Maniacmechanic1

solid fixture here in the forum

Yes Rick.I'm going to run a compression test first, since I'm already setup. I'm not ready to jump in and change the intake manifold

gaskets, I went to great pains cleaning 15-20 times, getting the sealer just the right thickness on the rails front and back.

Grumpy says its a quick and easy task, but it's an all day job for me with my OCD.

Charging the battery with my trickle charger at 4 amps before the compression test.

But something like that is on my mind, what should I expect with WD40, will it rev up some if there

is a vacuum leak?

I just tried another carburetor that has been on the shelf for 30 years. I did spray carb cleaner with the

red tube stuck into the air bleeds and blew it out with air. Filled the bowls thru the vent up to the site plug

and made sure the pump worked. Since my fuel lines coming in will not connect, I filled the bowls again

thru the vent up to the site plug. It should run long enough to see a difference if the carburetor is the

problem.

No difference to even worse, therefore that's why I'm getting ready to do a compression test. It back fires

thru the carburetor during many of the different tests, wondering if I have a intake valve staying open. I

noticed and so did Brian that that fuel cloud above the carburetor in the video just as the engine starts.

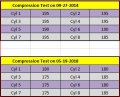

View attachment 9835

Spend Sunday Diagnosing.

I agree do a compression test.

Plausible an intake valve is not seating and staying open.

Readjust the offending cylinder valves.

Retest.

I Don't like that Fuel Standoff.

Should only be present On Race Cars with full drag race cams with 100-120 degrees valve overlap.

Idle speeds on such cams are 2000-2500 rpms.