Those tires would be 18.4 x 16.1 TITAN 's

They are agricultural tires normally found on Combine farm equipment.

They are around 44" tall ... and weigh 225lbs including the wheel.. Each.

It takes lots of torque to spin those puppies!

The suspension has to be modified to be able to withstand the abuse also.

I have custom designed and built the entire under carriage of this truck.

It uses 1410 U-Joints.

2 1/2 ton military axles

Transfer case is a special reverse front rotation matched with the axles also.

This is because the ring gear in the front axle is located on the opposite side in the center chunk

from any other axle. If you where to use a regular Transfer case ... the front axle would spin in reverse while the rear axle spins forward.

I have added shackles to each end of the front leafsprings for a softer ride. In order to do this, I had to fabricate a parallel 4 link control bar suspension.

The steering has been removed and replaced with a FULL hydraulic control system.

You can steer this beast with your little finger!

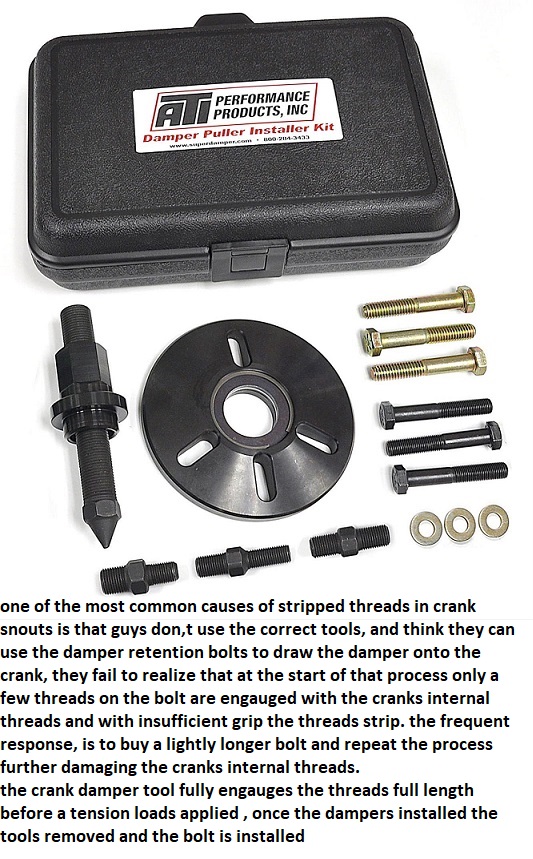

... I had rented a balancer install tool and installed the balancer ...so I thought!

... I had rented a balancer install tool and installed the balancer ...so I thought!