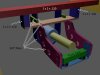

Today I decided it was time to start thinking seriously about the relocation of my

trans mount. The TBucket had a TH350 before, but now I'm building an overdrive

trans called a 200-4R. The 200-4R doesn't have a bolt on tail shaft housing, like

the TH350 did. The mounts are about 6 inch difference if you are only considering

the transmission, but in my situation the mount will have to move about 4 inches.

I used the an old Chevy 350 cu in block for my mock up to see how I'm going to

do this. I'm thinking about dropping down from the top like I did before, that

way when I need to pull the trans out there is nothing under it to get in the way.

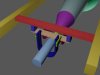

I'm considering this as a possible solution. Add new mount where the WHITE arrow

is below. Then drop down to the trans mount from there.