76GrayVette said:Right, so what all does the machine shop usually need to shave a block to a certain height?

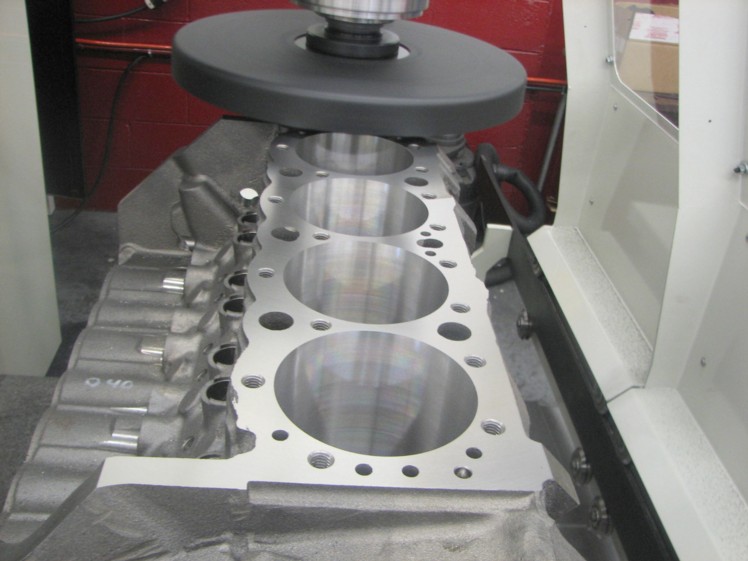

most shops line hone the mains then

indexing off the trued mains deck the block square and parallel too the crank center line axis

Just the block or do they need the crank and pistons as well?

NO

And does it matter that the cam bearings are already installed?

no not really but it would be best if you removed them, cleaned the block and all internal passages then replaced them, during that process to prevent machine debris crap being trapped in the block

viewtopic.php?f=54&t=1479

viewtopic.php?f=51&t=125

viewtopic.php?f=51&t=2919

viewtopic.php?f=51&t=5945

viewtopic.php?f=51&t=7646

viewtopic.php?f=51&t=7697

viewtopic.php?f=51&t=6162