- Home

- Forums

- Technical Articles/muscle cars

- American Muscle Cars

- Engine: Repairs , Modifications , Trouble Shooting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building Up A Blown Olds Motor for an "A/GS Gasser"

- Thread starter 2Loose

- Start date

2Loose

reliable source of info

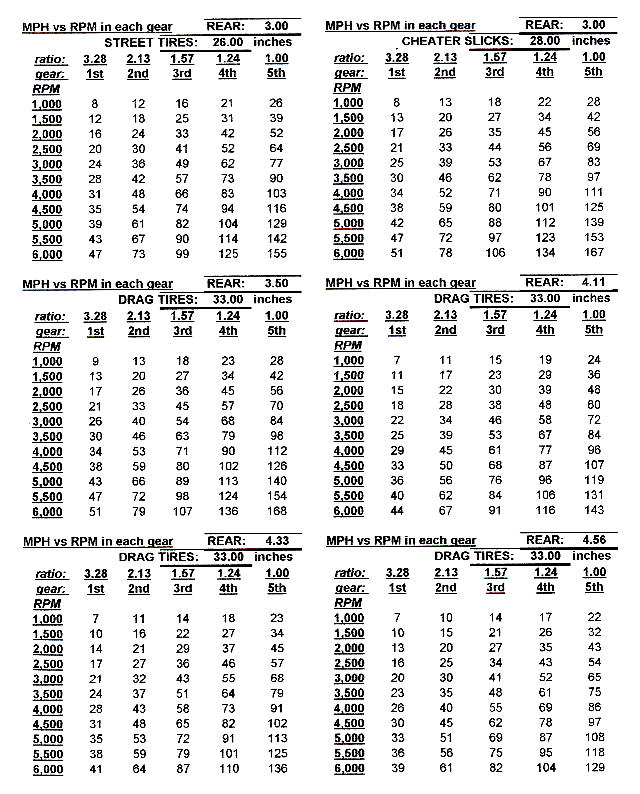

Only ran some Test and tune at the track in Feb. Running about 118 at 12.2. Slipping in each year. Not getting to the fifth gear my Doug Nash 5 sp has. Need more rear gear and better tires. Bought a set of Micky Thompson 33 inch tall by 10.5 wide, but think I need 4.11 gears. Have a set of 4.56 but they top out at 6000 at 128 in my excel spreadsheet. I would like a little more available at the top! 4.11 gears would give me 143 @ 6000 in 5th sez my Excel. Think I'll run my new 33" slicks w/ my 4.56 and see if I can coax the max out of her at the track in March. Not a good street gear though, when I slap the 28" street cheaters back on! I love the Nash 4+1 w/ the 3.0 rear and the 28" cheaters, it's an awsum combo on the street ( unless it rains!!??)....

Still havin' fun!

Aloha,

Willy

Still havin' fun!

Aloha,

Willy

8

87vette81big

Guest

How about 3.89 gears in yout Ford 9 inch rear?

Step above the 3.00 gearset installed now.

Below 4.11.

Richmond Gear makes the 3.89 gears.

I used 3.90 ,Richmonds in my 70 Ta. 27 inch tall rear tires.

Muncie 4 speed. 60 mph = 3,000 rpms in 4th high gear.

455 Pontiac built to redline at 7500 rpms.

Raced a 1969 L88 headed 427. Street race. I won.

Still able to cruise the highway at 80 mph.

BR

Step above the 3.00 gearset installed now.

Below 4.11.

Richmond Gear makes the 3.89 gears.

I used 3.90 ,Richmonds in my 70 Ta. 27 inch tall rear tires.

Muncie 4 speed. 60 mph = 3,000 rpms in 4th high gear.

455 Pontiac built to redline at 7500 rpms.

Raced a 1969 L88 headed 427. Street race. I won.

Still able to cruise the highway at 80 mph.

BR

2Loose

reliable source of info

weighed it today, took out the tool box and the tow hitch (they were in there when I ran the 12.2 at 118)....

and with me in it and 10 gal of gas it was an even 4,000 lbs. rotound lil' beastie I'd say....

Gonna take some power to get me into the low tens...

Actually with the 3.0 gears and the 28" tires, running that 118 at the weight (had the tool box and tow bar) of 4120 calcs out that I was pushing about 570 at the rear wheels, with the 4.56 gears and 33" slicks the same calcs look like I might actually get into the tens if I don't screw up along the way....

We shall see....

Aloha,

Willy

and with me in it and 10 gal of gas it was an even 4,000 lbs. rotound lil' beastie I'd say....

Gonna take some power to get me into the low tens...

Actually with the 3.0 gears and the 28" tires, running that 118 at the weight (had the tool box and tow bar) of 4120 calcs out that I was pushing about 570 at the rear wheels, with the 4.56 gears and 33" slicks the same calcs look like I might actually get into the tens if I don't screw up along the way....

We shall see....

Aloha,

Willy

8

87vette81big

Guest

If you can get race weight with you seated down to 3,000 to 3,200 lbs, it would be a big help to achieve your 10-second ET goals in 1/4 mile.

Lots of Fiberglass- Glasstech hoods & doors, bumpers, ect. Aluminum interior & strip out all luxury items. .

Pexiglass windows would help too loose weight.

Lots of Fiberglass- Glasstech hoods & doors, bumpers, ect. Aluminum interior & strip out all luxury items. .

Pexiglass windows would help too loose weight.

2Loose

reliable source of info

Yeah, I know you are right, just am reluctant to have to make a big bunch of changes right now....

But might just do that....

Am working on my '55 Bel Air hardtop right now, making a nice sbc 6 speed cruiser out of it, but hot rodding it quite a bit, when that's done, then might just decide to make the gasser a dedicated race car. But would probably put an automatic in, most likely a powerglide setup to run those tens, nobody else at our track is running a stick, just really hard to be competitive with a stick against the automatics, those guys running in the tens win or lose by hundredths of a second....

And I need to lose a lot of weight....

But might just do that....

Am working on my '55 Bel Air hardtop right now, making a nice sbc 6 speed cruiser out of it, but hot rodding it quite a bit, when that's done, then might just decide to make the gasser a dedicated race car. But would probably put an automatic in, most likely a powerglide setup to run those tens, nobody else at our track is running a stick, just really hard to be competitive with a stick against the automatics, those guys running in the tens win or lose by hundredths of a second....

And I need to lose a lot of weight....

Did someone say AutoMatic !!!

I cannot understand why a 2 speed Powerglide would be better than

3 speed or 4 speed automatic. Why would you run just a 2 speed

automatic ??? I can kinda understand when it's in dragster, but a

3000+ lb car.

Are you talking about class racing or bracket racing when you

say "win or lose by hundredths of a second...." ???

2Loose

reliable source of info

Good comments. The guys running power glides all love them, simple, tough, light, most cars at our track run them. We have 3 heads up classes, 12.90, 11.90, 10.90; 9.90 and faster is bracket racing, we are a small club, 13 and slower is street. About 200 cars in the 12.90 and faster. 11.90 and 10.90 run around 16 cars each on any Saturday, and we race generally 3rd Sat. Feb - Nov. I often watch two 11.90 cars cut a .50 lite at .58 and .59 then cross the line at 11.915 and 11.905, that's close racing! Seen it too many times! Or cross the line at 11.890 and 11.895, the lessor breakout wins. Heck, done that myself in '58 truck many times over the years in the 12.90 category. You guys know, side by side, you hit it, he hits it, you back off, he backs off, you hit it, etc etc...

My truck is a 12.50 rig, so I always played it to get as close to 12.90 as possible, and not break out more than the other guy!

The gasser was built the be a street driver on pump gas, drive to the track and run 11.90's, and maybe even 10.90's!

We'll see!

Willy

My truck is a 12.50 rig, so I always played it to get as close to 12.90 as possible, and not break out more than the other guy!

The gasser was built the be a street driver on pump gas, drive to the track and run 11.90's, and maybe even 10.90's!

We'll see!

Willy

8

87vette81big

Guest

To get down to the 10s while race weight is 4,000 lbs,

You need more horsepower. 1,000 to 1,200 horsepower at the flywheel.

It can be done with a stick shift.

Need a hotter camshaft. And crank up the blower boost. 15 psi or higher.

Switch to 116 octane race gas or methanol alcohol fuel highly advised.

Brian

You need more horsepower. 1,000 to 1,200 horsepower at the flywheel.

It can be done with a stick shift.

Need a hotter camshaft. And crank up the blower boost. 15 psi or higher.

Switch to 116 octane race gas or methanol alcohol fuel highly advised.

Brian

2Loose

reliable source of info

Present cam is pretty mild, was built for the street:

.507/.517

230/236 @ .050

hyd. roller lifters

1.6 rockers

aluminum heads have been reworked to flow better

plenty of room for more cam, 1.7 rockers, solid roller lifters

running 38/34 pulleys now for 12% overdrive on 6/71 and getting 7 lbs boost

running twin Holley HP 600's can upgrade those

now have the McLeod RXT twin disk clutch, it feels good, only slightly grabby on the street.

running detroit locker with 35 spline axles, over kill, but could put in a spool

thinking about it....

but next off season at the earliest, will just run it as is this year with 4.56 gears and the 33" tall slicks

in the meantime sorta lookng around for a light car, something cool to run....

Maybe...

Willy

.507/.517

230/236 @ .050

hyd. roller lifters

1.6 rockers

aluminum heads have been reworked to flow better

plenty of room for more cam, 1.7 rockers, solid roller lifters

running 38/34 pulleys now for 12% overdrive on 6/71 and getting 7 lbs boost

running twin Holley HP 600's can upgrade those

now have the McLeod RXT twin disk clutch, it feels good, only slightly grabby on the street.

running detroit locker with 35 spline axles, over kill, but could put in a spool

thinking about it....

but next off season at the earliest, will just run it as is this year with 4.56 gears and the 33" tall slicks

in the meantime sorta lookng around for a light car, something cool to run....

Maybe...

Willy

8

87vette81big

Guest

Your likely going to loose some streetabilty to get into the 10s.

I think you should consider a solid lifter roller cam profile.

You desire serious power. I am not a fan of hydraulic lifter cams above 6k rpm's.

Be wise to upgrade to a good full race spool. Alloy heat treated steel. 4k lb vehicle race weight.

Strange Engineering or Mark Williams. Wont break.

I think you should consider a solid lifter roller cam profile.

You desire serious power. I am not a fan of hydraulic lifter cams above 6k rpm's.

Be wise to upgrade to a good full race spool. Alloy heat treated steel. 4k lb vehicle race weight.

Strange Engineering or Mark Williams. Wont break.

2Loose

reliable source of info

My present setup is a 35 spline setup, and I have a solid MW 35 spline spool, am fitting 4.56 gears on it....

Gonna see what this present setup will do with the new tires and the 4.56's....

Shifting at 6k....

If I can run the number with what I got, hit each gear solid, should get a top end of 129 at 6k...

So the question is, can this motor do this in a quarter mile, and at what time? If I can get that fast, I should be in the tens....

Got the Mickey Thompson 33" tall tires, they hit the fender lips front and back, so am raising the fender openings and widening them in front...

Tight squeeze there....

OK, Let's whack 'em....

Tape it up and let's take a look....

Not bad, let's weld 'em in place....

Looking pretty good, need to fab some pieces for the gaps, finish welding everything up, grind, smooth, a little body filler here and there, not much needed though....

Aloha,

Willy

LINK to fender lip mod page....

Gonna see what this present setup will do with the new tires and the 4.56's....

Shifting at 6k....

If I can run the number with what I got, hit each gear solid, should get a top end of 129 at 6k...

So the question is, can this motor do this in a quarter mile, and at what time? If I can get that fast, I should be in the tens....

Got the Mickey Thompson 33" tall tires, they hit the fender lips front and back, so am raising the fender openings and widening them in front...

Tight squeeze there....

OK, Let's whack 'em....

Tape it up and let's take a look....

Not bad, let's weld 'em in place....

Looking pretty good, need to fab some pieces for the gaps, finish welding everything up, grind, smooth, a little body filler here and there, not much needed though....

Aloha,

Willy

LINK to fender lip mod page....

wow, does that series of pictures ever bring back memories of past projects.

I installed a dana 60 in a 1969 camaro, originally I was thinking the 31" tall slicks would fit...and that the DANA 60 would be a direct swap, needless to say the project evolved into a complete reworking of the rear suspension, finding out about how expensive custom made drive shafts were made, and how to cut off and move and re-weld brackets on a differential, drive shaft alignment, pinion angles, and a need to cut out and replace both the inner fender area and open up the area around the wheel wells, tub the rear wheel area, replace the fuel tank with a fuel cell, replace the fuel lines, cutting and fabricating and boxing the rear frame, re-carpet the interior, and eventually the need for a 6 point roll cage install, and how to do body work and a paint job.

at the time I had exactly zero skill with welding sheet metal, but over the next year I was forced to rapidly improve that lack of skills.

I was lucky in that because I had recently joined a local muscle car club and a few older guys were reasonably helpful, in being willing to teach me a few basics and show me how to correct screw-ups

related info in links

http://www.hotrod.com/howto/44559_pro_s ... e_section/

viewtopic.php?f=71&t=478&p=590&hilit=drive+shaft#p590

viewtopic.php?f=71&t=5083

viewtopic.php?f=71&t=4486

viewtopic.php?f=71&t=1934

viewtopic.php?f=60&t=3284

viewtopic.php?f=60&t=4233

viewtopic.php?f=60&t=4604

viewtopic.php?f=60&t=870

http://store.cyberweld.com/spec375cut.html

viewtopic.php?f=60&t=830

I installed a dana 60 in a 1969 camaro, originally I was thinking the 31" tall slicks would fit...and that the DANA 60 would be a direct swap, needless to say the project evolved into a complete reworking of the rear suspension, finding out about how expensive custom made drive shafts were made, and how to cut off and move and re-weld brackets on a differential, drive shaft alignment, pinion angles, and a need to cut out and replace both the inner fender area and open up the area around the wheel wells, tub the rear wheel area, replace the fuel tank with a fuel cell, replace the fuel lines, cutting and fabricating and boxing the rear frame, re-carpet the interior, and eventually the need for a 6 point roll cage install, and how to do body work and a paint job.

at the time I had exactly zero skill with welding sheet metal, but over the next year I was forced to rapidly improve that lack of skills.

I was lucky in that because I had recently joined a local muscle car club and a few older guys were reasonably helpful, in being willing to teach me a few basics and show me how to correct screw-ups

related info in links

http://www.hotrod.com/howto/44559_pro_s ... e_section/

viewtopic.php?f=71&t=478&p=590&hilit=drive+shaft#p590

viewtopic.php?f=71&t=5083

viewtopic.php?f=71&t=4486

viewtopic.php?f=71&t=1934

viewtopic.php?f=60&t=3284

viewtopic.php?f=60&t=4233

viewtopic.php?f=60&t=4604

viewtopic.php?f=60&t=870

http://store.cyberweld.com/spec375cut.html

viewtopic.php?f=60&t=830

2Loose

reliable source of info

4 1/2" Dewalt with a thin cutoff blade, do lots of little cuts to keep from heating up the metal. I use a sharpened screwdriver to mark the cuts, scratching it in the paint to get a fine line, and very carefully plunge cut into the sheet metal, jumping around and spreading it over time to keep the heat under control. If bare metal, spray some rattle can flat black on to scratch the marks in. Same with the welding, small spots, spread around, touching with my hand to make sure it stays cool. I have a small Lincoln 100 amp, 120 volt mig, run 0.023" wire, use a ER70s-6. There is a new wire out, a ER70s-7 that is supposed to be a little softer, grinds down and smooths out easier, and the spot welds lay a little flatter, but I have not found any of that locally as yet.

Willy

2Loose

reliable source of info

Ran some numbers on an Excel spreadsheet.

RPM vs MPH for various tire diameters and rear differential gears for my '55 gasser:

The first two data sets show my current street setup with 3.00 gears (tried 3.50, I like the feel of the 3.00 set on the street better....), running either my 26" tall street tires or my 28" tall DOT cheater slicks. The cheater slicks are what I ran at the track when I got the 12.20 at 118 mph, crossing the line in 4th at somewhere around 5000 rpm plus...

Ran the other four data sets with the 33" tall Mickey Thompsons, using my 3.50, 4.11, 4.33 and 4.56 gear sets. My current rear end is a 35 spline 9" setup w/ Detroit Locker I got from a guy in Honolulu, after they shut down the drag strip over there, a lot of race parts suddenly became "for sale" when that happened...

It takes me slightly over an hour to swap out a 9" third member pumpkin if I don't waste any time, and I have a 35 spline spool, so will set up a spare third member pumpkin I have with the 4.56 spool and run that at the track. Shifting at 6,000 and crossing the line in 5th at 6,000, if I can make the power, hit the shifts, not spin coming off the line, there is a potential for a high 10 second run at 129.

Ya just never know until ya try....

Aloha,

Willy

LINK: Added the spreadsheet to my web page...

RPM vs MPH for various tire diameters and rear differential gears for my '55 gasser:

The first two data sets show my current street setup with 3.00 gears (tried 3.50, I like the feel of the 3.00 set on the street better....), running either my 26" tall street tires or my 28" tall DOT cheater slicks. The cheater slicks are what I ran at the track when I got the 12.20 at 118 mph, crossing the line in 4th at somewhere around 5000 rpm plus...

Ran the other four data sets with the 33" tall Mickey Thompsons, using my 3.50, 4.11, 4.33 and 4.56 gear sets. My current rear end is a 35 spline 9" setup w/ Detroit Locker I got from a guy in Honolulu, after they shut down the drag strip over there, a lot of race parts suddenly became "for sale" when that happened...

It takes me slightly over an hour to swap out a 9" third member pumpkin if I don't waste any time, and I have a 35 spline spool, so will set up a spare third member pumpkin I have with the 4.56 spool and run that at the track. Shifting at 6,000 and crossing the line in 5th at 6,000, if I can make the power, hit the shifts, not spin coming off the line, there is a potential for a high 10 second run at 129.

Ya just never know until ya try....

Aloha,

Willy

LINK: Added the spreadsheet to my web page...

2Loose

reliable source of info

It's been slower than I thought getting those relocated wheel well openings finished! Grinding down the welds I somehow got a piece of rusty metal in my eye! Even while wearing safety glasses! Had to go to the Dr. and have it removed, they actually had to scrape out the rust particles! Now at home with a very sore eye! Doesn't look good to race tomorrow night, can only see out of one eye at the moment! Oh well, there's always the April races....

Willy

Willy

sorry to hear you got injured I know as we get older many of us need glasses to see details in dim light or up close and wearing safety goggles becomes a BIG P.I.T.A. as they either don,t fit or you can,t wear two sets of glasses or goggles fog up.

clear face shields work fairly well, screen shield also have uses and don,t fog up, both are much cheaper than doctor care

lighted safety glasses and head band head lamps help at times

http://www.harborfreight.com/five-led-m ... 93549.html

http://www.jegs.com/i/JEGS/551/LSG279760JEG/10002/-1

http://www.harborfreight.com/adjustable ... 46526.html

http://www.harborfreight.com/mesh-face- ... 97010.html

clear face shields work fairly well, screen shield also have uses and don,t fog up, both are much cheaper than doctor care

lighted safety glasses and head band head lamps help at times

http://www.harborfreight.com/five-led-m ... 93549.html

http://www.jegs.com/i/JEGS/551/LSG279760JEG/10002/-1

http://www.harborfreight.com/adjustable ... 46526.html

http://www.harborfreight.com/mesh-face- ... 97010.html