heres a rather interesting article about the potential performance upgrades a stock set of OVAL PORT CAST IRON O.E.M BBC heads can produce with careful work.

but before you get the idea that spending a great deal of time cash and effort on porting stock cylinder heads is a great option, Id have to point out that theres dozens of aftermarket aluminum performance cylinder heads available with bigger valves, better port designs and far better air flow potential than any port work on the stock cast iron heads could ever provide.

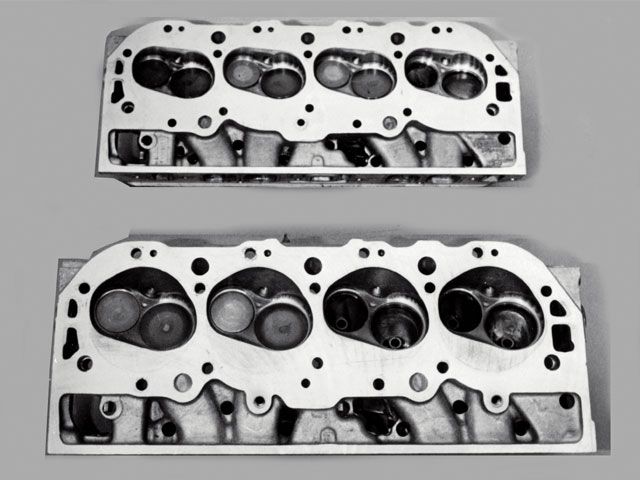

the upper closed chamber head is bath tube shaped to provide dual opposed quench areas that squish against the piston deck,

forcing the fuel air mix toward the central cylinder bore, the lower open chamber head combustion chamber was found to un-shroud the valves,\

thus increasing the cylinder fill efficiency especially at upper rpms.

the dome higher compression ratio pistons for both combustion chambers are similar in shape to the combustion chambers they are designed too be used with.

the closed chamber piston can be used with the larger open chamber combustion chamber , but its reduced volume results in less effective compression and the dome,

of the closed chamber dome is marginally restrictive to the flame front propagation.

other related threads (don,t skip reading the sub linked info)

http://garage.grumpysperformance.co...eresting-option-for-bbc-efi.14424/#post-74413

http://garage.grumpysperformance.co...-head-build-iron-headed-rat.14283/#post-72904

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/

http://garage.grumpysperformance.com/index.php?threads/aluminum-heads-polishing-and-porosity.14689/

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29719

http://garage.grumpysperformance.com/index.php?threads/big-block-head-comparison.319/

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/#post-72463

http://garage.grumpysperformance.co...ld-but-think-things-through.13604/#post-70242

http://garage.grumpysperformance.com/index.php?threads/aftermarket-heads-for-a-bbc.12316/#post-71999

http://garage.grumpysperformance.co...t-intake-on-oval-port-heads.13146/#post-71777

http://garage.grumpysperformance.com/index.php?threads/cnc-port-work-related.15313/

http://garage.grumpysperformance.com/index.php?threads/stock-gm-push-rod-length.3844/#post-70588

http://garage.grumpysperformance.co...asonably-fast-in-street-trim.3404/#post-69122

http://garage.grumpysperformance.com/index.php?threads/bbc-intake-manifold-choices.12949/#post-67671

http://garage.grumpysperformance.co...a-pump-gas-bbc-combo-can-do.12330/#post-60896

Polishing a Set of Sneakers

http://www.maliburacing.com/patrick_budd_article.htm

Patrick Budd - Budd Performance

NSCA Competition Director

Photo courtesy of Michael Ray

a general list of components commonly found in such an engine:

and yes generally all parts selected should match the intended application's

operational rpm and power range as should the drive trains gearing

- Engine block (and main caps and bolts)

- Cylinder heads(head gaskets and bolts)

- rocker stud girdle

- Crankshaft

- damper and bolt

- flexplate and/or flywheel

- Pistons

- rings for pistons (compression, second and oil rings)

- piston connecting rod pins

- cylinder head index dowels

- timing cover index dowels

- crank keyway

- oil filter

- oil pressure sensor

- crankshaft pilot bearing

- intake manifold thermostat

- block oil pressure sensor

- Connecting rods(including bolts)

- bearings (crank and rod)

- oil pump( plus mounting bolt)

- oil pump pick-up (remember to braze)

- BRASS freeze plugs (use sealant)

- oil passage plugs

- Camshaft (security plate and bolts)

- lifters

- push rods

- gaskets

- crank damper

- crank damper, washer and bolt

- timing chain

- timing chain set with cam and crank gears

- timing chain cover

- flexplate

- flex plate bolts

- pushrod guide plates

- rocker arms

- rocker arm adjustment nuts

- rocker arm studs

- valve covers

- valve cover bolts

- Valvetrain components (valves,spring shims, valve seals, springs,valve keepers,spring retainers)

- Intake manifold (gaskets and bolts)

- Exhaust headers (gaskets and bolts)

- Oil pan(gaskets and bolts)

- windage tray

- Water pump(gaskets and bolts)

- ignition wire and (ceramic spark plug boots)

- Spark plugs

- Fuel injectors

- Ignition system components

Not long ago there was an article in one of the car mags about what it takes to build and maintain a ten-second street and strip car. The article made it sound like getting a ‘real’ street car into the tens was akin to splitting atoms, and a bank heist would be required to fund the operation. Well, I can promise you it isn’t so, and I’ll detail two similar, yet different examples to back it up. The average home assembler can build either engine for far less than $5000 from carburetor to oilpan. Heck, one of these tanks goes 9’s, so it can’t be all that hard.

Money and car crafting have long gone hand in hand, and the crafter with the most of it tends to win the most trophies. Brains, however, especially the kind I call ‘woodchuck engineering’ can be the great equalizer. Tuning, the patient one change at a time variety, can transform a lazy also ran to the kind of car that leaves you scratching your head asking, “what does this guy know”? So too can some extra thought placed into the combination and compatibility of the parts selected. I’ve often said that if racers spent half as much time researching the right part, instead of researching the cheapest price, they’d be much further ahead, both in terms of performance and budget. Before we go and get our ‘Woodchuck Phd.’ however, lets cover some of the real basics of street hero construction.

First of all, throw most of your pre conceptions of what makes a car streetable right out the window when you decide to go fast. All those weak-kneed vacuum secondary, dual planed induction systems need to be on your tow unit, not your Saturday night bruiser. All those handy-dandy cam charts that suggest paltry little lift and duration figures? They’re perfect for the birdcage. Torque does have it’s place, and it’s very important when we’re dealing with a heavy street legal car, but it needs to be higher in the rpm range than these suggested grinds will offer. We need torque at the shift recovery point, to accelerate the car off the bottom of the gear change. We can still have a reasonable idle, predictable brake feel, and good low end throttle response. We may not be able to fire up the air conditioner and lift the headlight doors while we pump the brakes, but we really want to go drag racing, not autocrossing, right? I also suggest a rather high compression ratio; and this is where I part company with many of the ‘purists’, that insist a street car must run pump gas. Well, since this build-up requires using heads that don’t have hardened seats, (they require leaded fuel to avoid seat recession) and it’s the compression that allows the use of more aggressive cam timing, (without murdering low speed torque) it’s the cheapest power adder we can use. Look at it this way- the average race gas costs 1.50 more per gallon than premium, and even if you burn up three 55 gallon drums a summer, that’s a $247.50 upcharge a year. We don’t even want to talk about how much it costs with trick parts to recover the lost power from high compression. We don’t need a roller, but solid lifter flat-tappet cams are a big help, and we’ll need a somewhat loose converter. Many of the better trans shops can now build you a piece that will ‘flash’ high while maintaining decent part throttle manners.

Both of the engines we are going to discuss here are garden variety, low buck, oval port Big Block Chevrolets, one a 468 inch open chamber engine and the other a 432 inch closed chamber mill we’ll use a bit of nitrous with. We’ll be discussing them together because most of the concepts and operations apply to both engines; I’ll specify where and why the buildups differ. The ideas we discuss here will cross over to most marques, so you Ford and Mopar guys don’t need to flip the page just yet.

My good friend Mike Nerwin has been a hardcore footbrake racer for as long as I can remember. He’d also been ‘the chased’ for equally as long, meaning he left first at the Saturday night brackets because he was fairly slow. Mike came to me last fall with a desire to go quicker, and faster, so he could keep the competition in his view a higher percentage of the time. He also wanted a package that had the necessary street manners to allow him to cruise it whenever he chose. Lee Martin is a die-hard street enthusiast that only goes to the track to see how quick he can go. He already owned a wounded 427, and his budget demanded we make good use of it. His 10” street tire Regal needs to be dead reliable while quick enough to part in the ‘front row’ of the local cruise night.

My first question, as it is with all customers, was how fast do they want to go? That question needs to be answered honestly, because you can’t build a 6000 square foot mansion on sand, as you can’t make 800 horsepower with 3/8 rods. My next question was how much money do you have? This has more to do with feeding the beast once it’s completed than it does the cost of the build-up. A finished car that’s too expensive to race or enjoy doesn’t do anyone any good. Third and last, I ask how skilled an assembler the customer is, because I may be able to give them an assembled shortblock and have them save money by completing the rest of the work themselves. Mike wanted to go high tens, and had a fairly short budget, although he understood the flexibility some compression allowed me so he’d buck up for ‘cheap’ race gas. He also has a tank for a car, 3600 lbs of second generation f-body. Since it’s virtually impossible to get him to lighten anything up, I knew I’d need around 600 horsepower and 550 ft/lbs. of torque to reach his target. Lee’s goals were a bit more modest without N20, but once he turned the bottle on, the wanted a solid nine second timeslip. He also has what amounts to a battleship, a 3500 lb. Regal. This meant we needed at least 550 horses before we engaged the spray. I again explained the added flexibility of race gas and how higher compression would make the package less peaky and easier to drive, and he agreed the added cost of fuel wasn’t a deterrent. I figured we could get him in the nines, and run a few high tens on horsepower, as well.

Within a week, I had a couple of cores cluttering up my garage. One was a cast crank, oval port 454 and the other a wounded, albeit complete, 427. The 454 was a two-bolt block, 781 headed smog era deluxe. Lee’s 427 core came with closed chamber heads, and a steel crank. He also had the right lowbuck intake, an un-ported Holley Strip Dominator. While it’s nice to be able to work with the latest aftermarket heads and the like, this project is about making do with what we have. We were definitely polishing a couple of sneakers, but that was part of the challenge. After dis-assembling everything, we found the 454 had a nice, straight, virgin crank and a .030 over block. The 427 wasn’t quite so lucky. It had a couple of cracked pistons, broken rings, and significant bore wear. It would require at least a .030 overbore to clean up the mess. After inspecting the head castings, I didn’t see any major flaws or cracks. They both had the typical seat recession, but they were receiving 2.19/188 valves, so it didn’t necessitate new seats. Since I consider myself just slightly better than a horrible head porter, and consider them both very good friends, I figured this would make a good exercise in what we could get done by investing the one thing a low budget guy can afford: time.

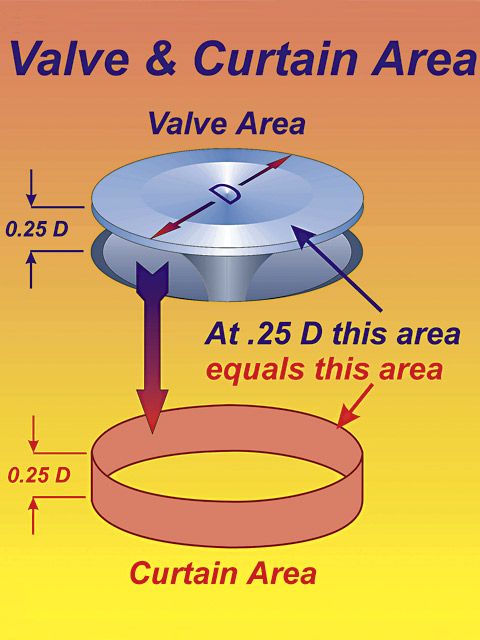

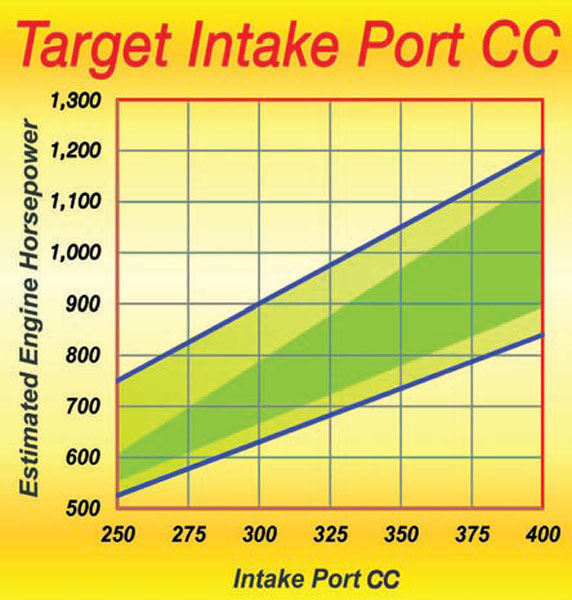

The key to any good engine is its induction package. Good heads flow large volumes of air yet have a conservative enough cross sectional area to assure good ‘recovery’ or velocity as the engine speed transitions on gear changes. If we were racing a 1600 lb. dragster, these castings would have hit the dumpster. The reality was these cars weigh 3500 lbs or more and both carry a streetable 4.10 gear. When matched with 30+ inch tires, these combinations are a bit steep for a big intake runner. I knew there’s not a good short side in the factory heads (the area under the valve where it transitions the port floor) and the finished port volume would limit high rpm breathing. I therefore concentrated on straightening and blending the port to the valve job, working a consistent taper down the runner. We were trying to emphasize low lift flow and velocity, because the cams that would live on the street have less than .600 net lift, once you subtract lash and deflection. Keep in mind, we’re not trying to emulate Sonny Leonard here, so we’re leaving the general shape of the port as GM created it.

I took both set of heads to Ronnie Jewell’s place, a fellow graduate of the Woodchuck University, and had him rough in the new valve jobs of the previously small valve castings. No trick Serdi’s here, just a hand held grinder and some patience. This gave me an interior angle to port to. The open chamber heads on the 468 received the more radical port work, as I felt the swept volume of the engine would require more volume to fill the cylinder. Keep in mind as you look at the photos, we didn’t have the aid of a flowbench as I modified the ports. I had to rely on common sense and educated guesses as I removed material, and admittedly, some good cuts may have been offset by bad ones. The 468’s combustion chambers also received more aggressive work, as I laid the quench side back to aid in the blowdown of the cylinder. Exhaust gasses are purported to actually flow backwards on the GM heads due to the nearly non-existent short side radius. The cut into the quench area aids the gases negotiation of the tight turn. This mod may have been even more beneficial on the nitrous aided 427, but truth be told, I did those heads first and didn’t get as involved with the combustion chamber mods until I did the 468 heads. Lee got the short end of the stick, in that respect. I raised the roofs of both heads’ exhaust ports to the gasket, and blended back into the bowl. I removed significant material on the longside radius, directly under the venturi in an attempt to enhance the low-pressure area beneath the valve seat. This low-pressure area helps draw the spent charge out of the engine and the material removal gives the turning gases more room to make the turn. The accompanying charts show how effective this move was. I directed more of my efforts on the 427’s heads to providing a bit more room on the spark plug side of the chamber to facilitate intake flow. The intake runners of both heads received essentially the same cuts, which are detailed in the accompanying photos. (It is important to note that the heads were flowed only after they were complete, and no modifications to them were performed after we had the flowbench data.)

While I was fiddling with the heads, the blocks were at Carl McQuillen’s machine shop in LeRoy, New York. Carl was a real hitter back in the beginning of the street legal movement, and has parlayed his notoriety into a thriving ‘compound’ in Western NY. He fleshes out many of GM’s brainstorms with his 5 axis CNC machines, EDM’s and skilled help. His shop is spotless, and the work dead-on. We ordered Mike some new pistons, and brought the ones we scored out of the classifieds for Lee’s piece. Once Mike’s pistons arrived, both blocks were over bored to their respective diameters (the 468 to 4.31 and the 427 to 4.28, bringing the cubic inch to 432) and the decks squared and to zeroed. Since Mike’s 468 was a bit higher buck, we had the edges of the bores oblonged to the edges of the gasket’s bore. We then hand blended the cuts to .100 away from the top ring. The chambers of GM heads hang over the bore edges, so while I’m not positive this trick aids airflow, it makes sense on paper. Both blocks were bored and honed with torque plates to ensure good ring seal. Low buck doesn’t mean low effort- meaning attention to the details can make even a modest effort piece run better than expected. Why port the heads and not do what it takes to seal the cylinders? I found them each a set of 7/16 GM rods to replace their ‘peanut butter’ 3/8 rods and had the assemblies balanced to a new ATI damper.

While the lower end components were away, I had Ultradyne grind up a custom cam for Mike’s 468 and Comp Cams whip one up for Lee’s 432. I am a strong believer of big, soft exhaust lobes and crisp aggressive intake lobes. This accomplishes two things, it allows the exhaust plenty of time to get out of the cylinder, and the quicker action of the intake lobe can hold the intake valve closed a smidgen longer reducing dilution while having enough valve opening at peak piston velocity, critical to good cylinder filling. The more controlled exhaust valve action is extra insurance against piston-smacking clearance problems as well. Both cams are similar, with duration in the mid 260’s on the intake and upper 270’s on the exhaust. Gross lift is in the .650 range on the intake and the .630 range on the exhaust. The main difference is in the lobe separation angle; the naturally aspirated 468’s cam was ground on a 108 lsa while the nitrous aided 432 received 110 degrees of separation. A lot of really wordy articles have described the reason for running different separation angles, so let me try to describe the way I understand it very briefly. A tight, or numerically smaller angle delays the exhaust valve opening and closing, trapping more cylinder pressure and increasing overlap, or the time both valves are open. This makes use of the engine’s escaping exhaust gases to pull in fresh charge. The negative is that rpm increases, it takes work for the piston to push the exhaust out and some of the charge starts to fly out the exhaust port during overlap. The 110 lsa on the N20 cam opens the exhaust valve earlier, blowing the cylinder down quicker, and saves the piston from having to push all the extra junk created when the nitrous is on. We don’t want the overlap, because there is so much more pressure with nitrous that there is a tendency for the charge to fly back up the intake tract if the valve is opened too soon. (This is hardly a ‘max effort’ nitrous grind, as Lee won’t be using more than 200 horse of the stuff out of respect for the swap meet forgings.) The 468’s cam was installed at 105 degree intake centerline and the N20 cam went in at 108.

Once the bottom ends for these two engines arrived back home, we gave each of the parts a final close visual inspection. Lee’s 3.76” 427 crank had some scores in it from a sloppy prior assembly, as whoever owned it previously didn’t protect the journal from the rod bolts during assembly. They weren’t deep enough to require a turn, but I polished them with 400-grit sandpaper and a leather strip to be sure. We then mocked everything up to see if either of the engine’s clearances needed adjusting. All the bearing clearances were fine, and there were no exotic tricks as we assembled the shortblocks. Top endgaps for the rings were .018 for the 468 and .022 for the 427 (now 432). The wider gap on the 432 is to reduce the chance of the rings butting with the nitrous on. Nitrous increases cylinder pressure, which creates heat, and encourages the ring to expand. The second rings were .016 for both engines. Piston to valve clearances dictated how much we could cut the heads in search of compression, and we wound up lopping off .030 from the 468 and .060 from the 432. Final compression ratios wound up being 11.83:1 for the 468 and right at 13:1 for the 432. The Strip Dominator Lee had needed a cut to fit the chopped block and heads, but the Edelbrock 454R was just fine as we laid it in place on the 468. Out of respect for the plate nitrous system being installed on Lee’s motor, I radiused the port entries and dividers in the plenum of the Holley. With all the fuel flying around the plenum, nice radiused dividers and walls are cheap insurance against fuel shearing and fallout. The Edelbrock probably would have profited by such a move, but we elected to leave that 5 or so horse on the table and get these things in the cars.

Carburetion for both engines followed suit with the rest of the buildup, as Mike spent a few more bucks and popped for a fresh Pro Systems dominator. Patrick James has a knack for prepping pieces that fit a wide range of applications. The expensive carb may seem out of place with a build such as this, but we saved money in other areas to afford the carb. I’ve personally installed a half dozen or so of his pieces on my customer’s engines, and every one has picked up the program. Lee’s budget dictated we use a box stock carb, so we went with a 950 HP from Holley to top the 432. After break in, we took them both to the dragstrip to see how we fared. The 3600 lb. Camaro went a spinning 10.51 at 129 miles an hour on its second visit to the track! Mike was shifting the 468 at only 6500rpm, a testament to the oval ports’ ability to generate power without high engine speed. Some quick math shows the engine was producing 650 horsepower, in average summer air! Chassis tweaks and launch techniques should put this car in the mid 10.30’s judging from it’s mile per hour. Bear in mind, this car had a tight (by race standards) converter, stalling at 4800 rpm. Part throttle streetability is excellent. Lee’s Regal, sporting a 10” TCI swap meet converter behind the 432 and 10” wide dot tires, reared up and went a 10.95 at 124 on steam, and when we put a 73 pill in the Big Shot plate (about 150 horsepower), it whipped out a 9.98 at 135! We hadn’t even changed a jet or started digging for the hundredths. This thing was making all of 700 horsepower with the nitrous engaged, and since it 60 footed 1.38, there’s plenty of torque to get the car rolling. We’re sure that when the targeted 200 horsepower pills get inserted and we get to the nitty gritty tuning the little 432 will find its way into the 9.50’s.

While these numbers aren’t astounding, they are more than acceptable for the limited cash outlay and scope of the buildups. Small money and respectable et’s aren’t mutually exclusive, and the beauty of these two engines in particular is their ability to create power with very little rpm, reducing the cost of maintenance down the road. Neither of these will ever see the other side of 7000 rpm. Often your competition is overpriced and under thought, leaving you room to exercise your greatest speed part: Your brain. Viva the Woodchuck!

Post Script: Mike Nerwin, always the “tinkerer” decided to try a set of Merlin rectangular ports he scored for a reasonable price from another friend of ours. I performed a very mild bowl blend on them in the past, and knew them to be sound castings. We cc’d the chambers, and they turned out to be 8 cc smaller, resulting in a 1.25 point increase in compression. (11.83 vs. 13.08) A plenum blended Weiand Team G was placed on top, and the rest of the combination was left as is. Weeks of consequent testing were disappointing; the rec ports were consistently .2 slower with an average loss of 2 mph. Mike even removed 75 lbs. from the car in search of the et, but the car still refused to run as it had with the GM oval ports- lighter weight, increased compression and all. Perhaps the intake was the problem, maybe the cam didn’t like the Merlin heads. I really don’t know. I just thought this an interesting twist to throw into the mix… Remember, when bracket racing or cruising the streets, it’s the mid range torque that does the work, and I think this example backs that up.

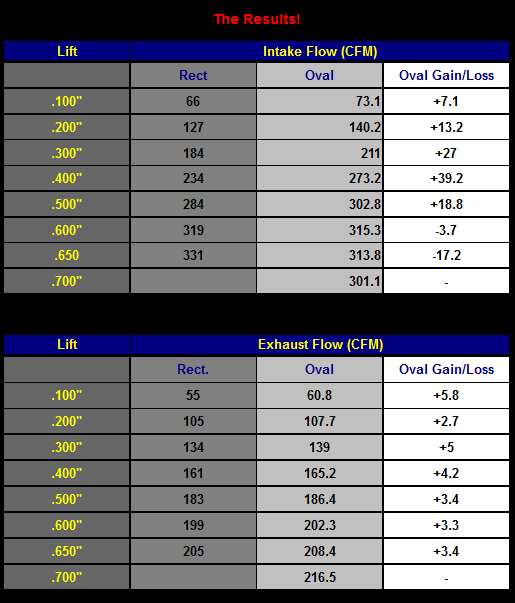

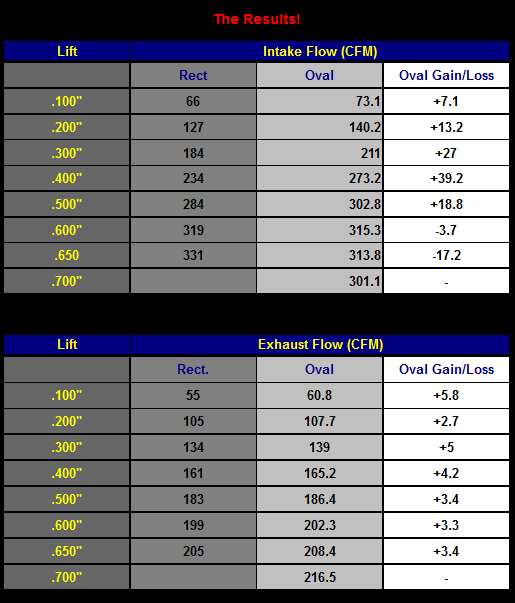

Dave performed the flow tests of both heads on the exact same SuperFlow flow bench. He also performed the port work on the heads. So variables are kept to a minimum. I don't think you'll find a more appropriate "apples-to-apples" comparison. Here is his description of the work done on the heads:

The rect ports were, in my opinion, "mildly ported". The intake runners were gasket matched, the valve pockets were smoothed out to the runners, and both short sides were cleaned and smoothed... and of course any casting lines were smoothed. There was probably room for some improvements on them but not without removing a bunch of material. I was already concerned with them being 320cc on the intakes that the motor was going to be lazy so I didn't want to make them any bigger. Besides, the only gain was going to be at .600" lift and above. The low lift flow #'s were low and I knew it would only get worse with volume.

The oval port intakes were gasket matched to a Fel-pro intake gasket and was blended back about 2" into the stock cast port. Under the intake valve was blended in the same fashion (out to the stock port) to the full size of the valve right up to the seat. The short side was touched to nock off the high spots. Just the basic bowl blend / gasket match to me. The exhaust was bowl blended to the seat size and down into the stock port as well. I spent some extra time on the short side here. The short side was smoothed and radiused very nicely right up to the seat... and I'm talking less than 1/32nd from the seat and polished as well. I took some material off the top of the exhaust guide and blended out to the roof of the port also but the guide still had an obvious flat spot to it. Both intake and exhaust valves were relieved in the combustion chamber area the same amounts.

The Results!

Lift Intake Flow (CFM)

Rect Oval Oval Gain/Loss

.100" 66 73.1 +7.1

.200" 127 140.2 +13.2

.300" 184 211 +27

.400" 234 273.2 +39.2

.500" 284 302.8 +18.8

.600" 319 315.3 -3.7

.650 331 313.8 -17.2

.700" 301.1 -

Lift Exhaust Flow (CFM)

Rect. Oval Oval Gain/Loss

.100" 55 60.8 +5.8

.200" 105 107.7 +2.7

.300" 134 139 +5

.400" 161 165.2 +4.2

.500" 183 186.4 +3.4

.600" 199 202.3 +3.3

.650" 205 208.4 +3.4

.700"

216.5 -

As you can see, the numbers speak for themselves. The oval port heads kick butt up until .650" lift, then the rectangular ports take off. The majority of all street/strip or weekend warrior applications are not running over .650" lift cams. Also, you have to take into consideration that the valve is at max lift at only approximately 8% of the time. So, low and mid lift flow numbers are VERY important. That's where the oval port heads really stand out. Technically, there is no winner or loser. It all depends on the application. This is excellent information to prove that oval port heads are the best choice for "milder" applications that are under 500 CI and have a max RPM in the 6500 range. No doubt, the rectangular port heads have their place. They are the choice for ALL-OUT performance. But for less radical combinations, the oval ports are the choice.