Loves302Chevy

"One test is worth a thousand expert opinions."

What's that day of the week that you hope your truck was built on? You got one of those.Its about 5 degrees F here.

My 1994 K 1500 Suburban with the 350 TBI engine with Flat tappet hydraulic cam Fired up.

Didn't miss a beat driving home from work.

Lifter bores are stock.

Stock oil pan too.

There is a 1967 -70 Z28 Camaro Melling oil pump on it.

M55A Melling pump.

Standard volume High Pressure.

I had 90 psi on guage when she fired up in the cold tonight.

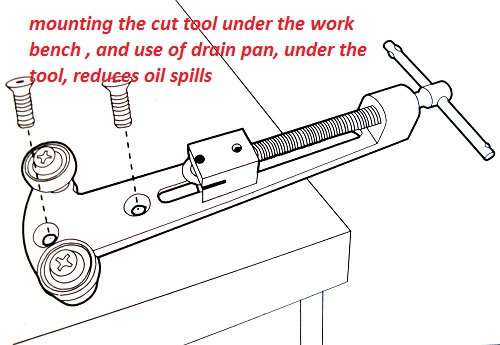

Well, I'm now a couple of steps backwards. Today I inserted 1 lifter each at the rear of each oil gallery and ran the oil pumpWhat's your plan now Loves 302 ?

to see if oil was also fed to the lifter galleries from the front. NO, as I thought. The oil is supplied from the rear, only.

I wanted to see if the lifter bases looked worse than they actually were. So I took the best one and worst one and lightly rubbed

them on a fine flat stone in a circular motion for about 2 minutes each in my parts washer using the solution to "wet sand" the bases.

They cleaned up easily.

Then I was inspecting the lobes through the lifter bores, and they looked good. So good that I thought about just coating the lobes and the Crane (Stanadyne) lifters (originally supplied with this camshaft) with the moly cam paste and trying it again.

But I NEVER get that lucky, and I wanted to coat the lobes well (better than I could through the lifter bores), and all I had left was to remove

the 2-piece front cover and fuel pump to get the camshaft out. When I got to #6 Intake lobe, I found a flat spot. No reusing this camshaft!

Only .038" is gone from the lobe. The lifter that came off this lobe still had all of its crown, but the edge was a little sharp as I ran my finger over it.

I drained the oil to get ready for whatever the next step will be, and saw the silver clouds. My home-made neodymium drain plug had gunk

stuck to it this time. Hopefully, that magnet, the 57# pull ring magnet stuck to the end of the oil filter, and the filter itself trapped the debris.

So I plan to do the diesel fuel flush and run the oil pump while rotating the engine a few revolutions by hand. Then I will blow the block out

with compressed air. When I'm sure it's dry, I will get some new oil in there and run the oil pump again to coat everything. I am NOT taking the bottom end apart. BTW, everything I have done so far is with the intake manifold ON. I'm not removing that either.

The cam bearings look great and my main & rod bearings are these:

King Silicon Alecular Bearings:

The silicon particles help round off high spots on the crank surface during engine operation, which reduces friction & related wear. Because the bearings are unplated, wall variances are reduced by as much as 40% less than tri-metal (over-plated copper lead) bearings. KING's SI bearings easily exceed maximum peak load capacity for car and light duty applications. Minimized debris embedment, SI bearings are unplated and bored, hard-particle debris is instantly flushed through the bearing and filtered out of engine rather than scoring the crankshaft and causing long term damage.

Main KING Silicon Alecular MB557SI .010

Rod KING Silicon Alecular CR865AM .010 + .002 OD w/Housing Bore Resized .002" Larger Than Stock

Now I'm back to choosing a cam & lifters. I'm NOT going roller. And NO GM Delphi type flat disc inertia "piddle" valve lifters - they are in roller lifters also. I like the simplicity of a flat tappet. Less parts to go wrong and no needle bearings going through your engine, destroying everything if the roller lifters fail. Flat tappets still work with the right oil and additives - ask 87vette81big. 360,000 miles and counting. Here comes another ISKY plug.

If I could get a small enough solid flat tappet that would work with my combo, I would. But their rpm ranges begin at about 1000 rpm higher than I can use. With all the work I've done to these heads, I can now probably get away with a single pattern camshaft. I haven't had them flow tested, but I found numbers from the 4" bore 72 cc versions. They flow better then Vortecs. I'm looking for strong upper bottom end and mid range, a fair idle - not real lopey (I don't care about what other people think about the sound - I have to drive it), about 1700-5700 rpm, 10:1 comp, 3.766 bore, 3.75 stroke, 5.7 rods, intake Weiand 8000 EGR - gasket matched and smoothed, Edelbrock #1904 Quadrajet 795 cfm, 1 5/8 headers & 3" single exhaust, deck cl -.002", head gasket (4.065 round bore, .041 thick), 84 Trans Am, Turbo 700R4, 4.10 gears, 28" tires, ? weight (heavy), DAILY DRIVER. A total of .500 max valve lift is all I need, and I have both 1.52 and 1.6 rockers to use. This camshaft was: http://www.cranecams.com/product/cart.php?m=product_detail&p=23791

Grumpy knows this cam.

CraneCams CompuCam 2050 Hydraulic FT

Advertised Duration 272 int./284 exh. 112° LSA / 107° ICL

1800 – 5600 rpm 6200 redline .454/.480 (1.5) .484/.512 (1.6) .484/.486 (1.6/1.52)

272/284 216/228

Seat-to-seat timing (Wallace)

IVO is 29.0 ° BTDC ( - indicates ATDC)

IVC is 63.0 ° ABDC

EVO is 79.0 ° BBDC

EVC is 25.0 ° ATDC ( - indicates BTDC)

Overlap is 54 °

Dynamic Compression Ratio Calculator

(Use seat to seat specs for Intake spec for best results)

Number of Cylinders : 8

Bore in Inches : 3.766

Stroke in Inches : 3.75

Rod Length in Inches : 5.7

Static Compression Ratio : 10 (to 1)

Inlet Valve Closes ABDC : 64 º

Boost Pressure in PSI : 0

Target Altitude : 177 (Feet)

Static compression ratio of 10:1.

Effective stroke is 2.98 inches.

Your dynamic compression ratio is 8.12:1.

Your dynamic cranking pressure is 162.07 PSI.

On the next cam, I might like to use a less intense lobe with 1.6 rockers for longevity.

Heads

World Products 305 Torquer 58cc #4265

175.2 (now) cc intake / 65+ cc exhaust / 58 cc chambers

The intake ports “choke” point now measures .95 x 1.90, which equals 1.805 sq in. and would

allow 5903 rpm for the 334. (Wallace calculator)

Stainless 2.02/1.6 valves stock length undercut stems

Edelbrock Intakes & Alex's Exhausts @30° back cut on INtakes

Fully ported to FelPro 1256 gasket, throats equalized & bowls blended

EXH ports opened to "D" port to match SLP headers

Combustion chambers ground out to edge of head gasket to unshroud the

valves and smoothed

Elgin 9914XK springs (400#/in) set to 1.755 seat = 123# .485 IN lift = 317# (1.270)

from Graham Hansen – High-Performance Chevy Small Block Cylinder Heads:

The ported S/R flows 30+ cfm over the stock Vortec head on the EXH

side (a little down on the INT side), which means that you might be able to get

away with a mild dual pattern or even a single pattern cam with exhaust flow

numbers of this kind. This is the reason I’m using 1.52 rockers on Exhausts.

Also, the valve lifts end up the same (.485”) for both Intake & Exhaust.

72 cc S/R Torquer 2.02/1.6 170cc 1.81 sq in on 4” bore fixture

I've given a cam & lifter set the best chance of survival in this engine. Why does this have to be so difficult?

From the movie AIRPLANE, "I picked a bad week to quit drinking".

Last edited: