Remember that in Oct. I did 2 runs at our local Maui track and broke a u-joint, then in Nov. I did 5 more runs, then the clutch let go. Nothing nasty about the runs, mid 12's, around 114 mph max, 12" wide cheater slicks, this clutch never should look have failed like it did.

Finally pulled the Centerforce DFX clutch apart and found these toasty parts inside:

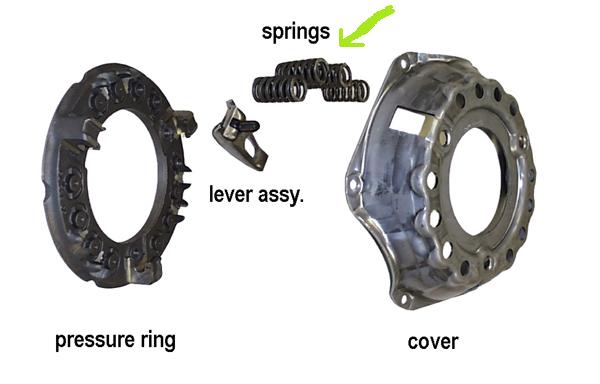

Pressure Plate Side:

Flywheel side:

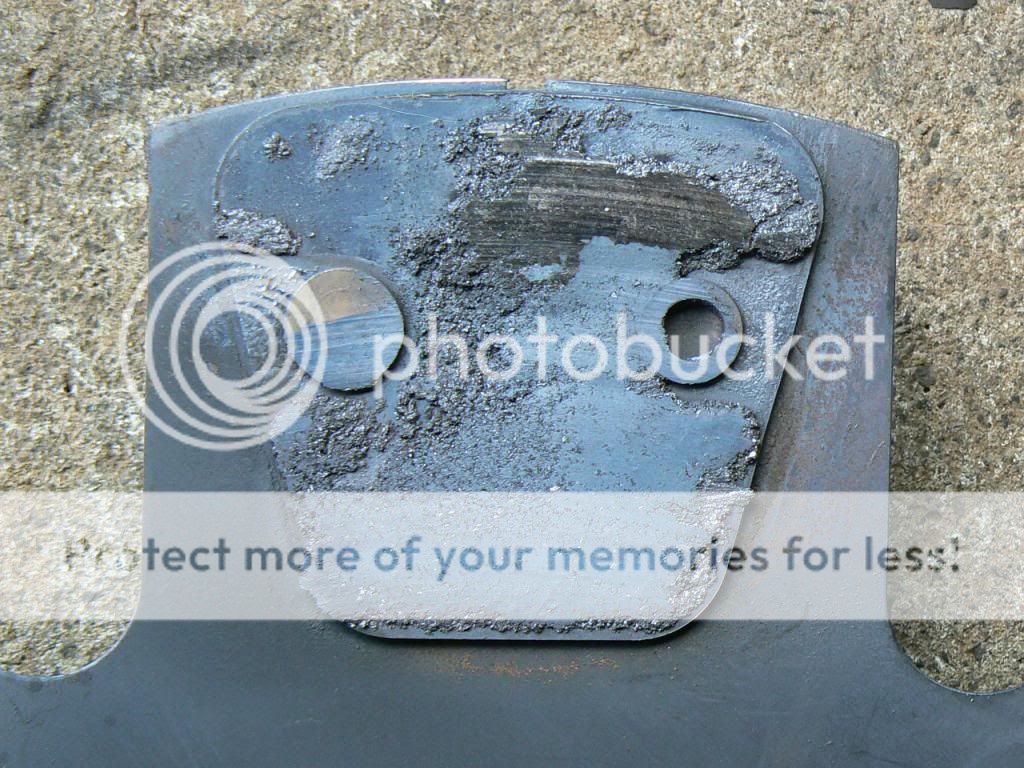

Closeup of the Centerforce DFX Ceramic Clutch Puck:

The flywheel is scored and will need resurfacing or replacement:

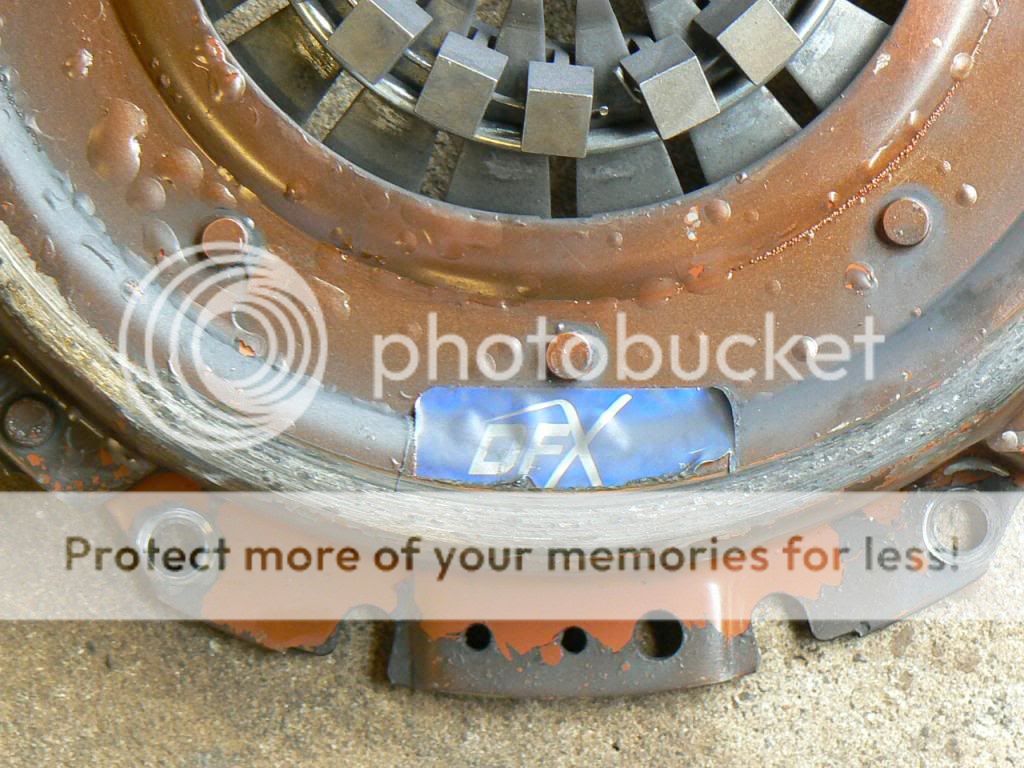

The pressure plate got really hot, blistered the paint:

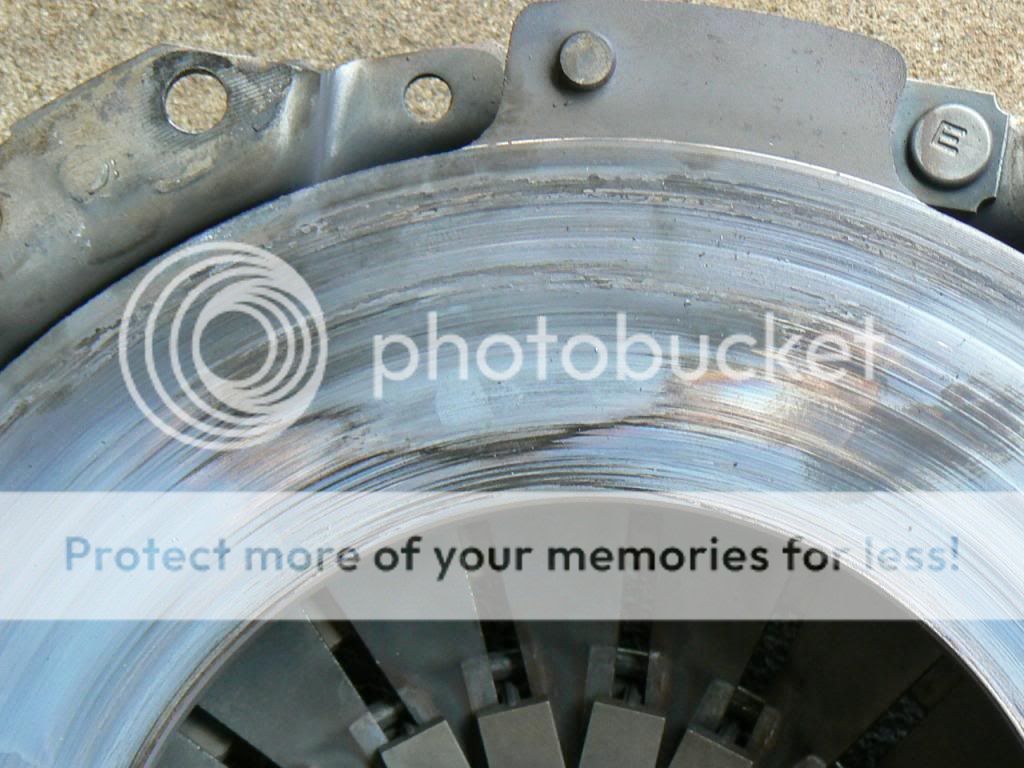

When the clutch surfaces let go, the pressure plate fingers

pushed the throwout bearing further back, and the clutch

arm outside of the pivot closer to the pressure plate shell.

That contact was relieved whenever I stepped on the clutch

pedal, but as the clutch engagement, what was left of it,

was now at the top of the pedal, the clutch arm had to

make contact with the pressure plate shell to engage the

clutch, resulting in the marks you can see here on the outer

edge of the shell. It probably also contributed to the heat

problem.

When I changed from the aluminum to the steel flywheel, I had

originally run into this problem, with the clutch arm hitting the

shell due to the thicker steel flywheel pushing the whole assembly

back. Shortening the pivot ball support 1/16" solved that problem!

(See post above somewhere in this thread....)

And scored the surface of the pressure plate, it will also

need resurfacing or replacement:

I wrote to Centerforce about this failure, so far I have not heard back from them.

I will update you all as I get more info. My advice at the present is to stay way far away from the Centerforce DFX clutch setup. They market it as a street/strip setup. This one never should have failed like it did.

I get the feeling that Centerforce uses guys like us as their R&D department!

Aloha,

Willy