Ok .. I thought I would give another Update.

I did not get to make that oil pump tester. Being that the pump is new.. and it states it is a 60 psi pressure ,,I think it will be just fine. The original question was really about what the package said about that extra blue spring being used for H/P corvette pumps. I did not know that some of these cars used High Pressure.

Anyway ... the new BBC pump fit well and the new oil drive shaft measurements where around .060 play. I measured the pick up to pan and came up with 3/8"

I measured two different ways... I used a square and scale to measure the location of the pick up to the block,then I measured the depth of the pan.....The second method used was , I laid a piece of plastic on the pick up screen

and set a piece of silly putty on it. I then wiped some oil on the pan floor and set it in place on the block, and bolted it down with 4 bolts . Both ways showed a heavy 3/8"..

Sorry I did not get more pics of the procedure.

The Canton oil pan however did give me a little trouble... I had to trim out some off the top of the bulkhead above the trap door, to allow the nut clip that the windage tray bolts to,to be relocated forward about 1/8".

No Big deal.. Also had to open up a couple corner bolt hole abit bause they where binding on the stud threads.

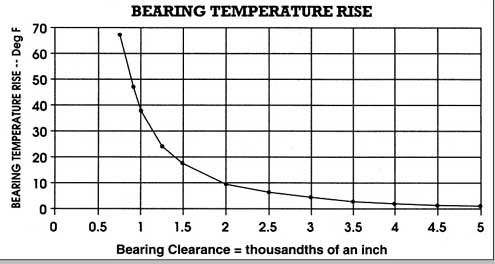

If you recall.. I was worried about the plastigage showing my rod bearings to only have .0015 clearance. I spent about 3 hours removing each one and mic'ing the crank, and using a dial bore gauge, I checked the

rod bearings ... I was correct in my thinking the plasigage had hardened and became brittle... I was getting a gauge reading of .0022-.0025 with and average of .0024 on most.

This rechecking made me feel alot better.

With the lower half passing inspection, I installed the oil pan and moved on to degree the cam in. It was within 1/2 degree of the card.

Next I made DAMN sure I had all the oil plugs in and installed the new block coolant drain valves ..

After all was good I installed a set of Cometic MLS gaskets .040 then set the heads over the studs and into place. Both heads torqued to 80 ftlb

Now if you recall back in the begining of this thread during the tear down.... I had made mention of how there seemed to be a ledge Between the heads and the intake.

Well ... I found it...

That motor musta felt like it was sucking a chocolate shake through a coffee straw!!!

Well. I did my best to take care of the issue.