I don,t remember discussing the installation of a remote mounted trans fluid cooler on your t-bucket,

now it might not be mandatory, but its always a good idea on a car that has a high stall converter as they generate a good deal more fluid heat than a stock transmission. AS always before you go jumping into any mods on your car, But I would suggest at least installing both a fluid TEMP and trans pressure gauge so you can see what the trans fluid temps really are before spending the time and effort and cash required, but I think you might find it worth the effort

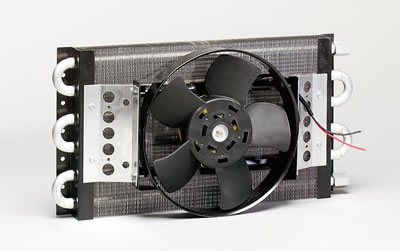

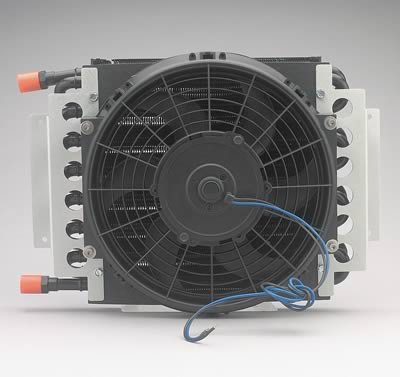

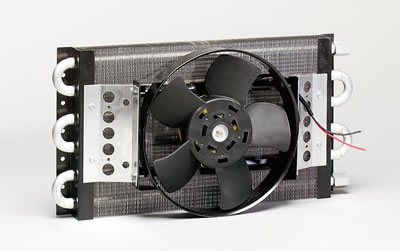

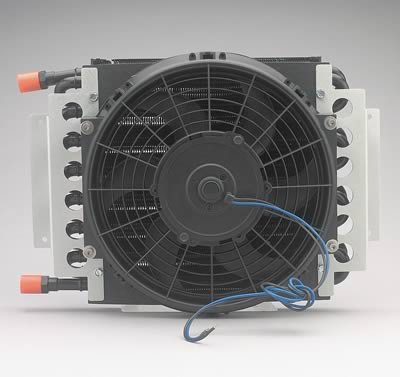

heres the cooler I installed on my corvette, It was the most efficient one I found that would fit at the time I looked, but it has AN#6 lines, it works just fine but if I had the chance ID select a slightly smaller and thicker cooler with larger line size , when I measured the corvette for the trans cooler I carefully measured the available space I intended to use and selected the largest most efficient trans fluid cooler that would fit in that space but forgot about the room that was required to route the trans fluid lines and fittings , making installing it in its intended location a true P.I.T.A. so I wound up mounting the trans fluid cooler where my spare tire goes normally, in the rear of the car, (NEW GUY STUPID MISTAKE), I,m pointing out this personal screw -up so you might avoid that little flaw in your plans should you choose to install a trans cooler

http://www.summitracing.com/parts/PRM-12318/

BUT having learned a good deal, since that time, if I had to do it over I would go with a slightly smaller size (length and height) cooler with larger DIAMETER AN#8 lines if I was doing it today

http://www.summitracing.com/parts/der-15800/overview/

BE AWARE OF UNDER THE CAR CLEARANCE ISSUES

READ THIS LINK

http://garage.grumpysperformance.co...n-cooler-info-and-derale-trans-cool-pans.662/

now it might not be mandatory, but its always a good idea on a car that has a high stall converter as they generate a good deal more fluid heat than a stock transmission. AS always before you go jumping into any mods on your car, But I would suggest at least installing both a fluid TEMP and trans pressure gauge so you can see what the trans fluid temps really are before spending the time and effort and cash required, but I think you might find it worth the effort

heres the cooler I installed on my corvette, It was the most efficient one I found that would fit at the time I looked, but it has AN#6 lines, it works just fine but if I had the chance ID select a slightly smaller and thicker cooler with larger line size , when I measured the corvette for the trans cooler I carefully measured the available space I intended to use and selected the largest most efficient trans fluid cooler that would fit in that space but forgot about the room that was required to route the trans fluid lines and fittings , making installing it in its intended location a true P.I.T.A. so I wound up mounting the trans fluid cooler where my spare tire goes normally, in the rear of the car, (NEW GUY STUPID MISTAKE), I,m pointing out this personal screw -up so you might avoid that little flaw in your plans should you choose to install a trans cooler

http://www.summitracing.com/parts/PRM-12318/

BUT having learned a good deal, since that time, if I had to do it over I would go with a slightly smaller size (length and height) cooler with larger DIAMETER AN#8 lines if I was doing it today

http://www.summitracing.com/parts/der-15800/overview/

BE AWARE OF UNDER THE CAR CLEARANCE ISSUES

READ THIS LINK

http://garage.grumpysperformance.co...n-cooler-info-and-derale-trans-cool-pans.662/

Last edited by a moderator: