87vette81big - Thanks for taking the time to do this with me.

The more I look at the ISKY 264 Mega, the more I'm liking it.

I'll have to look at my heads again and see what my options are for spring pressures.

There is no smiley face for, "Yeah, I'm really looking forward to going through that again."

I will call Ron.

You like to use what you KNOW works. What do you recommend for moly cam lube paste and additive?

I always used Crane paste and EOS, but this time I used the Crane Superlube.

I ran the Wallace calculators on this cam. Here's what I got:

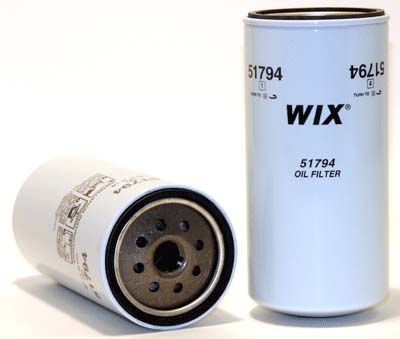

View attachment 6636

Calculated Specs Looks Great Loves 302.

It is what it is. Keep a clear head and complete the task(s) required.

Rest assured your using the Very best from Ron Iskenderien .

The piston rings should be OK. If no cylinder wall scratches are present then a light dingle ball hone may just be required. Or no hone required. Reuse the same piston rings you have now.

Use Clevite P series engine bearings for your Street application. They will deliver 100% reliability for at least 200,000 miles with proper engine maintenance oil changes .

Durabond cam bearings can be used if you like instead of Cleavites. I have used them. Either or works just fine .

Yes I like using what I know works.

There is not much spare cash in anyone's pocket wallet or checkbook today.

There will be again but not this month Jan 2016.

Ask Ron at Isky for his Super Cam Lube Moly formula.

He may include it no cost with your Mega 264 Hyd CL Cam & Lifter Kit.

If you buy direct from him he often can give you a better deal than Summit or others.

Express shipped to you for a nominal charge.

I always buy Direct from Ron .

Any tips Grumpy gives for Cam and Lifter lube is excellent.

Crane made excellent products and still do.

I have used their pour in Cam Super Lube bottle with Zero issues.

A dash of Marvel Mystery oil as Grumpy Loves will not hurt a thing.

I have been using it myself on a regular basis in my own vehicles.

I pay $3.88 a quart at my local Wally world - Wal Mart.

GM EOS is the very best if you can find it.

Pour 1 quart over the Cam & Lifters after installation right before you bolt the intake manifold back on.

Timing cover & oil pan installed before hand on your 334 ci SBC V8 engine.

In the past I used 1 bottle Of GM EOS poured over over the Cam & Lifters .

ISKY Moly Camshaft lube on the C & L .

Another 1 bottle of GM EOS added to the oil pan from the valvecover oil fill port.

8 - quarts of Castrol 10w30 conventional Dino oil in my Milodon Pontiac V8 Race oil pan.

Its a high capacity oil pan.

I never ever had a camshaft fail or lifters fail.

ISKENDERIEN CAMSHAFT & LIFTERS USED.