Loves302Chevy

"One test is worth a thousand expert opinions."

WOW. Isky should paying you. I checked their site. Just part numbers and very poor descriptions, IMO. Who cares as long as their parts are good.

My next test was going to be installing a Crane HYD (uses no piddle valves), but I love your idea about putting a couple of solids in there and running the oil pump. I have Crowers on the shelf. I will try both.

I did a bunch of inspecting today, the last thing I did was to change the spin-on oil filter adapter. I won't keep you in suspense - NO DIFFERENCE, as I figured. I will post what I checked tonight with photos. Time to get ready for work.

This is starting to not be fun anymore. The only things it could be now is the rear cam bearing position(doubtful), a plug cutting off the oil supply to both lifter galleries(doubtful), and those lifters.

Quite a few Corvair owners are having this exact problem. The replacement lifter for their engines is the SBC HYD lifter. I'll attach a link later.

I thought you couldn't have EDM holes in HYD lifters, only solids. That's why they use the "camsaver groove" (machined flat on side from oil band to the bottom face) on HYD. It does not supply this extra oiling to the ideal contact point all the time because the lifter spins, but it is certainly better than nothing.Also its not necessary to groove lifter bores using Isky.

They offer EDM Drilled lifter faces for additional cam lobe oiling if want it.

My next test was going to be installing a Crane HYD (uses no piddle valves), but I love your idea about putting a couple of solids in there and running the oil pump. I have Crowers on the shelf. I will try both.

I did a bunch of inspecting today, the last thing I did was to change the spin-on oil filter adapter. I won't keep you in suspense - NO DIFFERENCE, as I figured. I will post what I checked tonight with photos. Time to get ready for work.

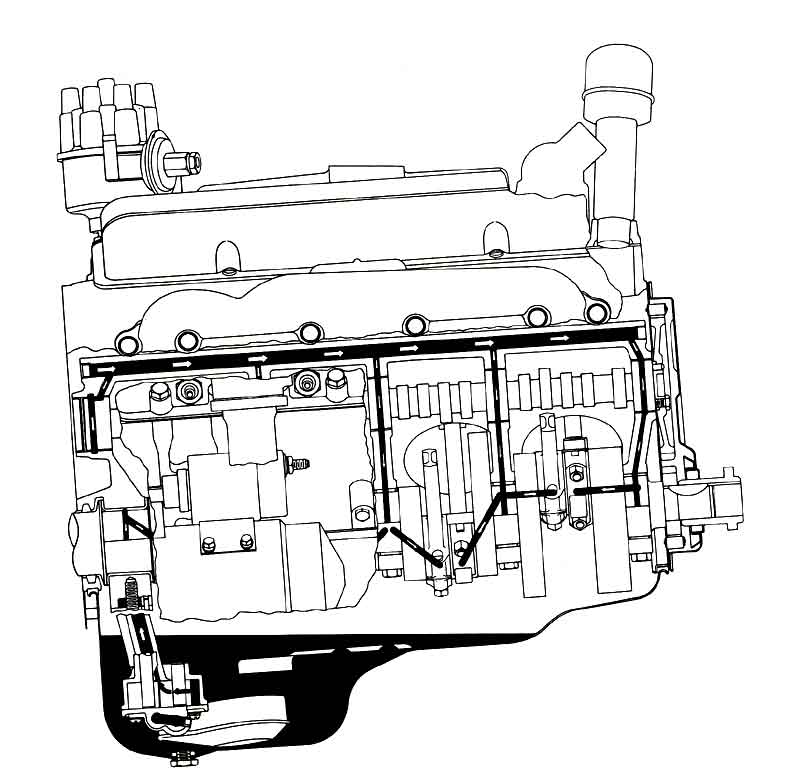

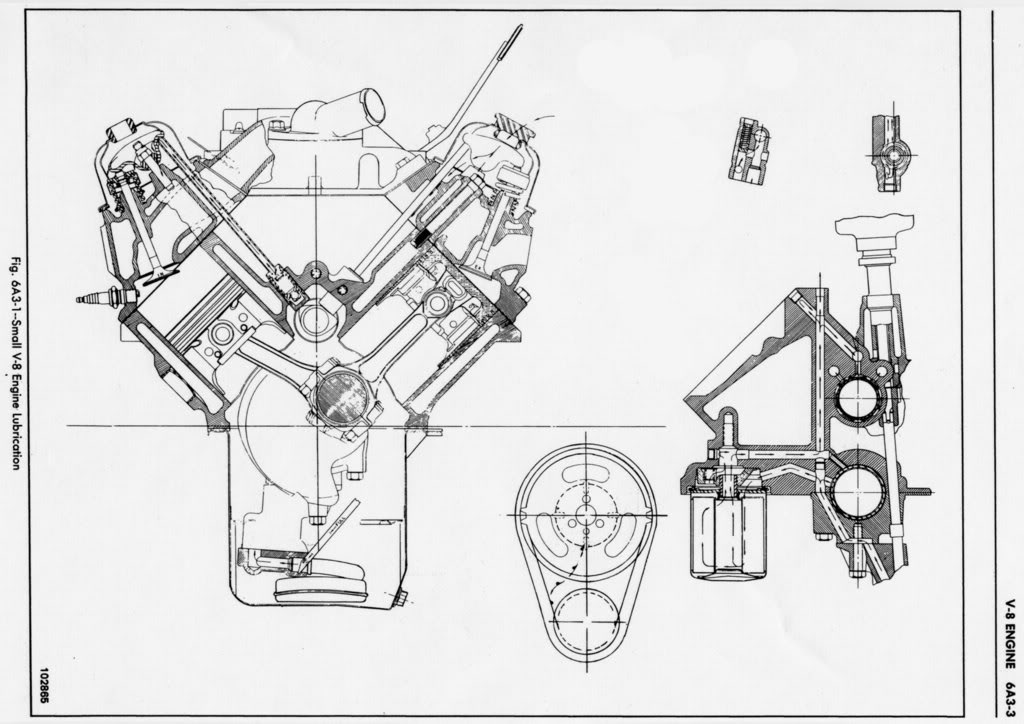

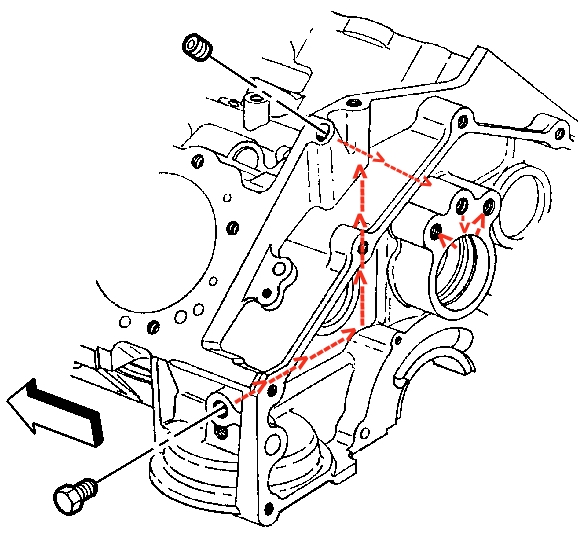

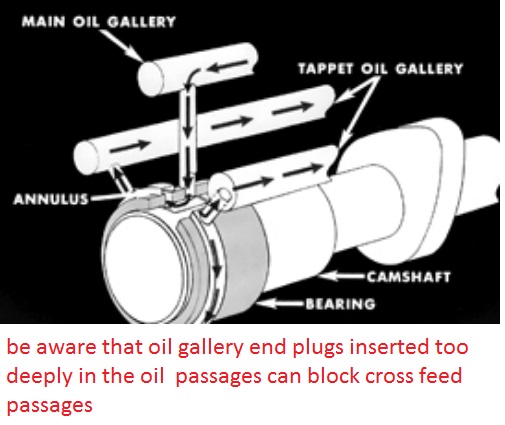

This is starting to not be fun anymore. The only things it could be now is the rear cam bearing position(doubtful), a plug cutting off the oil supply to both lifter galleries(doubtful), and those lifters.

Quite a few Corvair owners are having this exact problem. The replacement lifter for their engines is the SBC HYD lifter. I'll attach a link later.