Re: Planning a new 383 build!

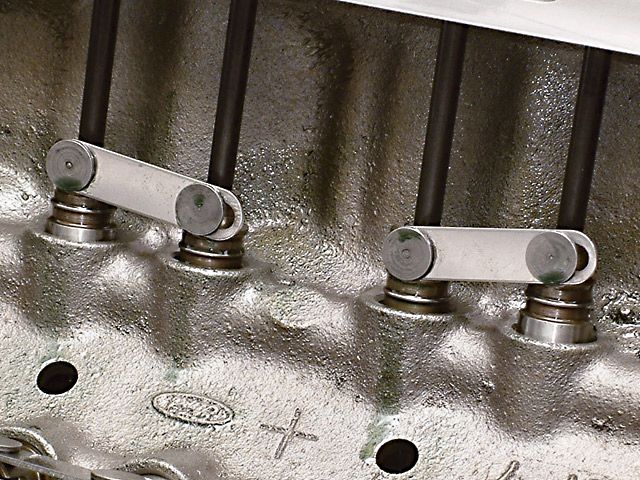

the dog bone , roller lifter ,retainer is supposed to stay in place, just above the lifter bores, but its got a strong tendency to move with the lifters hence the required retention spider spring.

If your planing on exceeding about 400-430 hp, based on use of a standard production sbc engine casting build-up, and BEFORE you spend a good deal of money in machine work on a stock OEM PRODUCTION block, you might want to know the stock block castings are not ideal, FROM A STRENGTH STAND POINT,yes we all know a dozen guys who swear they built 500 hp sbc combos using a stock block as the basic block,but maintaining 500 hp for a few seconds on a dyno, to verify its peak power level, is not the same as beating on the engine frequently on a near constant basis, in a semi race application, stress is cumulative! what they don,t admit ,or realize is that the the blocks designed for low cost production ,not high performance strength, the main caps have a tendency to flex the cylinder walls don,t remain rigid at near max torque loads and the block was designed to operate at or below 5500rpm at or below 400hp

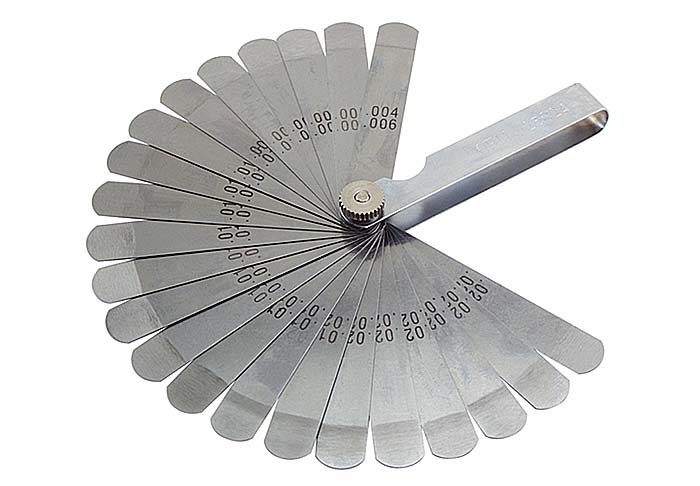

a bit of reading here might be useful... get out a feeler gauge and look at how thick .060, .090, .120 actually is , and consider how easily a thin section of cylinder wall can flex and crack!

viewtopic.php?f=53&t=3897&p=15720&hilit=hone+plate#p15720

viewtopic.php?f=51&t=976

viewtopic.php?f=51&t=125

viewtopic.php?f=51&t=7646

the dog bone , roller lifter ,retainer is supposed to stay in place, just above the lifter bores, but its got a strong tendency to move with the lifters hence the required retention spider spring.

If your planing on exceeding about 400-430 hp, based on use of a standard production sbc engine casting build-up, and BEFORE you spend a good deal of money in machine work on a stock OEM PRODUCTION block, you might want to know the stock block castings are not ideal, FROM A STRENGTH STAND POINT,yes we all know a dozen guys who swear they built 500 hp sbc combos using a stock block as the basic block,but maintaining 500 hp for a few seconds on a dyno, to verify its peak power level, is not the same as beating on the engine frequently on a near constant basis, in a semi race application, stress is cumulative! what they don,t admit ,or realize is that the the blocks designed for low cost production ,not high performance strength, the main caps have a tendency to flex the cylinder walls don,t remain rigid at near max torque loads and the block was designed to operate at or below 5500rpm at or below 400hp

a bit of reading here might be useful... get out a feeler gauge and look at how thick .060, .090, .120 actually is , and consider how easily a thin section of cylinder wall can flex and crack!

viewtopic.php?f=53&t=3897&p=15720&hilit=hone+plate#p15720

viewtopic.php?f=51&t=976

viewtopic.php?f=51&t=125

viewtopic.php?f=51&t=7646