You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unforgiven Project

- Thread starter Unforgiven

- Start date

Maniacmechanic1

solid fixture here in the forum

Awesome!UPDATE:

Ryan went and checked the block out and this is what he sent me.

View attachment 11880

View attachment 11881

We are going to pick it up after work tomorrow.

I think someone was looking down on me from above!

Loves302Chevy

"One test is worth a thousand expert opinions."

https://www.competitionproducts.com/Dart-SHP-Chev-SB-Cast-Iron-Blocks/products/1662/

DART BLOCKS & FREE FREIGHT. Take your pick.

What size CI were you planning?

DART BLOCKS & FREE FREIGHT. Take your pick.

What size CI were you planning?

Unforgiven

solid fixture here in the forum

https://www.summitracing.com/parts/nal-24502503

Using the part number off the supplied data sheet he took a picture of... this is the block

Using the part number off the supplied data sheet he took a picture of... this is the block

Unforgiven

solid fixture here in the forum

Brian... This is not a production block.

Its an aftermarket RACE block By GM Performance

From what I am reading and going by part numbers that were supplied with the block

This is what I was hoping for!

Summit racing is selling that block for $2750

Its an aftermarket RACE block By GM Performance

From what I am reading and going by part numbers that were supplied with the block

This is what I was hoping for!

Summit racing is selling that block for $2750

Unforgiven

solid fixture here in the forum

Yes Grumpy, I am going tonight to pick it up. Ryan is going to hot tank it and check it all over.

The story I got was that it's one of the older guys that work at his shop, that use to be heavily into racing.

He purchased this block awhile ago and never used it. He got out of racing , and the block has just been sitting in his garage ever since. He found out about the incident that had happened with my block, and offered up the block to me.

I will get more info straight from him tonight. I am really excited about this block.

The story I got was that it's one of the older guys that work at his shop, that use to be heavily into racing.

He purchased this block awhile ago and never used it. He got out of racing , and the block has just been sitting in his garage ever since. He found out about the incident that had happened with my block, and offered up the block to me.

I will get more info straight from him tonight. I am really excited about this block.

Unforgiven

solid fixture here in the forum

HARD BLOCK FILL IT.

DON'T SCREW AROUND.

Did you see the wall thickness on it Brian?! .570"

Ryan sonic checked it last night.

It ain't going to move at that thickness!

This is a bran-new block never used.

Maniacmechanic1

solid fixture here in the forum

Do it anyhow.Did you see the wall thickness on it Brian?! .570"

Ryan sonic checked it last night.

It ain't going to move at that thickness!

This is a bran-new block never used.

Grumpy avoids SBC

you should be just fine with a block that sonic checks on the bore walls that thick, without any block fill.

If I had a block that sonic checked at over .500, with the bore diam.

I would not even consider filling the coolant voids as its all but pointless

If I had a block that sonic checked at over .500, with the bore diam.

I would not even consider filling the coolant voids as its all but pointless

Last edited:

Unforgiven

solid fixture here in the forum

THANK YOU RICK for crossing your fingers!

I'll be darned if it is not that racing block.!

I was searching P/N numbers and found this....

P/N 24502503 4.00" Bore Cast Iron Racing Bow Tie Bare Block

This block is "CNC" machined from a raw casting P/N 10051184. All traditional racing modifications are provided by the factory. The heart of this block starts with a siamesed bore cylinder case at a 3.995" bore, but can be bored to 4.155". This case is then blueprinted on the cylinder decks (9.025" deck height), front of case, rear of case, and oil pan rail surfaces as well as the head dowel locator pin locations. In addition all galleries required for dry sump oil system operation are drilled and tapped for pipe. 8620 steel bearing caps are installed on all locations on the block. The intermediate main bearing caps have the outer 7/16" diameter studs installed at a 20º splay, while the front bearing cap has 7/16" diameter studs on the inner locations and 3/8" diameter straight bolts on the outer locations. The rear bearing cap is a two- stud (7/16" dia.) configuration and utilizes a two-piece rear seal design. After installation of the steel bearing caps, the block is align bored. Use cam bearing kit P/N 12370843 only.

Technical Notes: The above bore sizes are after honing .005" from the cylinder by a professional engine builder. Special features are: Priority main oiling; Bearing cap inner bolts spread .210 to allow use of "2.65" dia. journal cranks on properly modified blocks; Sonic bore check (data provided); Enlarged cam bosses front and rear to allow use of larger bearings; Enlarged lifter bosses; Early model two-piece rear main seals; Uses pre-1986 oil pans; and Uses premium quality studs and 8620 20º steel splayed main bearing caps.

Read more: http://forums.superchevy.com/chevy-...-bearing-bore-in-bow-tie-block/#ixzz5jZim8V3Z

Follow us: @SuperChevy on Twitter | SuperChevyMag on Facebook

I'll be darned if it is not that racing block.!

I was searching P/N numbers and found this....

P/N 24502503 4.00" Bore Cast Iron Racing Bow Tie Bare Block

This block is "CNC" machined from a raw casting P/N 10051184. All traditional racing modifications are provided by the factory. The heart of this block starts with a siamesed bore cylinder case at a 3.995" bore, but can be bored to 4.155". This case is then blueprinted on the cylinder decks (9.025" deck height), front of case, rear of case, and oil pan rail surfaces as well as the head dowel locator pin locations. In addition all galleries required for dry sump oil system operation are drilled and tapped for pipe. 8620 steel bearing caps are installed on all locations on the block. The intermediate main bearing caps have the outer 7/16" diameter studs installed at a 20º splay, while the front bearing cap has 7/16" diameter studs on the inner locations and 3/8" diameter straight bolts on the outer locations. The rear bearing cap is a two- stud (7/16" dia.) configuration and utilizes a two-piece rear seal design. After installation of the steel bearing caps, the block is align bored. Use cam bearing kit P/N 12370843 only.

Technical Notes: The above bore sizes are after honing .005" from the cylinder by a professional engine builder. Special features are: Priority main oiling; Bearing cap inner bolts spread .210 to allow use of "2.65" dia. journal cranks on properly modified blocks; Sonic bore check (data provided); Enlarged cam bosses front and rear to allow use of larger bearings; Enlarged lifter bosses; Early model two-piece rear main seals; Uses pre-1986 oil pans; and Uses premium quality studs and 8620 20º steel splayed main bearing caps.

Read more: http://forums.superchevy.com/chevy-...-bearing-bore-in-bow-tie-block/#ixzz5jZim8V3Z

Follow us: @SuperChevy on Twitter | SuperChevyMag on Facebook

Unforgiven

solid fixture here in the forum

I think Ryan may have miss typed that sonic test number?

Through all my research I have found that that block has .370 wall thickness

which is still awesome in itself.

Through all my research I have found that that block has .370 wall thickness

which is still awesome in itself.

THANK YOU RICK for crossing your fingers!

I'll be darned if it is not that racing block.!

Well it seems that the problem with the first block was really a blessing ! Congrats on finding a

great replacement block !

Unforgiven

solid fixture here in the forum

I had an exciting experience last night when I went to look at that block.

Out of respect for the man, I cannot show pictures or give alot of info about him, but....

He is a major R&D person who is contracted by A very well known automotive company!

I was in awe when I walked into his shop. I walked in feeling all of my 6' 1" frame, but left his shop feeling 2" tall!

I was very humbled, and grateful that I met this man.

Grumpy, you would like him! It was BBC heaven!

After I got over the overwhelmingness of the machinery, welders, tools and the layout of his (basically 30x60) shop, not including his office or the separate room for all grinding and sand blasting.

I could not help but notice a 272" dirt dragster sitting among another smaller dragster and the coolest sandrail

I have ever seen! There where BBC's on engine stands , some for customers and some where his. One N/A motor made 1600 HP.

There were trophies and pictures ( some with some VERY well known players) all over. All too cool!

We talked for about and hour to get to know each other better before we ventured over to the block he was offering

to me.

It is the race block I was hoping for! It has alot of surface powder rust on it but no scaling.

The block has never had a piston in it. It has to have alot of machining done to it. But In my case, there,s no costs.

It has the steel splayed main caps and studs.

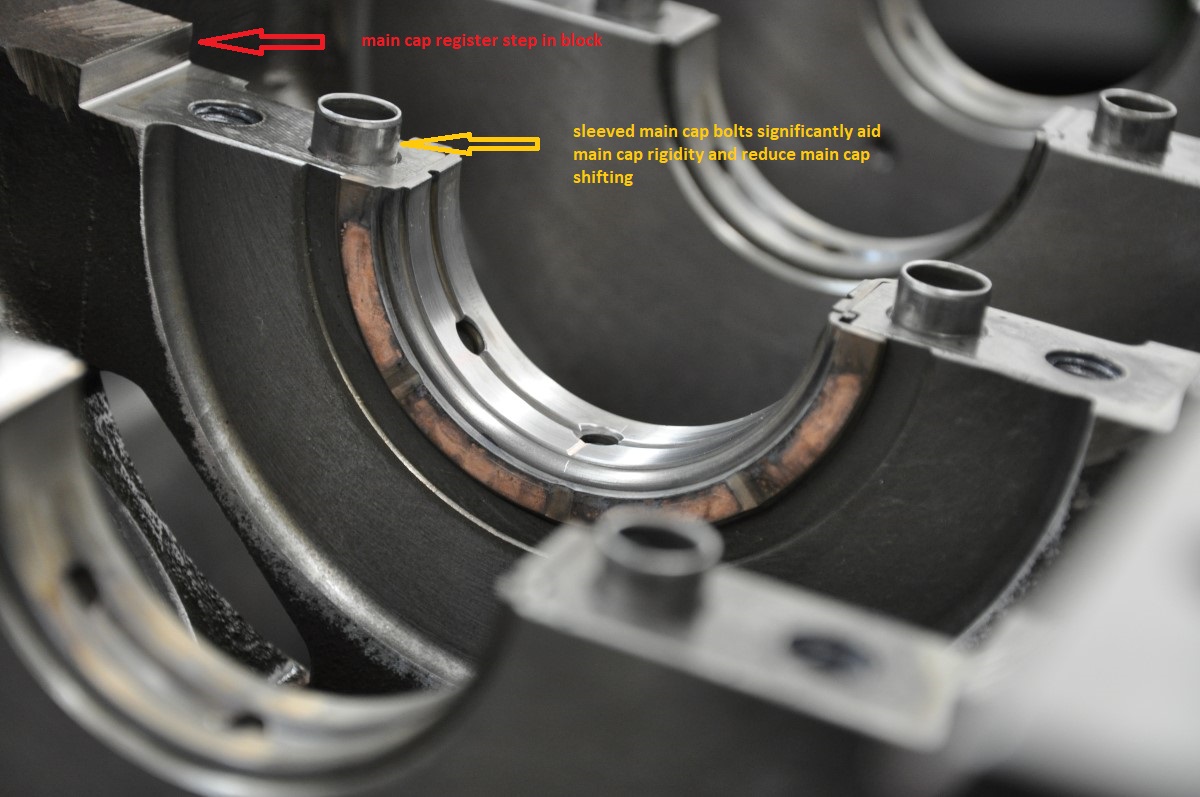

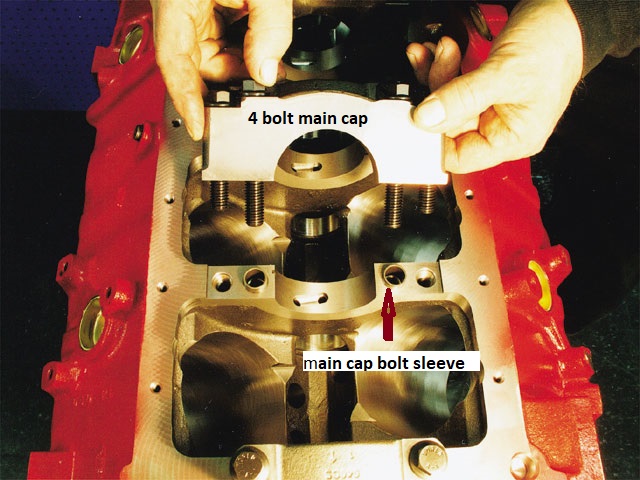

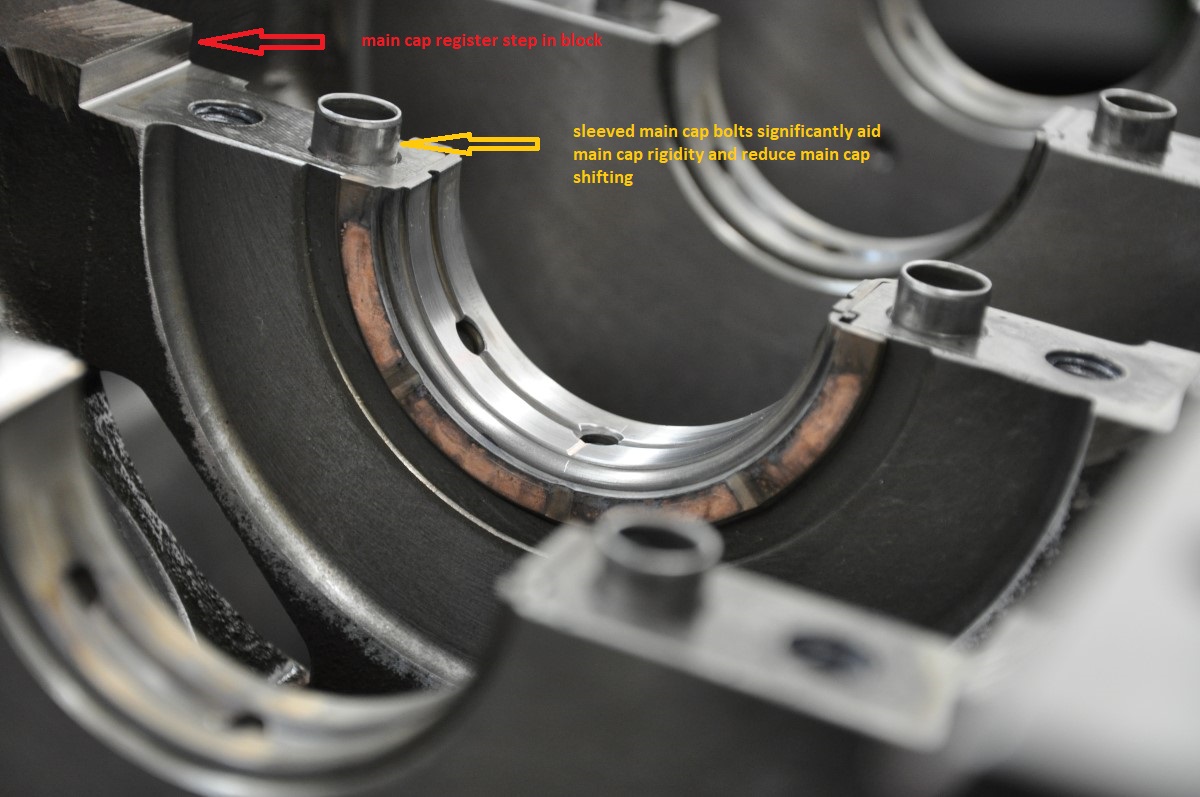

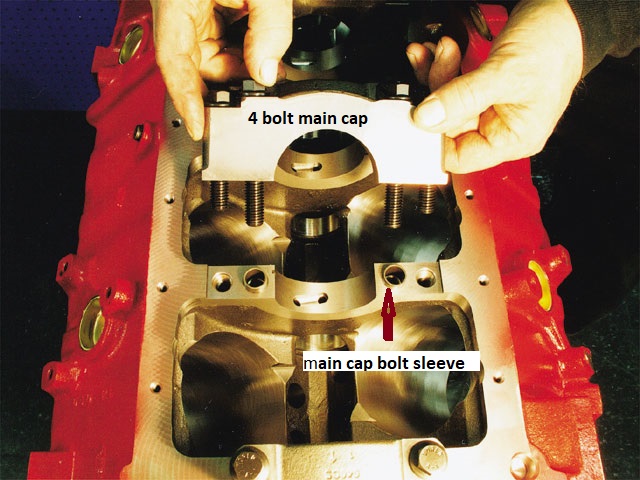

He pointed out to me that when the block was made, someone cut one side of the registers too wide. He said that

there were a couple ways to fix this.

He suggested to weld the registers and remill, along with hollow doweling the caps to the block, then line bore and hone . Which needed to be done anyway.

He prefers doweling because the registers can wear out and the caps can walk.

I also need to purchase a seal adapter because I have a 2 piece crank seal. $320

He said that because of the work needed to be done, this is why he was offering a $2800 block to me for $400

I paid the man and drank another coffee with him for about another hour before we loaded the block into my friends

truck.

I called my friend this morning and he said he went in early and rough bored the block and it is in the hot tank being cleaned already!

Out of respect for the man, I cannot show pictures or give alot of info about him, but....

He is a major R&D person who is contracted by A very well known automotive company!

I was in awe when I walked into his shop. I walked in feeling all of my 6' 1" frame, but left his shop feeling 2" tall!

I was very humbled, and grateful that I met this man.

Grumpy, you would like him! It was BBC heaven!

After I got over the overwhelmingness of the machinery, welders, tools and the layout of his (basically 30x60) shop, not including his office or the separate room for all grinding and sand blasting.

I could not help but notice a 272" dirt dragster sitting among another smaller dragster and the coolest sandrail

I have ever seen! There where BBC's on engine stands , some for customers and some where his. One N/A motor made 1600 HP.

There were trophies and pictures ( some with some VERY well known players) all over. All too cool!

We talked for about and hour to get to know each other better before we ventured over to the block he was offering

to me.

It is the race block I was hoping for! It has alot of surface powder rust on it but no scaling.

The block has never had a piston in it. It has to have alot of machining done to it. But In my case, there,s no costs.

It has the steel splayed main caps and studs.

He pointed out to me that when the block was made, someone cut one side of the registers too wide. He said that

there were a couple ways to fix this.

He suggested to weld the registers and remill, along with hollow doweling the caps to the block, then line bore and hone . Which needed to be done anyway.

He prefers doweling because the registers can wear out and the caps can walk.

I also need to purchase a seal adapter because I have a 2 piece crank seal. $320

He said that because of the work needed to be done, this is why he was offering a $2800 block to me for $400

I paid the man and drank another coffee with him for about another hour before we loaded the block into my friends

truck.

I called my friend this morning and he said he went in early and rough bored the block and it is in the hot tank being cleaned already!

it sounds like your search for a replacement block is bearing fruit,

Im sure someone reading your post is asking themselves .. what the hell is a register?

its the very shallow machined recess the main caps fit with a minor interference fit, in the blocks lower surface.

read this

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-18302

Im sure someone reading your post is asking themselves .. what the hell is a register?

its the very shallow machined recess the main caps fit with a minor interference fit, in the blocks lower surface.

read this

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-18302

Last edited:

Maniacmechanic1

solid fixture here in the forum

Nice Unforgiven !

Dowel Pinning the Main caps is a great way to locate.

Its How Pontiac V8 did it and Grumpy prefers himself on Chevy Blocks. Has pictures here how its done.

Come 1975 Pontiac was in the gas crisis crunch like everyone else. The Blocks went on weight savings diet.

They took out 40-50 lbs of iron.

In the Main webs.

Instead of using Solid 1/4" dowel pins like prior they used Split roll pins.

They had problems at times with Main webs cracking in the "557" Block raced hard in Trans Ams 1975-1977 so they tried Hollow dowel pins.

What ended up occurring the Hollow Dowel pins vibrated out and landed in the oil pan. Caps are drilled straight though 1/4" .No harm done, Main cap bolts are huge 1/2" and rear #5 at 9/16" diameter. So caps locked down tight.

Block 557 good for 500 Hp the less the better for longevity.

So from Pontiac end Solid Dowel Pins are better to use.

Dowel Pinning the Main caps is a great way to locate.

Its How Pontiac V8 did it and Grumpy prefers himself on Chevy Blocks. Has pictures here how its done.

Come 1975 Pontiac was in the gas crisis crunch like everyone else. The Blocks went on weight savings diet.

They took out 40-50 lbs of iron.

In the Main webs.

Instead of using Solid 1/4" dowel pins like prior they used Split roll pins.

They had problems at times with Main webs cracking in the "557" Block raced hard in Trans Ams 1975-1977 so they tried Hollow dowel pins.

What ended up occurring the Hollow Dowel pins vibrated out and landed in the oil pan. Caps are drilled straight though 1/4" .No harm done, Main cap bolts are huge 1/2" and rear #5 at 9/16" diameter. So caps locked down tight.

Block 557 good for 500 Hp the less the better for longevity.

So from Pontiac end Solid Dowel Pins are better to use.

Unforgiven

solid fixture here in the forum

Thanks Guys.

I am still in awe from what I witnessed!

LOL Sorry Grumpy.. I assumed most would know what a register is. Thank you for posting that link about it.

The caps were sitting over the studs when he showed them to me. The rough bore on the caps and block lined up nice as the cap was sitting in place. The outer splay bolts on the cap were in line . The cap sat tight against the passenger side register but there was a gap about .030 on the driver side.

I thanked Ryan for getting me in touch with this block. I also told him That I would give him another case of beer for scrapping my old block.

Although my machining if at no cost.... I told Ryan that I will be sending him a least a couple hundred for everything he has done.. I refuse to take advantage of him..If he won't take it, I told him his wife would be happy to except it!

I am still in awe from what I witnessed!

LOL Sorry Grumpy.. I assumed most would know what a register is. Thank you for posting that link about it.

The caps were sitting over the studs when he showed them to me. The rough bore on the caps and block lined up nice as the cap was sitting in place. The outer splay bolts on the cap were in line . The cap sat tight against the passenger side register but there was a gap about .030 on the driver side.

I thanked Ryan for getting me in touch with this block. I also told him That I would give him another case of beer for scrapping my old block.

Although my machining if at no cost.... I told Ryan that I will be sending him a least a couple hundred for everything he has done.. I refuse to take advantage of him..If he won't take it, I told him his wife would be happy to except it!

Unforgiven

solid fixture here in the forum

Unforgiven

solid fixture here in the forum

I sent the block to another shop to be bead blasted cause the sonic boiler did not do a very good job.

should have it back tomorrow.

Question: What are the bosses located on the main oil galley for ... I see some are tapped.

Mine are not. I was thinking that they might be for a spider? PIC is in my previous post.

Also I do not think this block is priority main oil . The galleys look like my old block.

I may be missing something but I needed to ask. I thought priority main oil had a galley that was more

rotated clockwise around the front cam bearing (if you will).?

NOW THE BIG QUESTION...Is it wise to just clear the registers and insert solid dowels for the caps.

Or would it be better to fix the registers to go along with the dowels. This is new territory for me so...

should have it back tomorrow.

Question: What are the bosses located on the main oil galley for ... I see some are tapped.

Mine are not. I was thinking that they might be for a spider? PIC is in my previous post.

Also I do not think this block is priority main oil . The galleys look like my old block.

I may be missing something but I needed to ask. I thought priority main oil had a galley that was more

rotated clockwise around the front cam bearing (if you will).?

NOW THE BIG QUESTION...Is it wise to just clear the registers and insert solid dowels for the caps.

Or would it be better to fix the registers to go along with the dowels. This is new territory for me so...

Maniacmechanic1

solid fixture here in the forum

Ideally you want to just align bore and hone so a Cloyes True Roller Race timing chain set .010" under can be used.

This is the foundation of all the engine the align bore for mains.

Done wrong the engine is junk for race use.

This is the foundation of all the engine the align bore for mains.

Done wrong the engine is junk for race use.