You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TBucket Engine Project (Dart SHP)

- Thread starter Indycars

- Start date

8

87vette81big

Guest

Your Running against Real Race Cars Rick.

To Compete & Win you have to be geared right.

Seen No Massive Tire spin & T going sideways.

Current Mickey tires Fine.

There is a reason why 4 & 5 series Rear Diff gears are made & used.

To Compete & Win you have to be geared right.

Seen No Massive Tire spin & T going sideways.

Current Mickey tires Fine.

There is a reason why 4 & 5 series Rear Diff gears are made & used.

Just move to Oklahoma, easy peasy!!!mathd said:Darn, wish i had a place like that locally.

How is the carb tuning?

It look like its pretty much in the ball pack.

probably something wrong with my computer.. i have to turn the volume on full and i can barely hear the video. Its hard for me to tell how the engine sounds like.

Am just curious, how it feel when you floor in on the track? and when you give it a quick rev?.

Accelerator pump tuning can be a pita, and that will throw your launch/60 feet time to the garbage.

But maby its your stall speed/torque converter, honestly i have zero knowledges with auto's.

Edit: to me it look like, with a little more traction as stated above and more off idle throttle response it will get very interesting

I'm getting plenty of sound when I play the videos, I even have to turn it down

from full volume some....sorry.

It doesn't seem to "crack the whip" when I rev it out of gear. I think the carb has

a way to go yet, I will post spark plug pics later today.

philly said:what shocks are on the bucket? are they adjustable?

The fronts I just replaced with some non-adjustable QA1's.

Rear shocks are Pliacell PN: 3192327. Build date is 164-71 or 164th day of 1971.

They fit front of Corvette, Camaro or Chevelle.

87vette81big said:Nothing broke like I feared so make the best of what you have for now

4.33 or 4.56 gears with 31" tall tires be a great combo for Strip action.

You still have 200R4 overdrive.

Best Value for your $$ is a gear change. $300 bucks in parts or less.

9" Is small enough the Hogs head to ship to me & I do it.

Or do it yourself .

You guys had me worried about those mounts for the front of the rear traction

bars. I checked them after every pass.

Now a gear change is something that I would like to do. Going from a 28 inch rear

tires to 31 inch is really hurting my overall ratio.

What tools would I need ??? I already have a dial indicator.

philly said:dont worry rick you arent alone in your high speed/ no cage fear... once you overcome it... greatness is the next step.

Let me see if I can re-write that statement please.

"dont worry rick you arent alone in your high speed/ no cage fear... once you

overcome it... the next step is the grave !!!

Last edited:

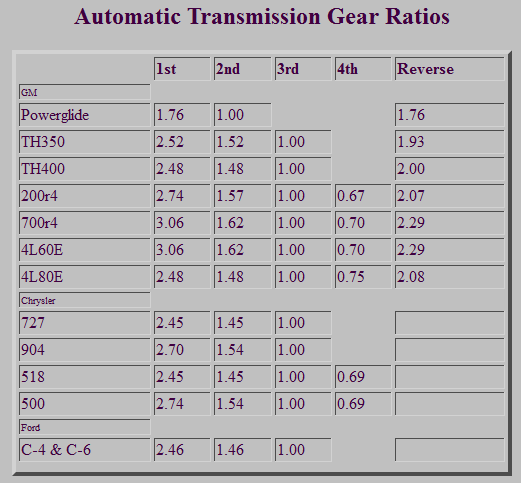

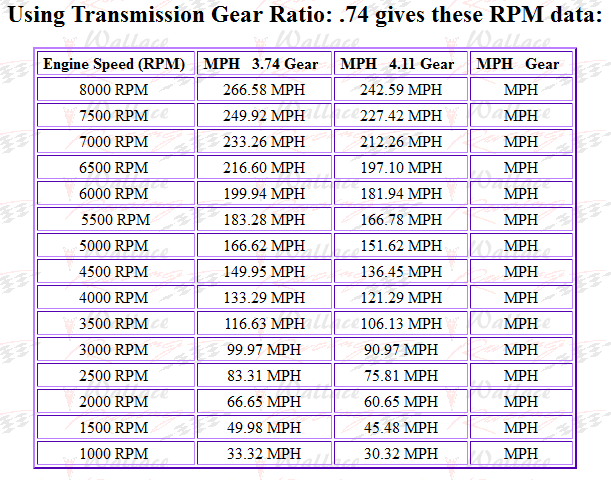

in most cases youll want the transmission first gear x the rear gear ratio to fall in the 10:1-10.5:1 range and the cruise rpm at 70 mph on a street driven car to fall at a semi-reasonable rpm level where your NOT buzzing the hell out of your cars engine in top gear, but with an over drive transmission you might find OD places the cars cruise rpm below the converter stall speed, this is rarely a problem, as long as you have a decent trans fluid cooler and make reasonable choices, in components.

a good compromise obviously will require some measurement of your tire diam. and a few calculations

the 200r4 first gear=2.74 x a 3.73 rear gear =10.22, or about ideal, for a performance cars drive train, but lets look further, if you have that trans and 31" tires this is what swapping to a 4.11:1 rear gear does

if you stay with the 3.73:1 rear gear ratio 2830 rpm in third gear, and OD 2100rpm at 70mph

if you swap with the 4.11:1 rear gear ratio 3113 rpm in third gear, and OD 2320rpm at 70mph

http://www.wallaceracing.com/gear-speed.php

http://users.erols.com/srweiss/calcrpm.htm

http://www.race-cars.net/calculators/et_calculator.html

http://www.datsuns.com/Tech/whentoshift.htm

http://www.frontrange4x4.com/forums/sho ... nformation

http://www.carcraft.com/techarticles/cc ... to_01.html

http://purplesagetradingpost.com/sumner ... index.html

http://www.tciauto.com/tc/gear-ratios

If I did go to the 4.11, that would put me a 11.3, outside the preferred

10:1 to 10.5:1 range. Still it appears to be the right thing to do at this

time. The ratio doesn't take into account the tire diameter. It would make

it harder for me doing manual shifts and driving one handed. Really really

need to get the trans to shift automatically at the right RPM, then driving

would be much easier.

You say the cruise RPM might drop below the TQ stall speed, but would it

matter if the TQ locks up mechanically ???

probably not if the cruise speed is within about 20% of stall speed and having a TQ locks up mechanically has to be an advantage under some conditionsIndycars said:

If I did go to the 4.11, that would put me a 11.3, outside the preferred

10:1 to 10.5:1 range. Still it appears to be the right thing to do at this

time. The ratio doesn't take into account the tire diameter. It would make

it harder for me doing manual shifts and driving one handed. Really really

need to get the trans to shift automatically at the right RPM, then driving

would be much easier.

You say the cruise RPM might drop below the TQ stall speed, but would it

matter if the TQ locks up mechanically ???

8

87vette81big

Guest

Posting from my phone again Rick so long writeups I wond do.

It all changed when you went with a Taller Tire put back.

The Rolling Radius from axle shaft centerline to the ground.

Like I said before those Gearing charts are only ballpark figures

Not written in stone rules.

4.11 be a noticeable improvement.

I would like to see a 4.30-4.56 myself.

I recall you have a wide power band Crower Cam.

Use 4.11.

Need an Inch Pound beam style torque wrench.

A hydraulic or Large heavy duty arbor press.

A Bearing & Shim installation kit.

Need to know if you have 28 or 31 spline axle shafts in 9" rear.

Remove an axle shaft & count splines. Necessary because have to order the right installation kit.

Pontiacs need 4.56-5.38 gears with 28"-31" tall tires to get into 9's normally aspirated.

Want to Race & win Have to use right hardware.

Not racing slow stock Corvettes at Your Hometown Nationals in Oklahoma.

They are nit Fucking around Rick.

It all changed when you went with a Taller Tire put back.

The Rolling Radius from axle shaft centerline to the ground.

Like I said before those Gearing charts are only ballpark figures

Not written in stone rules.

4.11 be a noticeable improvement.

I would like to see a 4.30-4.56 myself.

I recall you have a wide power band Crower Cam.

Use 4.11.

Need an Inch Pound beam style torque wrench.

A hydraulic or Large heavy duty arbor press.

A Bearing & Shim installation kit.

Need to know if you have 28 or 31 spline axle shafts in 9" rear.

Remove an axle shaft & count splines. Necessary because have to order the right installation kit.

Pontiacs need 4.56-5.38 gears with 28"-31" tall tires to get into 9's normally aspirated.

Want to Race & win Have to use right hardware.

Not racing slow stock Corvettes at Your Hometown Nationals in Oklahoma.

They are nit Fucking around Rick.

8

87vette81big

Guest

There is A centrifugal Governor in your 200R4.

Needs to be upgraded Rick.

Allow 5500-6200 Rpm upshifts

Call Chris at CK PERFORMANCE MONDAY MORNING AGAIN.

Needs to be upgraded Rick.

Allow 5500-6200 Rpm upshifts

Call Chris at CK PERFORMANCE MONDAY MORNING AGAIN.

8

87vette81big

Guest

Its why I have been Nabbing up as many 57-64 Pontiac Olds 9.3's as I can past few years Rick from Gasser Drag cars. Hardware & gears. They never self destruct. Built heavy like a Dana 60.

Have multiple 3rd members ready to bolt in.

Street. Full Drag Race. Less than 15 minutes time change over.

Have multiple 3rd members ready to bolt in.

Street. Full Drag Race. Less than 15 minutes time change over.

Ok, here are the pics of the spark plugs. Just to remind you, I changed the

plugs after I got to El Reno, made 6 passes including driving back to starting

line. Then I removed them and took pictures right then at the race track. I

still have them numbered, so if we need more pics, that won't be a problem.

.

plugs after I got to El Reno, made 6 passes including driving back to starting

line. Then I removed them and took pictures right then at the race track. I

still have them numbered, so if we need more pics, that won't be a problem.

.

Last edited:

8

87vette81big

Guest

No Rick.Indycars said:

Thanks Brian for that list. I have the KD Tools 3/8 inch beam style torque wrench

that goes 0 - 600 inch/lbs.

I need to call Chris anyway, I want firmer shifts in all gears.

Needs to be 0-100 inch Snap On Tool Room Gold Dial face internal beam style.

Or 0-50 inch/lb .

Need the accuracy

Pinion preload most important.

0-50 typically 1/4" socket. I use multiple adapters to get to 1/2"-3/4" drive sockets.

Photograph both of mine later for you.

8

87vette81big

Guest

The Carb needs further dialing in Rick.

Slight lean I think WOT.

Ground electrode strap has funny splash deposits.

Engine still breaking in perhaps.

Slight lean I think WOT.

Ground electrode strap has funny splash deposits.

Engine still breaking in perhaps.

87vette81big said:No Rick.

Needs to be 0-100 inch Snap On Tool Room Gold Dial face internal beam style.

Or 0-50 inch/lb .

Need the accuracy

Pinion preload most important.

0-50 typically 1/4" socket. I use multiple adapters to get to 1/2"-3/4" drive sockets.

Photograph both of mine later for you.

I have this one, will it work ?

Last edited:

looking at those plugs, Id say , my first impression is ,your a bit to much on total ignition advance, IE if its now at 37-40 total advance bring it back 2 degrees on the TOTAL advance but not initial

your running as bit lean in the upper rpm range but rich in the lower rpms, (Exactly opposite of what it should ideally be)

Id look at enriching the power valve one step,and maybe then run it a few times and check again

your running as bit lean in the upper rpm range but rich in the lower rpms, (Exactly opposite of what it should ideally be)

Id look at enriching the power valve one step,and maybe then run it a few times and check again

Last edited by a moderator:

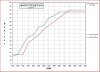

grumpyvette said:looking at those plugs, Id say , my first impression is ,your a bit to much on total

ignition advance, IE if its now at 37-40 total advance bring it back 2 degrees on the

TOTAL advance but not initial.

I thought I had the timing set at 36°(Red Curve), but I should confirm that before

proceeding with that assumption. I've also noticed that the timing is very stable

until it reaches about 3000 RPM, then it starts bouncing around. I observed this

when I was getting the numbers for the timing curve below.

.

Last edited:

8

87vette81big

Guest

That will work Rick Nice.Indycars said:87vette81big said:No Rick.

Needs to be 0-100 inch Snap On Tool Room Gold Dial face internal beam style.

Or 0-50 inch/lb .

Need the accuracy

Pinion preload most important.

0-50 typically 1/4" socket. I use multiple adapters to get to 1/2"-3/4" drive sockets.

Photograph both of mine later for you.

I have this one, will it work ?

Mine has the Tattle Tale Adjustsble needle that lights up a Pen light bulb.

30-40 years old but works beautiful . Very Avcurate.