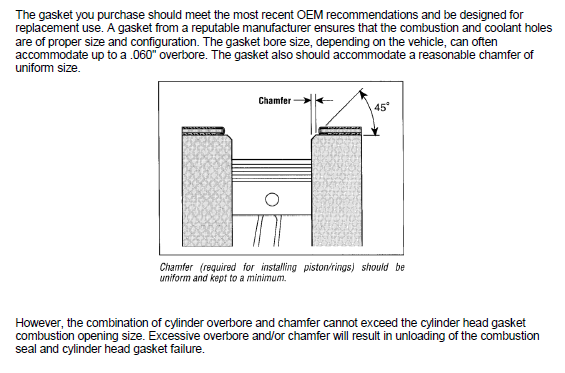

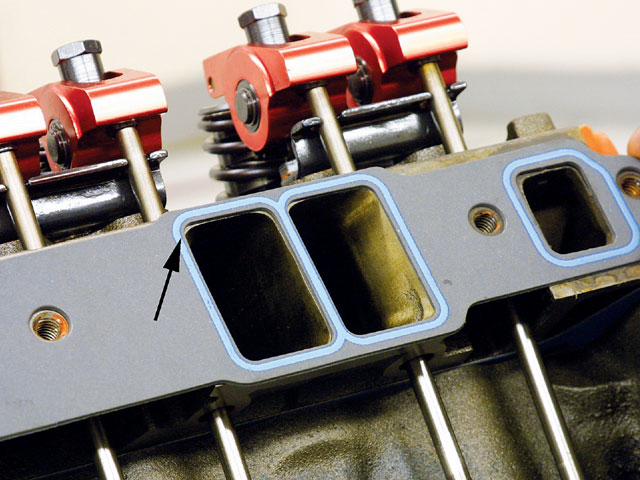

head gaskets are rarely completely round, nore are combustion chambers

you,ll want to place a head gasket you,ll use on the heads and mark the area inside the opening as the only areas you can change,

(notice the gasket fire ring is NOT a perfect circle like many people assume)

ideally you,ll want to un-shroud the valves while opening up the combustion chamber volume, but not extend the combustion chamber past the front edge of the gasket fire ring as that usually causes gasket failure

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/

http://garage.grumpysperformance.com/index.php?threads/can-t-find-matching-pistons.14206/

http://garage.grumpysperformance.com/index.php?threads/piston-related-info.110/

http://garage.grumpysperformance.co...u-thinking-about-your-potential-combos.14607/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-31684

http://www.superchevy.com/how-to/89678-valve-angles/

http://www.enginebuildermag.com/200...ts-what-you-need-to-know-to-go-with-the-flow/

http://johnmaherracing.com/tech-talk/3-angle-valve-job/

http://garage.grumpysperformance.co...chevy-cams-and-a-few-similar-aftermarket.133/

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-60554

READ THRU THIS LINK

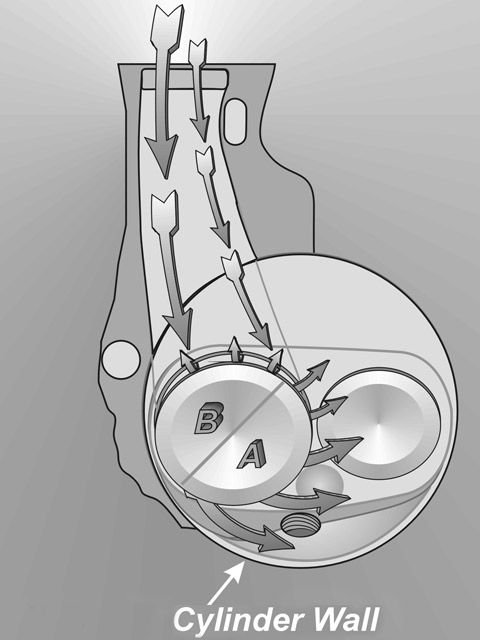

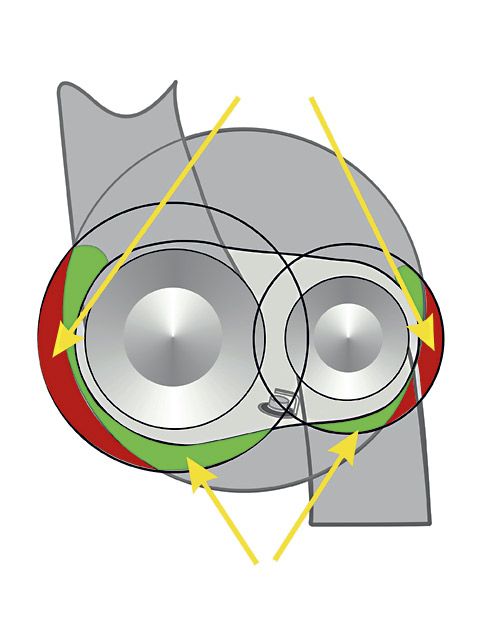

you might have somehow gotten the IN-CORRECT idea that the valve center-line and CYLINDER center-line are exactly matched in a sbc, they are NOT!

plus the valves are angled at a 23 degree angle so the outer valve edges close to the cylinder walls do not drop strait down into the bore as the valves open at the point of the cylinders largest diam. moving the head center-line to move the valve center- line to maximize flow at max valve lift potentially helps performance.

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

the most common mistake made by many people is that they fail to look at an engine as an interconnected group of component sub systems and they don,t realize that changes to a single component, no mater how much potential that component has is not going to allow that component or change in the potential to be realized until all the matched and supporting systems have similar potential.

EXAMPLE ,

the heads may be capable of flowing (x) on a stock engine but with careful selection of a cam with the correct duration and lift, and with a tuned header, and matching valve train mods along with some port and bowl clean-up the resulting improvements can be significantly more impressive.

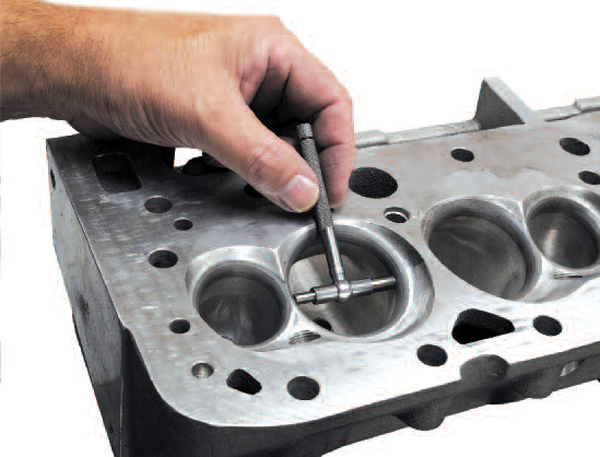

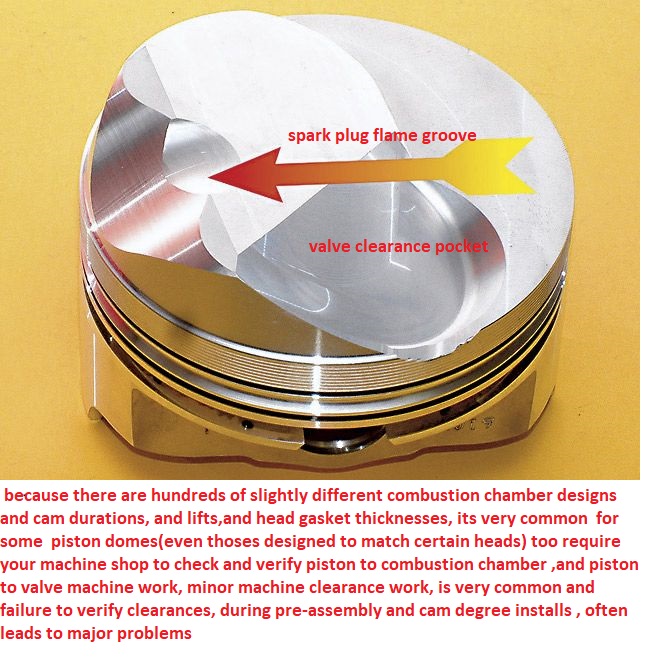

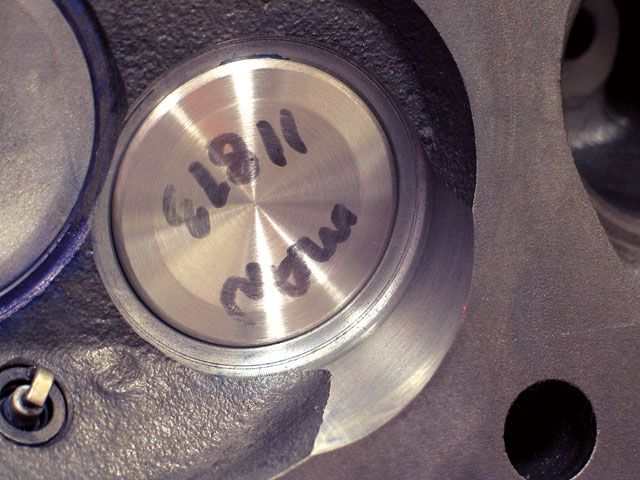

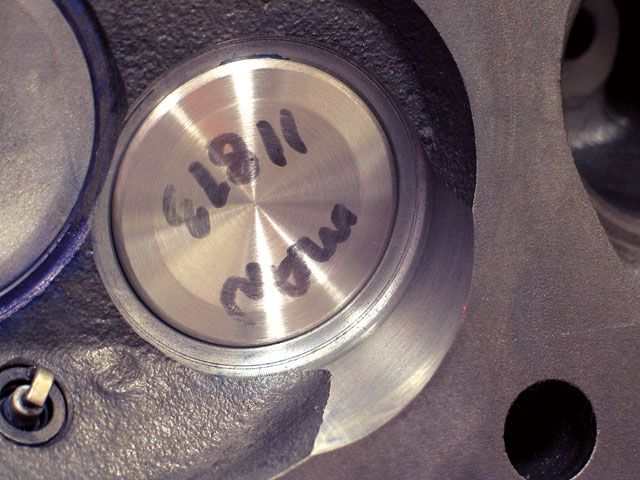

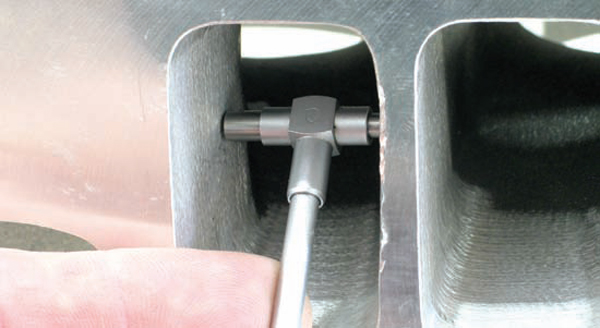

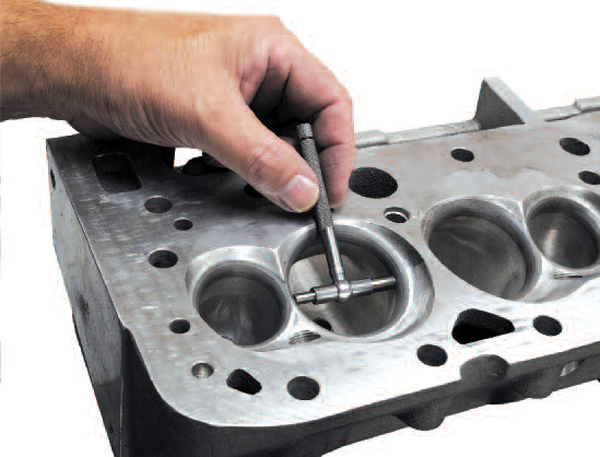

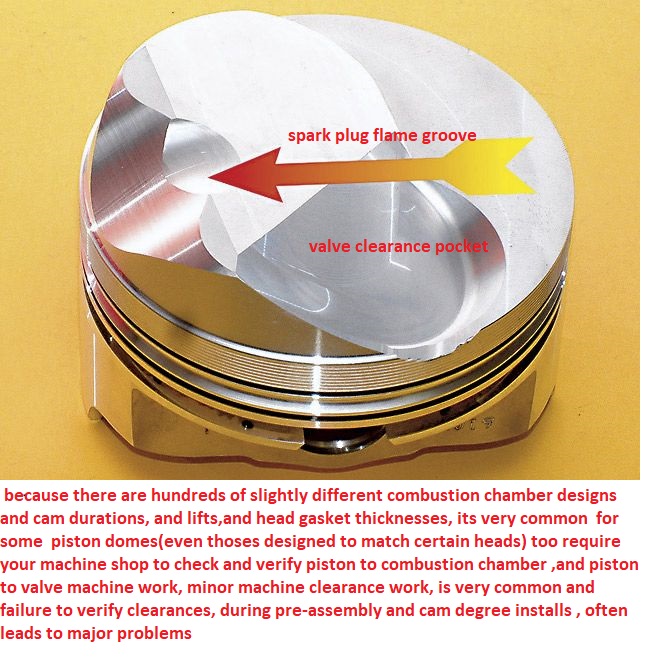

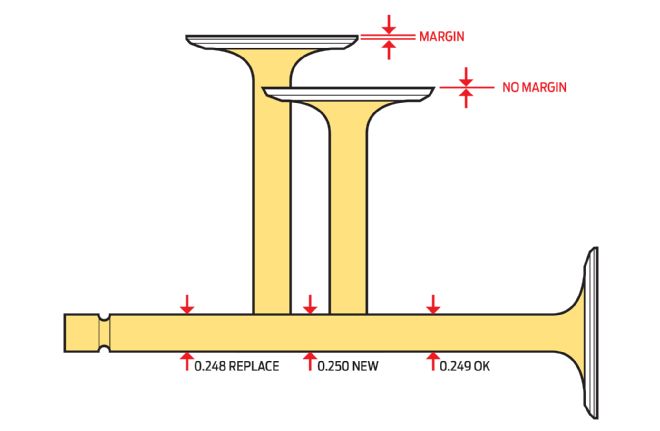

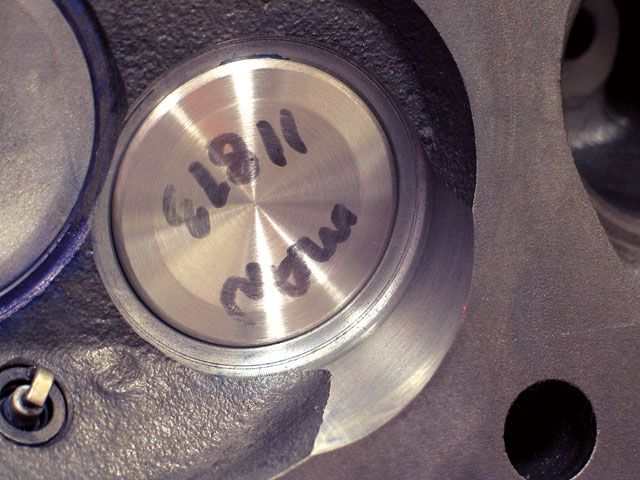

Any decent, experienced machine shop can measure your cylinder heads combustion chamber,

and calculate the required clearances after measuring your heads combustion chamber, and then do the correct machine work on your piston domes,

machining the domes for adequate,spark plug,clearance,

this is a very common issue and easily resolved,

Any decent, experienced machine shop can measure your cylinder heads combustion chamber,

and calculate the required clearances after measuring your heads combustion chamber, and then do the correct machine work on your piston domes,

machining the domes for adequate,spark plug,clearance,

this is a very common issue and easily resolved,

and it seldom costs much to have done.

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

http://garage.grumpysperformance.com/index.php?threads/more-port-flow-related-info.322/

http://garage.grumpysperformance.co...2-bbc-rebuild-but-think-things-through.13604/

http://garage.grumpysperformance.co...t-intake-on-oval-port-heads.13146/#post-69975

USE THE CALCULATORS, YOULL, QUICKLY FIND THE LIMITATIONS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.users.interport.net/s/r/srweiss/tablehdc.htm

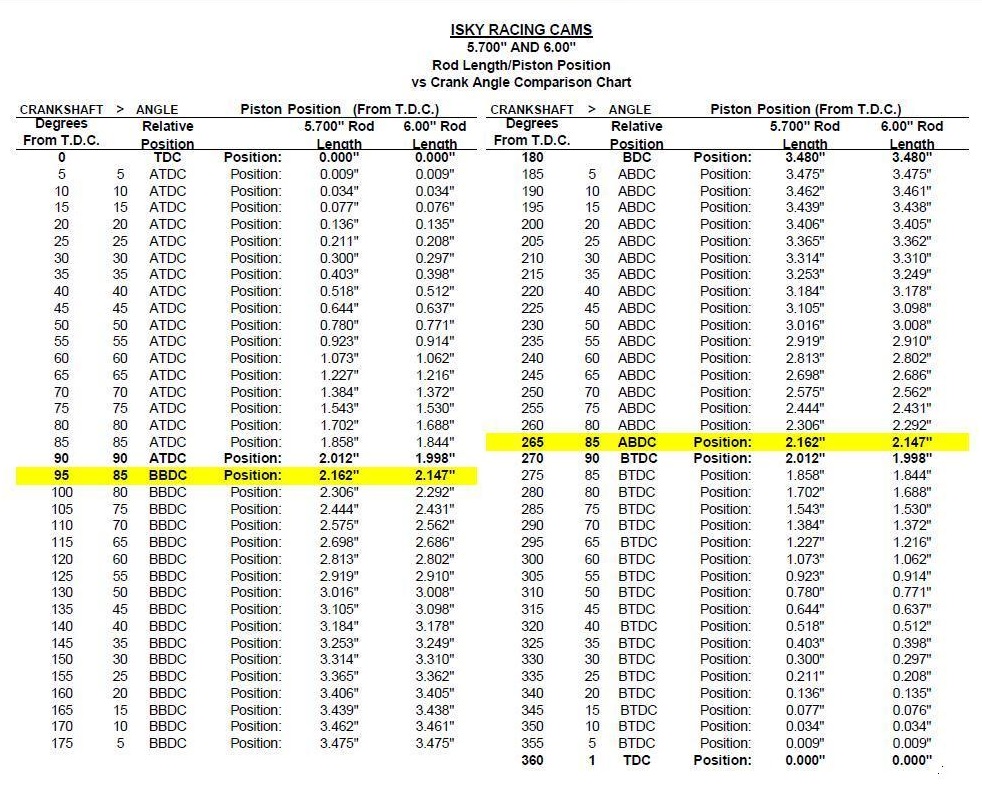

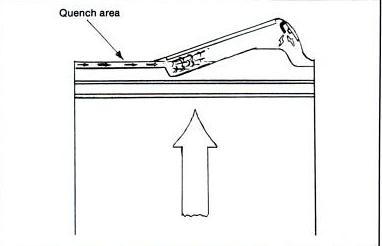

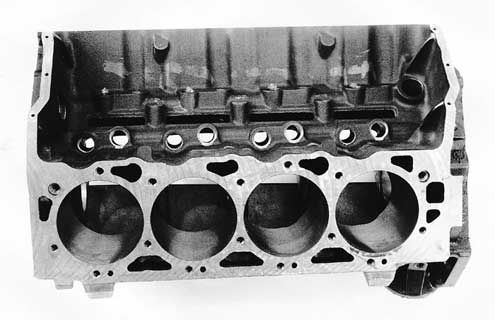

it should be rather obvious that youll need to know the exact distance the piston deck sits at TDC ,above or below the block deck surface and the valve notch recess or pop-up dome volume of the piston to do accurate quench or compression calculations

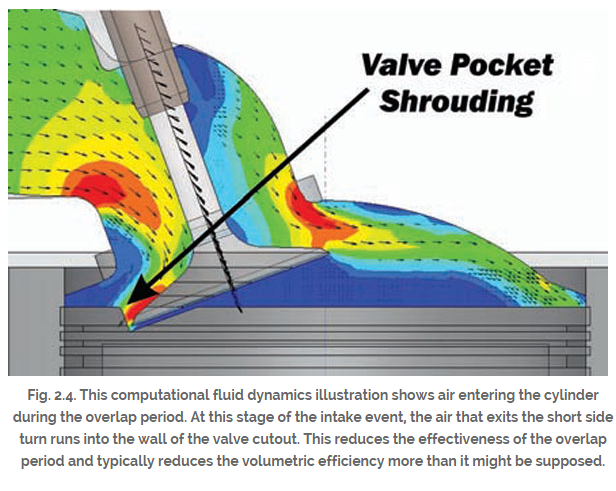

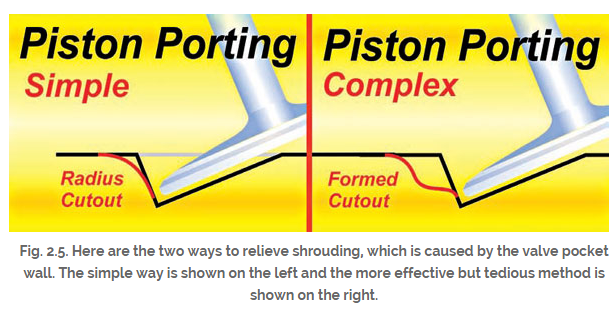

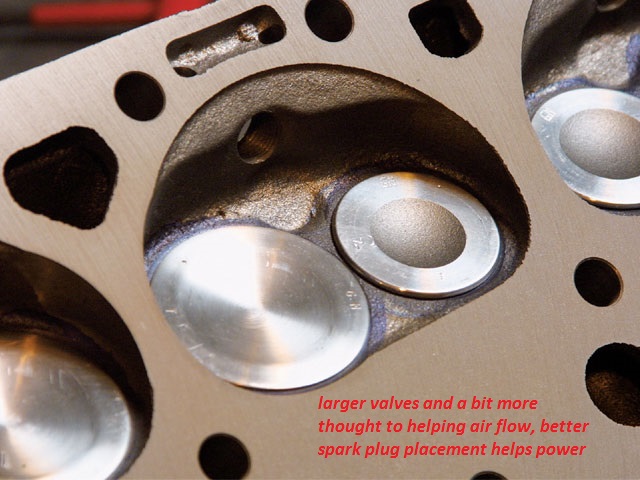

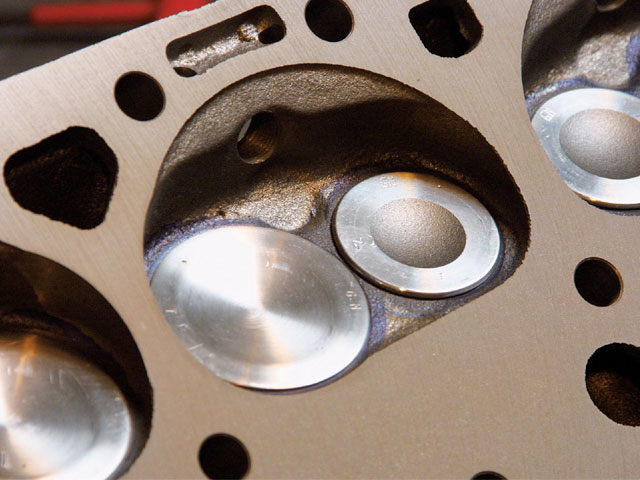

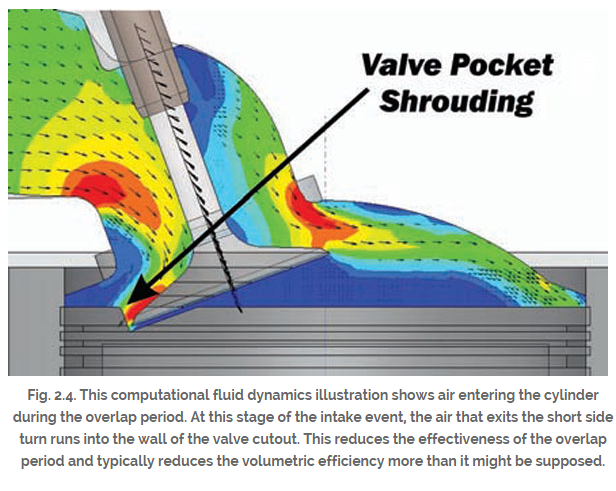

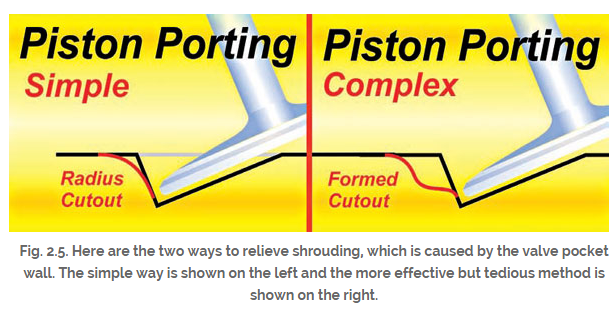

keep in mind any valve clearance recessed areas must have the areas shrouding flow blended to increase rather than restrict air flow and to reduce the potential for detonation that sharp exposed edges tend to have

viewtopic.php?f=27&t=1831&p=4763#p4763

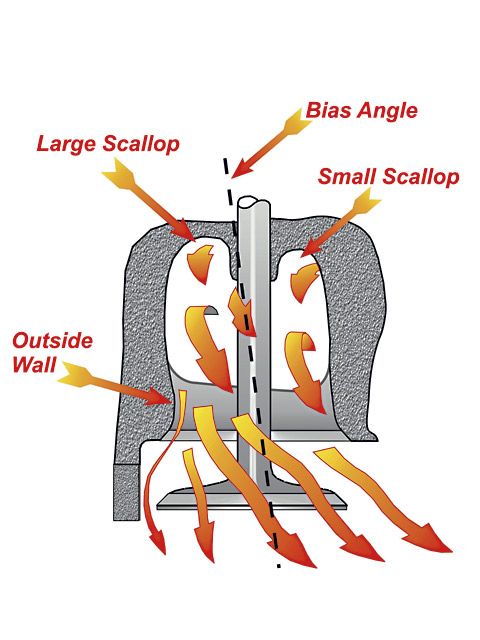

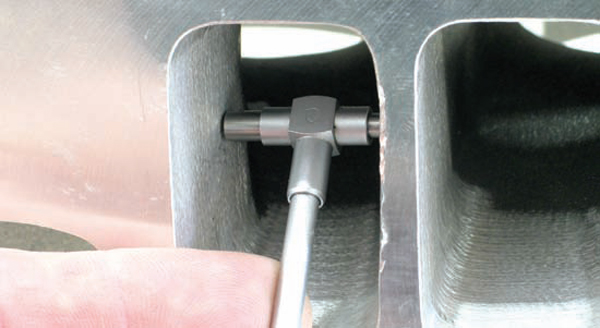

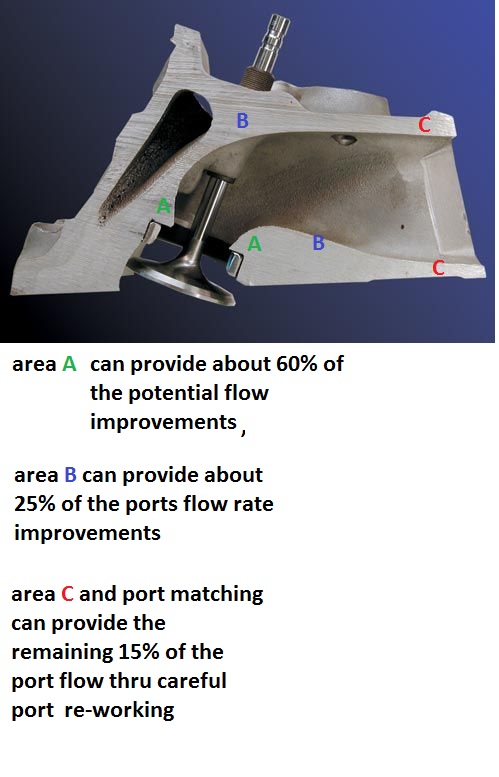

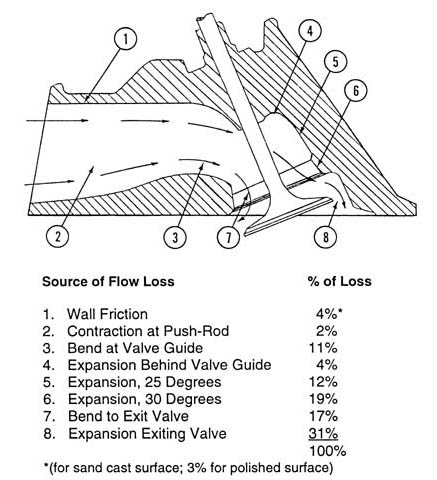

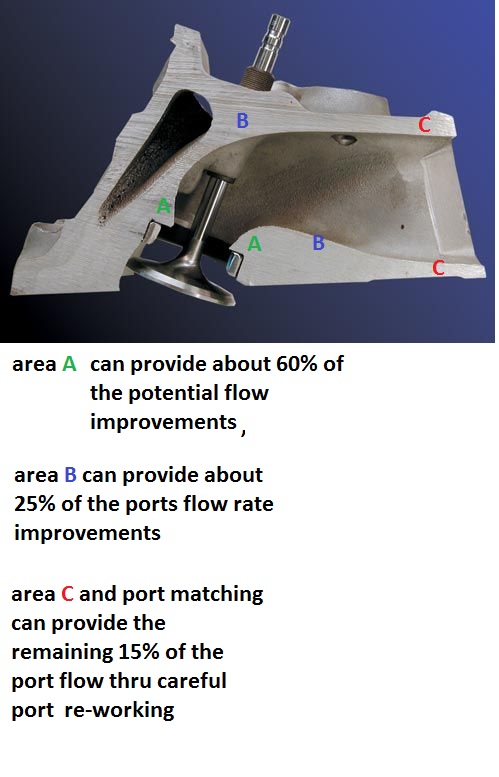

notice how the valve seat supporting casting in the cylinder head, throat extends out into the port and restricts the valve flow, a critical area that port and bowl clean -up can usually gain significant flow improvements

horsepower is a mathematical expression of how effectively you can use TORQUE or the rotational force an engine produces

torque x rpm/5252=HP

torque is the basic result of, the efficient use of,

your engines DISPLACEMENT and COMPRESSION, ratio and the fuels octane limitations, as your effective pressure above the piston is the result of both the volume of fuel/air mix being burnt and how efficiently that burnt fuel, can produce cylinder pressure.

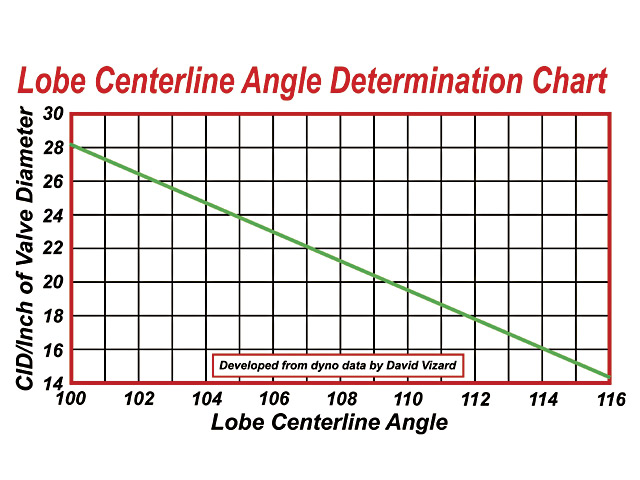

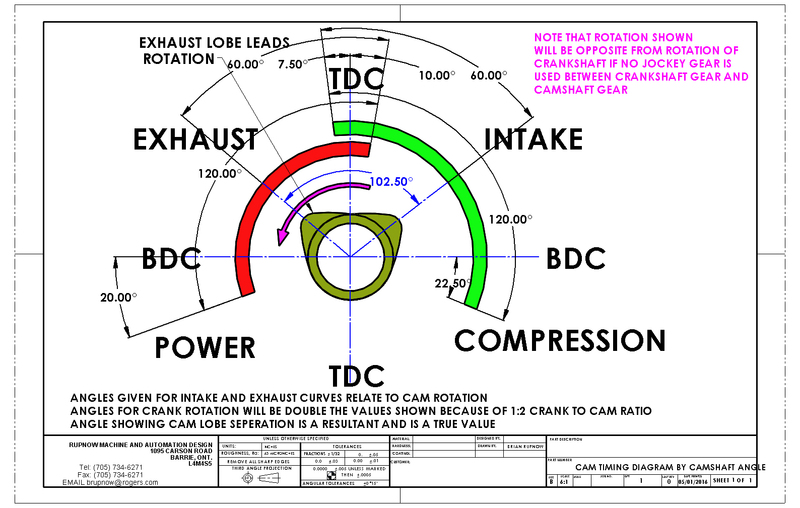

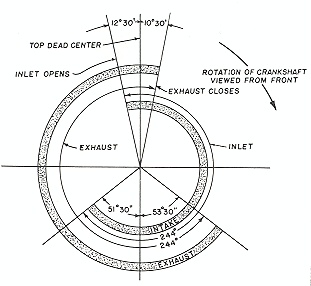

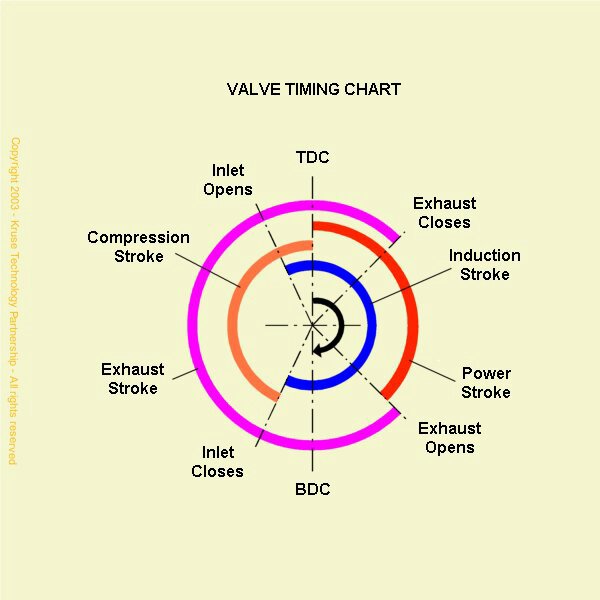

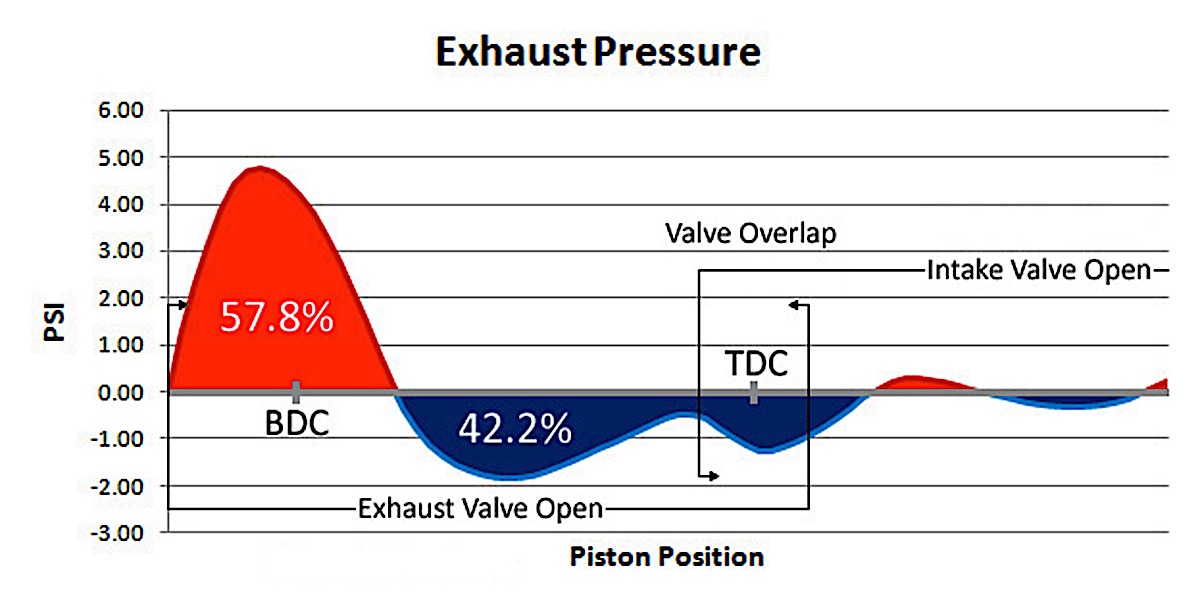

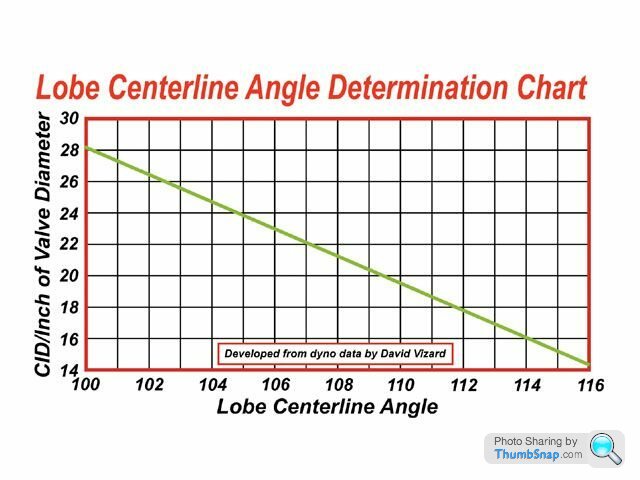

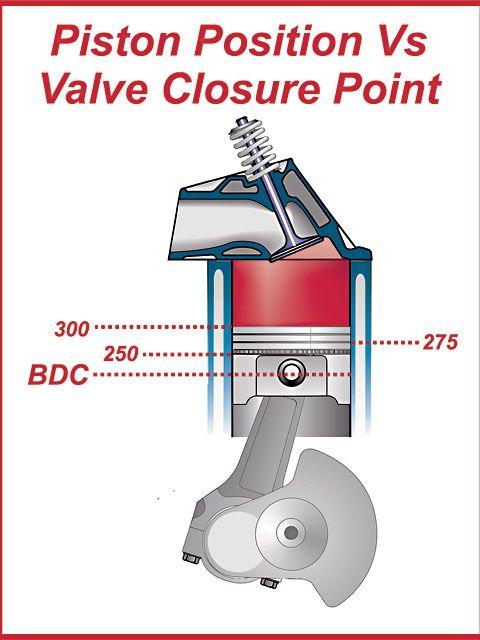

changing the cam timing and duration will change both the rpm range and that cylinder fill efficiency at any specific rpm.

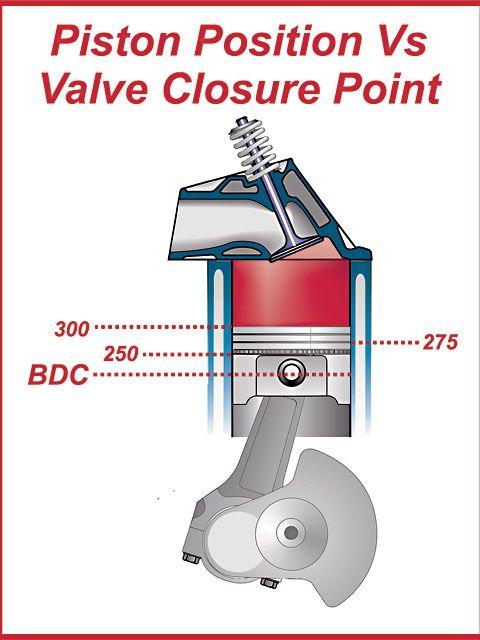

the cam timing obviously effects both the cylinder filling efficiency and port flow and obviously increase lift and longer duration allows more potential flow, but a bit less volume trapped above the moving piston, as it can,t compress anything until both valves seat

READ LINK

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...-pushrods-and-check-info-you-might-need.5931/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/

you can,t guess or assume, a stock push rod length will work, especially if you used an aftermarket, cam, lifters or rockers or changed cylinder heads ,you,ve got to measure correctly and get the correct length, failure to take the time and effort required usually results in valve train durability issues or engine damage, yeah you can ignore the info provided, but taking the time to do it correctly will save you a whole lot of potential problems & grief later on.

http://www.circletrack.com/enginetech/1 ... ch_engine/

http://www.gofastnews.com/board/technic ... uding.html

http://www.hotrod.com/how-to/engine/061 ... d-porting/

http://www.motortecmagazine.net/article.asp?AID=30&AP=1

http://www.eurospares.com/graphics/engi ... 0Time!.pdf

http://www.gofastnews.com/showthread.ph ... rt-Volumes

http://www.eastwood.com/engine-port...er&utm_medium=Merchant-Centre&SRCCODE=1SE1530

http://www.rbracing-rsr.com/runnertorquecalc.html

viewtopic.php?f=52&t=8460&p=29682&hilit=curtain+flow+angle#p29682

http://users.erols.com/srweiss/tablehdc ... _Big_Block

http://www.j-performance.com/index.php? ... view&id=48

http://www.cfmperformance.com/cfmproducts/flowbenches

http://racingsecrets.com/speedtalk_head_porting.shtml

http://www.diyporting.com/Shrouding.html

viewtopic.php?f=27&t=3379&p=8922&hilit=+shop+filter#p8922

viewtopic.php?f=50&t=3422

http://www.circletrack.com/enginetech/c ... index.html

http://victorylibrary.com/mopar/chamber-tech.htm

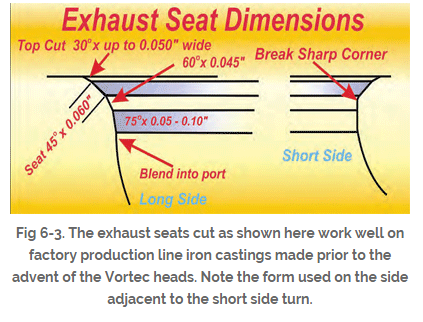

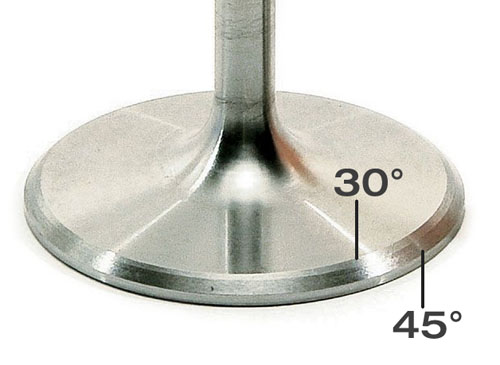

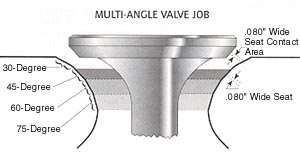

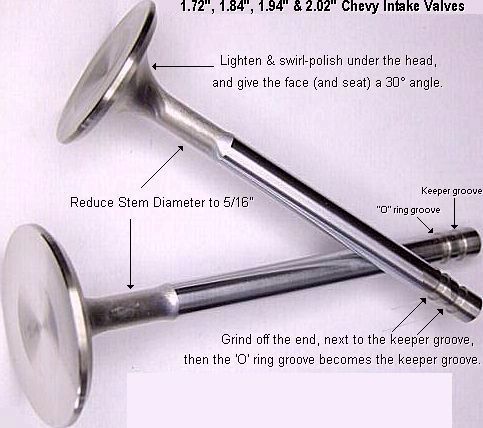

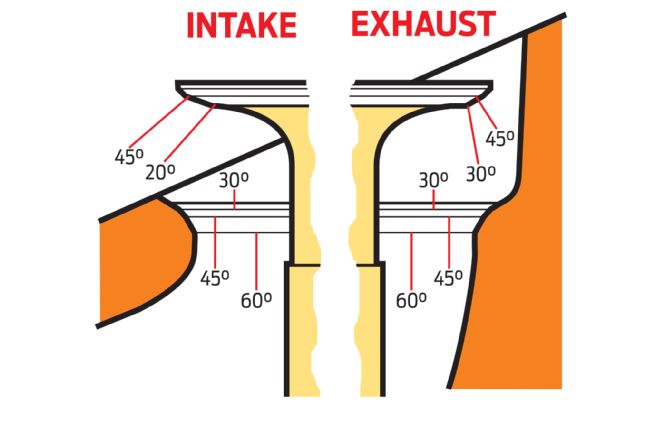

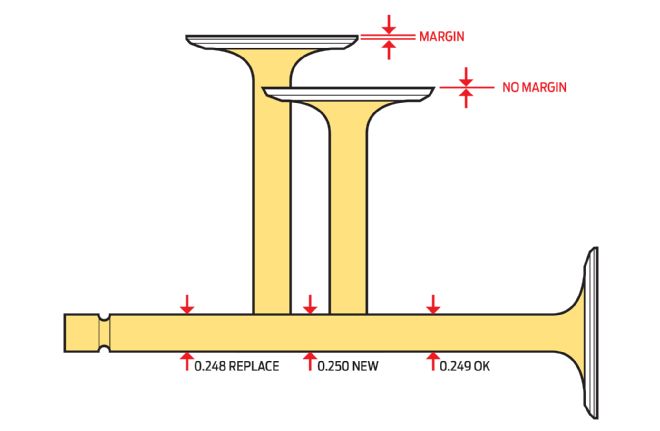

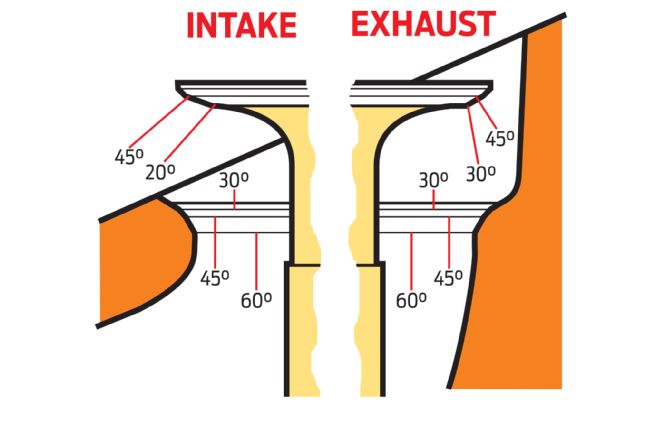

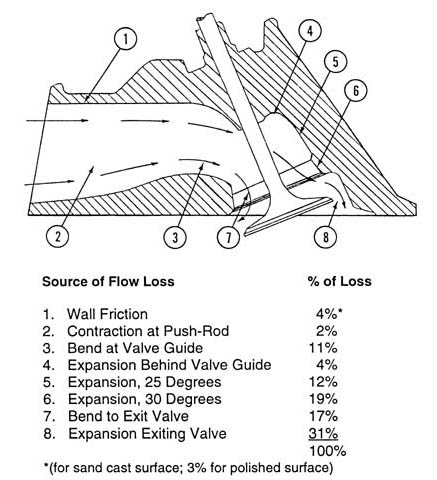

valve seat and back face angles ,valve diameter and valve lift and duration effect the flow thru the curtain area

keep in mind that valve may be forced off its seat, too full lift and re-seating 50 plus TIMES A SECOND at near 5500 rpm, so theres very little TIME for gases to move through the very restrictive space between the valve seat and valve edge

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

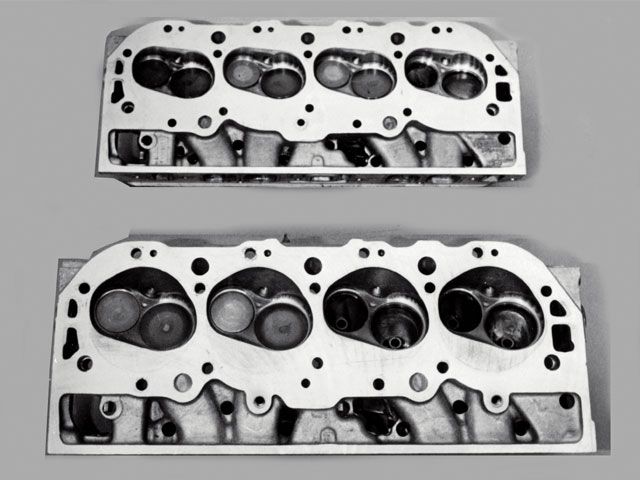

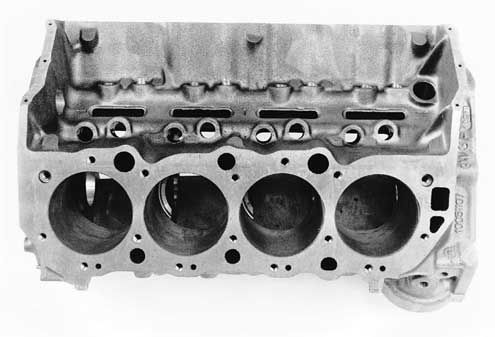

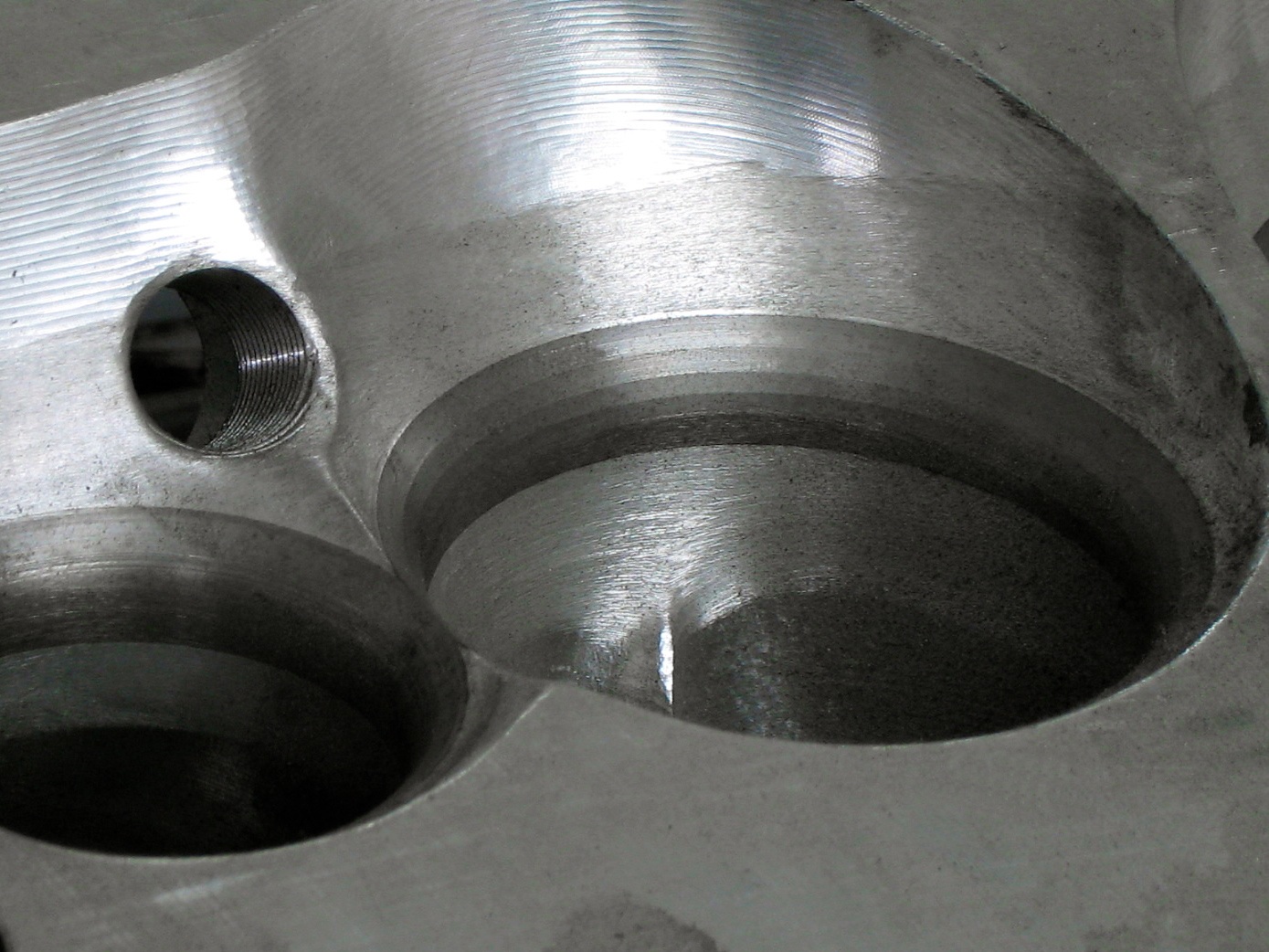

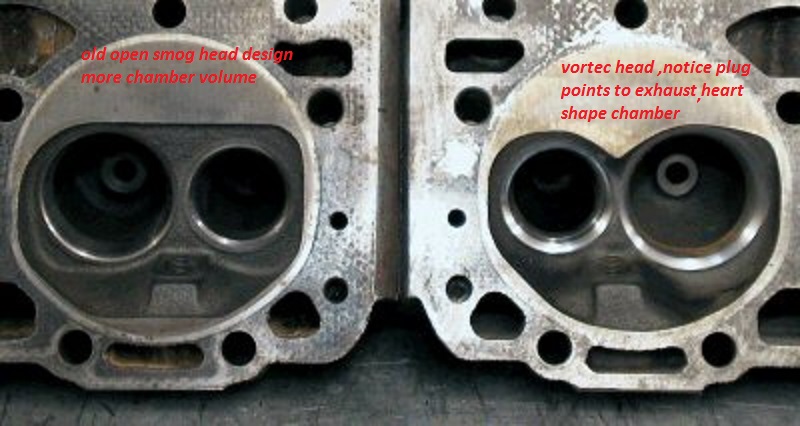

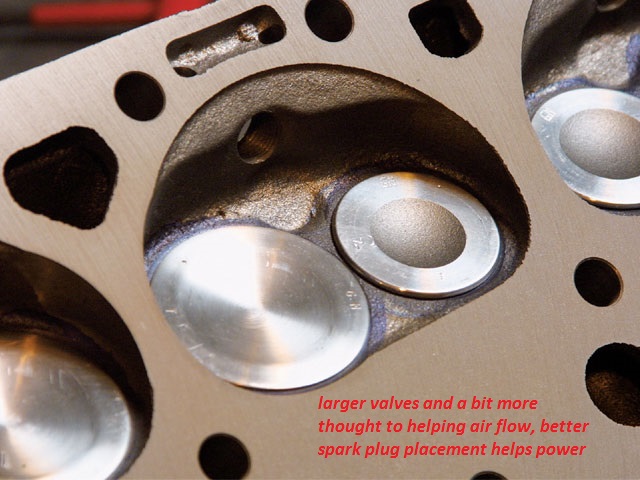

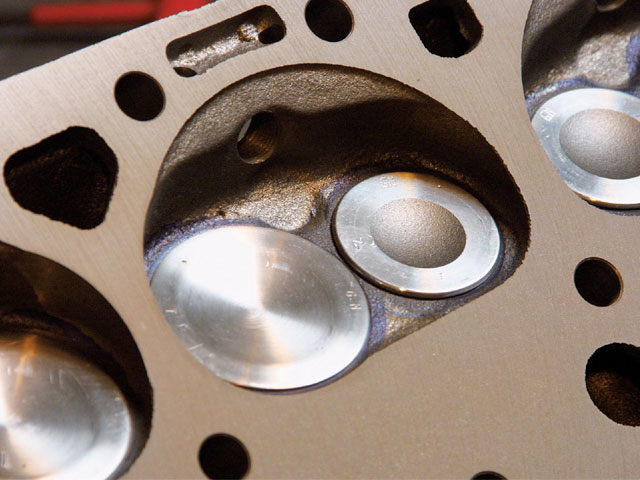

restrictive, as cast

less restrictive after unshrouding the valve

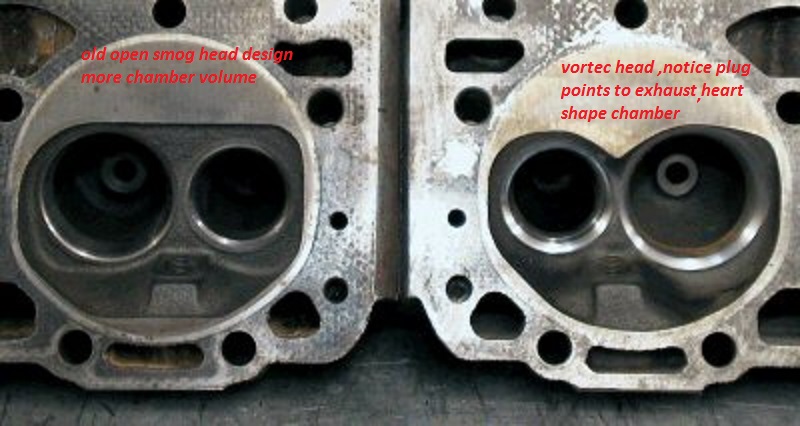

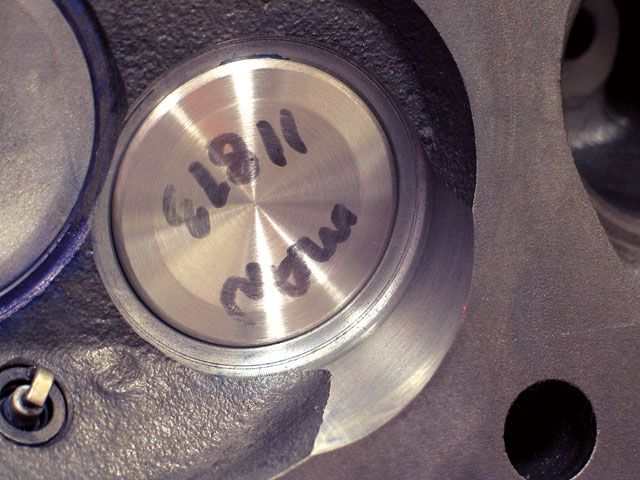

notice the tight bath tube shape and shrouded valves but decent quench areas in the fuelie head above

smog era heads like the #416 or #624 that came on the 1984 corvettes were less closed , because of the laid back chamber wall but they were designed for lower compression low octane fuels not performance

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

SO HOW MUCH WOULD YOU LIKELY GAIN FROM A HEAD SWAP THAT ALLOWED YOUR HEAD FLOW ON A SERIOUS BIG BLOCK TO JUMP FROM LETS SAY 370CFM to lets say 425CFM?

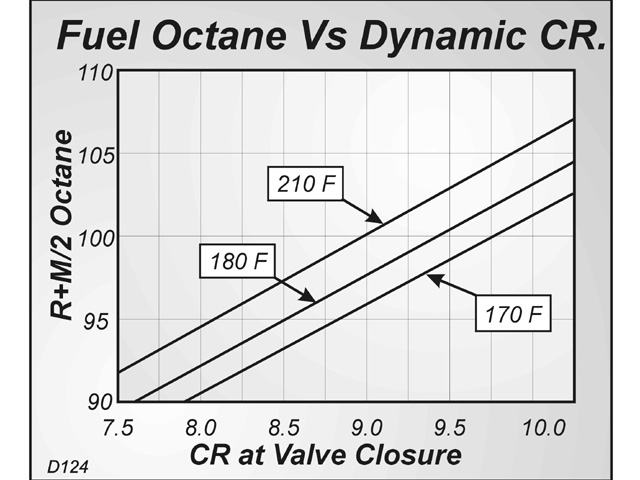

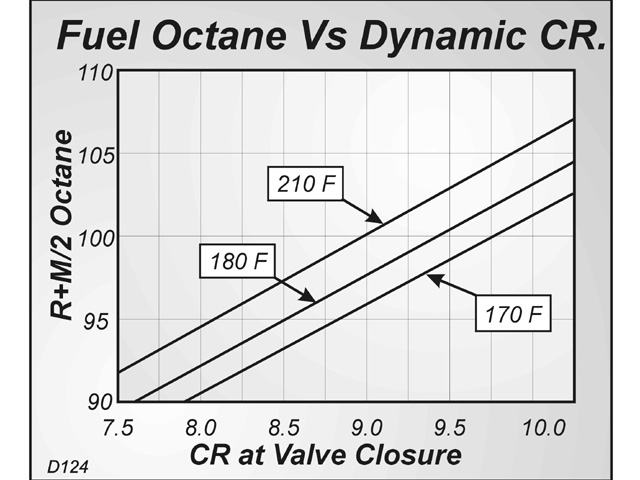

Every factor has some effect on the total combo, polish the combustion chamber and round all sharp edges and get the quench correct and use aluminum cylinder heads and you can run a bit more compression than stock iron heads , run a richer FUEL/AIR mix and a bit slower ignition advance curve and you can run the same total ignition advance on the same engine with out getting into detonation nearly as easily, run a 4.11:1 rear gear and a larger aluminum radiator with a 180F t-stat and theres obviously other factors, heat range on the spark plugs, and you can use a system that sprays E85 only under higher loads if you want to run a separate fuel tank , etc. so theres no 100% set compression to octane rules.

but generally the higher the combustion chamber temps, the higher the air temps, the higher the engine coolant temps and oil temps and the higher the compression,the faster the ignition advance, the MORE likely youll experience detonation under high engine loads

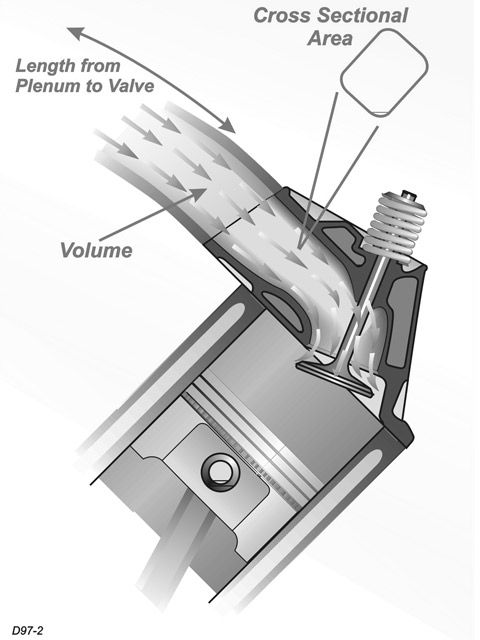

ITS A COMMON MISCONCEPTION,THAT YOU MEASURE PORT CROSS SECTION AT THE PORT ENTRANCE,BUT ITS NOT the port area at the entrance , you need to use in the calcs, ITS the MINIMAL port cross section at the SMALLEST point in the port, usually near the push rod area.

LIKE a funnel, its not the largest part of the opening but the smallest thats the restriction to flow

heres some old fuelie heads with the chamber slightly un-shrouding the intake valve pocket walls

polishing the combustion chambers and smoothing contours tends to reduce detonation and improve power, combine that with port and bowl area clean-up and careful blending of the port walls. and a back cut on valves with a multi angle valve job, etc. and its not unusually to gain 25-40 hp or more, from port work and combustion chamber mods that improve air flow rates

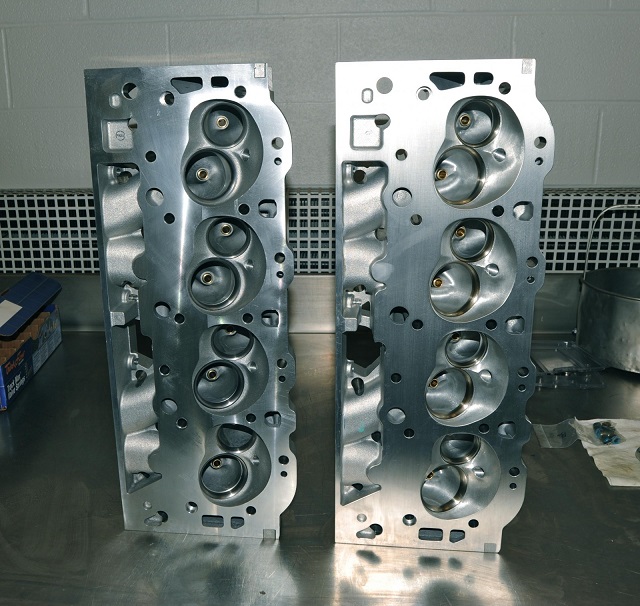

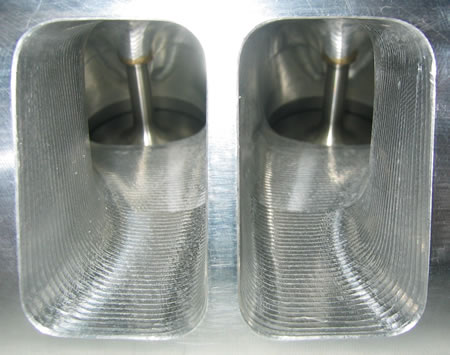

BTW HERES SOME REWORKED BIG BLOCK HEAD COMBUSTION CHAMBERS, TO UN-SHROUD THE VALVES, SMOOTH THE COMBUSTION CHAMBERS

STOCK

SIGNIFICANTLY IMPROVED FLOW

RELATED INFO

viewtopic.php?f=52&t=148&p=182#p182

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

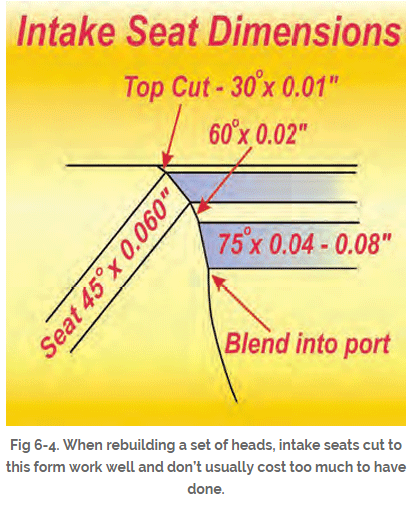

obviously a bit of port, runner and bowl clean-up port work , gasket matching and valve pocket clean-up along with a well machined 3 or 5 angle valve job ,would go a long way to potentially improving the total flow numbers

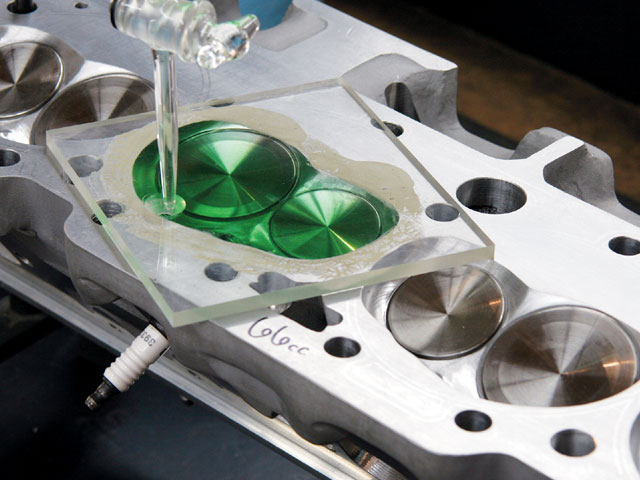

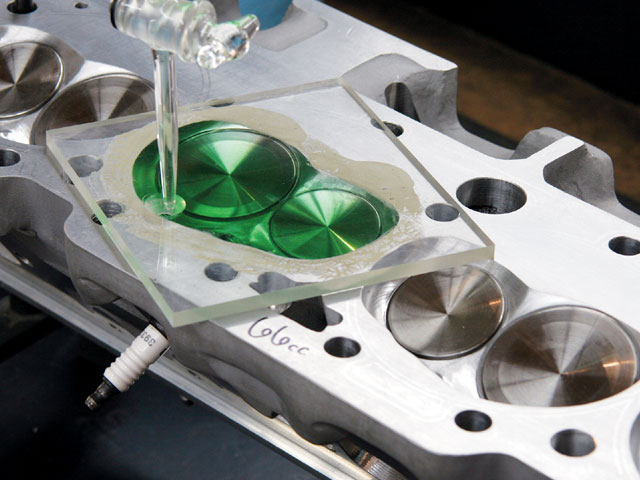

yes cc ing the chambers and getting the quench right helps a great deal

http://garage.grumpysperformance.co...r-head-porting-tools-abrasives-sources.10683/

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-60554

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0209-chevy-gm-cylinder-heads/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

head gaskets are rarely completely round, nore are combustion chambers

you,ll want to place a head gasket you,ll use on the heads and mark the area inside the opening as the only areas you can change,

(notice the gasket fire ring is NOT a perfect circle like many people assume)

ideally you,ll want to un-shroud the valves while opening up the combustion chamber volume, but not extend the combustion chamber past the front edge of the gasket fire ring as that usually causes gasket failure

cc your cylinder heads, combustion chamber, or piston dome , or port volume

CC'ing a cylinder head is a process that measures the volume of the combustion chambers in the cylinder head. The term CC'ing is referring too the cubic centimeters of the pocket (combustion chamber). the purpose of cc'ing the head is to determine the size of the combustion chambers so they can...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/can-t-find-matching-pistons.14206/

http://garage.grumpysperformance.com/index.php?threads/piston-related-info.110/

http://garage.grumpysperformance.co...u-thinking-about-your-potential-combos.14607/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-31684

http://www.superchevy.com/how-to/89678-valve-angles/

http://www.enginebuildermag.com/200...ts-what-you-need-to-know-to-go-with-the-flow/

http://johnmaherracing.com/tech-talk/3-angle-valve-job/

http://garage.grumpysperformance.co...chevy-cams-and-a-few-similar-aftermarket.133/

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-60554

READ THRU THIS LINK

you might have somehow gotten the IN-CORRECT idea that the valve center-line and CYLINDER center-line are exactly matched in a sbc, they are NOT!

plus the valves are angled at a 23 degree angle so the outer valve edges close to the cylinder walls do not drop strait down into the bore as the valves open at the point of the cylinders largest diam. moving the head center-line to move the valve center- line to maximize flow at max valve lift potentially helps performance.

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

the most common mistake made by many people is that they fail to look at an engine as an interconnected group of component sub systems and they don,t realize that changes to a single component, no mater how much potential that component has is not going to allow that component or change in the potential to be realized until all the matched and supporting systems have similar potential.

EXAMPLE ,

the heads may be capable of flowing (x) on a stock engine but with careful selection of a cam with the correct duration and lift, and with a tuned header, and matching valve train mods along with some port and bowl clean-up the resulting improvements can be significantly more impressive.

Any decent, experienced machine shop can measure your cylinder heads combustion chamber,

and calculate the required clearances after measuring your heads combustion chamber, and then do the correct machine work on your piston domes,

machining the domes for adequate,spark plug,clearance,

this is a very common issue and easily resolved,

Any decent, experienced machine shop can measure your cylinder heads combustion chamber,

and calculate the required clearances after measuring your heads combustion chamber, and then do the correct machine work on your piston domes,

machining the domes for adequate,spark plug,clearance,

this is a very common issue and easily resolved,

and it seldom costs much to have done.

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

http://garage.grumpysperformance.com/index.php?threads/more-port-flow-related-info.322/

http://garage.grumpysperformance.co...2-bbc-rebuild-but-think-things-through.13604/

http://garage.grumpysperformance.co...t-intake-on-oval-port-heads.13146/#post-69975

USE THE CALCULATORS, YOULL, QUICKLY FIND THE LIMITATIONS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.users.interport.net/s/r/srweiss/tablehdc.htm

it should be rather obvious that youll need to know the exact distance the piston deck sits at TDC ,above or below the block deck surface and the valve notch recess or pop-up dome volume of the piston to do accurate quench or compression calculations

keep in mind any valve clearance recessed areas must have the areas shrouding flow blended to increase rather than restrict air flow and to reduce the potential for detonation that sharp exposed edges tend to have

viewtopic.php?f=27&t=1831&p=4763#p4763

notice how the valve seat supporting casting in the cylinder head, throat extends out into the port and restricts the valve flow, a critical area that port and bowl clean -up can usually gain significant flow improvements

horsepower is a mathematical expression of how effectively you can use TORQUE or the rotational force an engine produces

torque x rpm/5252=HP

torque is the basic result of, the efficient use of,

your engines DISPLACEMENT and COMPRESSION, ratio and the fuels octane limitations, as your effective pressure above the piston is the result of both the volume of fuel/air mix being burnt and how efficiently that burnt fuel, can produce cylinder pressure.

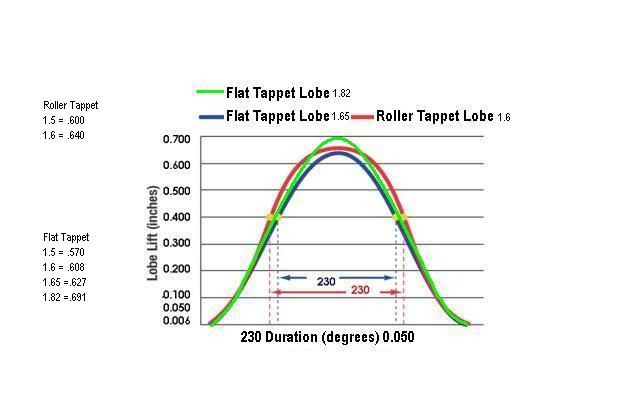

changing the cam timing and duration will change both the rpm range and that cylinder fill efficiency at any specific rpm.

the cam timing obviously effects both the cylinder filling efficiency and port flow and obviously increase lift and longer duration allows more potential flow, but a bit less volume trapped above the moving piston, as it can,t compress anything until both valves seat

READ LINK

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...-pushrods-and-check-info-you-might-need.5931/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/

you can,t guess or assume, a stock push rod length will work, especially if you used an aftermarket, cam, lifters or rockers or changed cylinder heads ,you,ve got to measure correctly and get the correct length, failure to take the time and effort required usually results in valve train durability issues or engine damage, yeah you can ignore the info provided, but taking the time to do it correctly will save you a whole lot of potential problems & grief later on.

http://www.circletrack.com/enginetech/1 ... ch_engine/

http://www.gofastnews.com/board/technic ... uding.html

http://www.hotrod.com/how-to/engine/061 ... d-porting/

http://www.motortecmagazine.net/article.asp?AID=30&AP=1

http://www.eurospares.com/graphics/engi ... 0Time!.pdf

http://www.gofastnews.com/showthread.ph ... rt-Volumes

http://www.eastwood.com/engine-port...er&utm_medium=Merchant-Centre&SRCCODE=1SE1530

http://www.rbracing-rsr.com/runnertorquecalc.html

viewtopic.php?f=52&t=8460&p=29682&hilit=curtain+flow+angle#p29682

http://users.erols.com/srweiss/tablehdc ... _Big_Block

http://www.j-performance.com/index.php? ... view&id=48

http://www.cfmperformance.com/cfmproducts/flowbenches

http://racingsecrets.com/speedtalk_head_porting.shtml

http://www.diyporting.com/Shrouding.html

viewtopic.php?f=27&t=3379&p=8922&hilit=+shop+filter#p8922

viewtopic.php?f=50&t=3422

http://www.circletrack.com/enginetech/c ... index.html

http://victorylibrary.com/mopar/chamber-tech.htm

valve seat and back face angles ,valve diameter and valve lift and duration effect the flow thru the curtain area

keep in mind that valve may be forced off its seat, too full lift and re-seating 50 plus TIMES A SECOND at near 5500 rpm, so theres very little TIME for gases to move through the very restrictive space between the valve seat and valve edge

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

restrictive, as cast

less restrictive after unshrouding the valve

notice the tight bath tube shape and shrouded valves but decent quench areas in the fuelie head above

smog era heads like the #416 or #624 that came on the 1984 corvettes were less closed , because of the laid back chamber wall but they were designed for lower compression low octane fuels not performance

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

SO HOW MUCH WOULD YOU LIKELY GAIN FROM A HEAD SWAP THAT ALLOWED YOUR HEAD FLOW ON A SERIOUS BIG BLOCK TO JUMP FROM LETS SAY 370CFM to lets say 425CFM?

Every factor has some effect on the total combo, polish the combustion chamber and round all sharp edges and get the quench correct and use aluminum cylinder heads and you can run a bit more compression than stock iron heads , run a richer FUEL/AIR mix and a bit slower ignition advance curve and you can run the same total ignition advance on the same engine with out getting into detonation nearly as easily, run a 4.11:1 rear gear and a larger aluminum radiator with a 180F t-stat and theres obviously other factors, heat range on the spark plugs, and you can use a system that sprays E85 only under higher loads if you want to run a separate fuel tank , etc. so theres no 100% set compression to octane rules.

but generally the higher the combustion chamber temps, the higher the air temps, the higher the engine coolant temps and oil temps and the higher the compression,the faster the ignition advance, the MORE likely youll experience detonation under high engine loads

A HARD number that has held pretty true for conventional BBC on gasoline , with compression ratios up ner optimum, near 12:1-13.5:1 to predict peak HP from head flow is .25-.27 x intake flow rate @ 28" x 8 (# of cyls). Like others have said, a lot of variables,like efficiency of exhaust scavenging,compression ratio and valve lift VS port potential flow, but it has been within 20 or 30 HP on several different BBC's I've seen being dynoed.

For example, I had an 357 AFR-headed 540, the heads flow 425cfm @ 28". So 425 x .27 x 8 = 918 HP. It made 940. Another motor calc'd at 1030, made 1040 on the dyno.

Using the same logic, 50 cfm x .27 x 8 = 108 hp. It's not that simple, it depends on combination, how optimized everything is etc. But if you are looking for round numbers, 50-75 hp is probably realistic, 100 hp possible

ITS A COMMON MISCONCEPTION,THAT YOU MEASURE PORT CROSS SECTION AT THE PORT ENTRANCE,BUT ITS NOT the port area at the entrance , you need to use in the calcs, ITS the MINIMAL port cross section at the SMALLEST point in the port, usually near the push rod area.

LIKE a funnel, its not the largest part of the opening but the smallest thats the restriction to flow

heres some old fuelie heads with the chamber slightly un-shrouding the intake valve pocket walls

polishing the combustion chambers and smoothing contours tends to reduce detonation and improve power, combine that with port and bowl area clean-up and careful blending of the port walls. and a back cut on valves with a multi angle valve job, etc. and its not unusually to gain 25-40 hp or more, from port work and combustion chamber mods that improve air flow rates

BTW HERES SOME REWORKED BIG BLOCK HEAD COMBUSTION CHAMBERS, TO UN-SHROUD THE VALVES, SMOOTH THE COMBUSTION CHAMBERS

STOCK

SIGNIFICANTLY IMPROVED FLOW

RELATED INFO

viewtopic.php?f=52&t=148&p=182#p182

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

obviously a bit of port, runner and bowl clean-up port work , gasket matching and valve pocket clean-up along with a well machined 3 or 5 angle valve job ,would go a long way to potentially improving the total flow numbers

yes cc ing the chambers and getting the quench right helps a great deal

http://garage.grumpysperformance.co...r-head-porting-tools-abrasives-sources.10683/

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-60554

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0209-chevy-gm-cylinder-heads/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

Last edited by a moderator: