Trying to get my head back in the game, I was ready about my three setup options

with the 1-2 and 3-4 accumulator valves. By just reading the manual, I should pick

the last option to get the firmest shift possible. But I wondered since most shift kits

are for cars much heavier than mine by 1500-2000 lbs, I decided to send Chris at

CK Performance an email to confirm the right option.

Luckily for me I sent that email because he suggested starting with the softest

option ....completely opposite of the the manual.

I would start with the softest settings. As for the governor we need to

know where it shifts at now and what governor you are using.

-----Original Message-----

From: rickmiller <rickmiller@cox.net>

To: trannyman0101 <trannyman0101@aol.com>

Sent: Thu, May 16, 2013 11:29 am

Subject: 24RSRK/A Shift Kit Options

Chris,

I need to confirm which option to choose for the 1-2 & 3-4 accumalator in the

200-4R trans. You recommend for anything over 325 HP to eliminate the valve

and use the 1/4" cup plugs per your instruction manual.

My car is a TBucket that only weighs about 1800 lbs and will mostly be used for

street/cruising, with the occasional blast. Should I still use 1/4" cup plugs or

drop back to the middle option from your instructions for the shift kit 24RSRK/A.

Car/Engine Specs:

Your D5 2800 RPM stall converter

Ford 9" , 3.7:1 limited slip differential

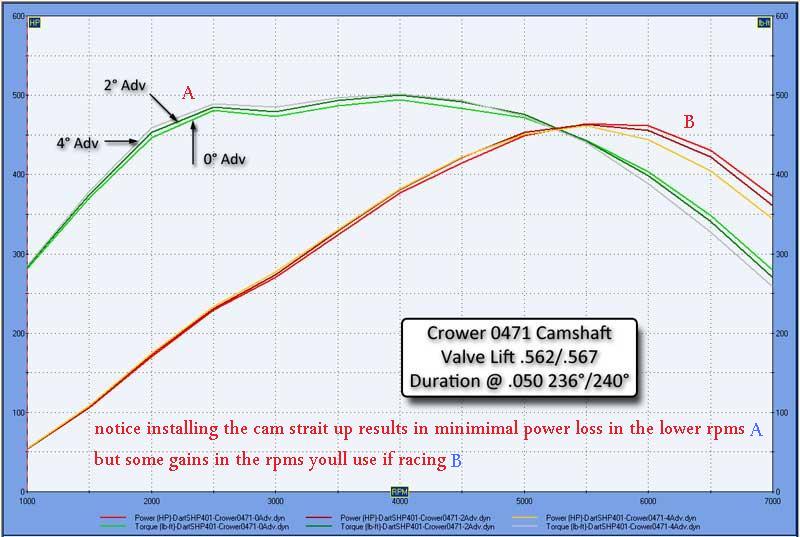

400 cuin SBC (See HP/Torque Attached)

Crower Camshaft 00471

Below is the page of the manual I was reading with my options for configuring the trans.

Last edited: