bytor

Well-Known Member

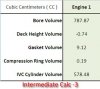

I think I found pparaska's complete post in another forum. The question around using the max or average measurements has me a bit confused.

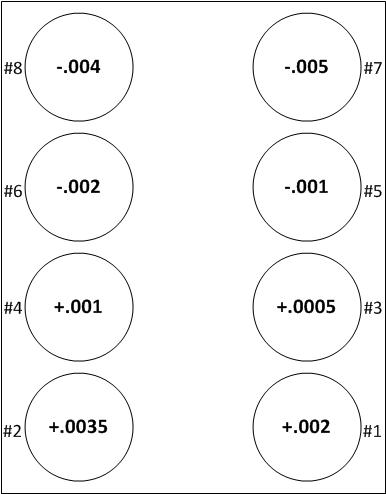

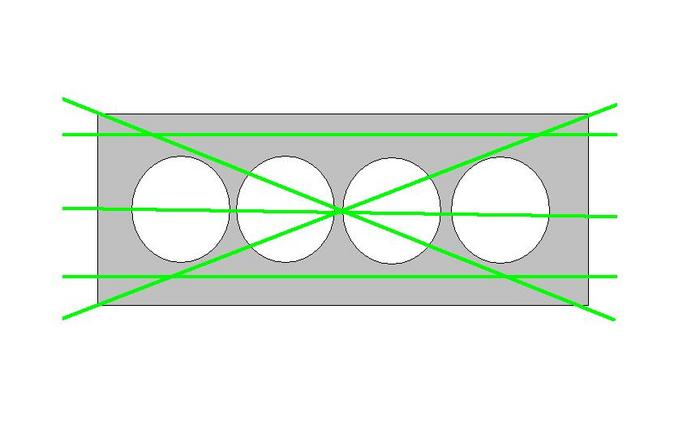

Here's an example of a measurement from that post. My basic question is what do you do with these number? Average, max or just measure from the middle of the piston? I may be over thinking this but I want to make sure I measure this correctly.

Typical readings: (this is cylinder #2, highest recorded heights on even bank)

Outside of block: Min: -0.002" Max: +0.023" (- is below deck, + is above)

Valley side: Min: -0.004" Max: +0.022"

Toward front: Min: +0.002" Max: +0.019"

Toward rear: Min: +0.002" Max: +0.019"

Here's an example of a measurement from that post. My basic question is what do you do with these number? Average, max or just measure from the middle of the piston? I may be over thinking this but I want to make sure I measure this correctly.

Typical readings: (this is cylinder #2, highest recorded heights on even bank)

Outside of block: Min: -0.002" Max: +0.023" (- is below deck, + is above)

Valley side: Min: -0.004" Max: +0.022"

Toward front: Min: +0.002" Max: +0.019"

Toward rear: Min: +0.002" Max: +0.019"