I don't even have the rear cam plug in the block if that's what your are thinking.grumpyvette said:are you sure theres nothing like compacted grease behind the cam keeping it from going a bit further?

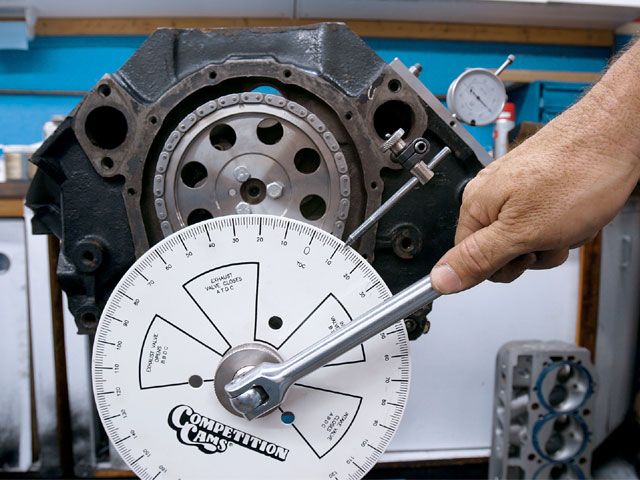

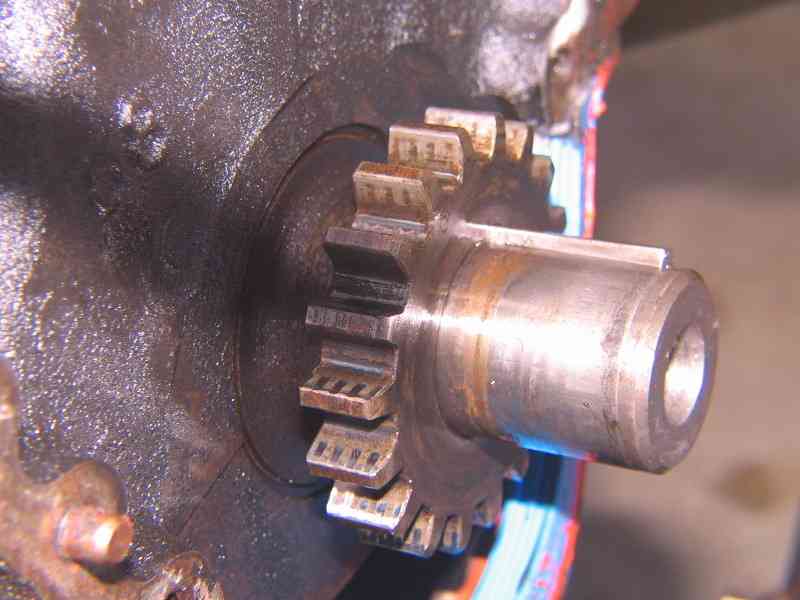

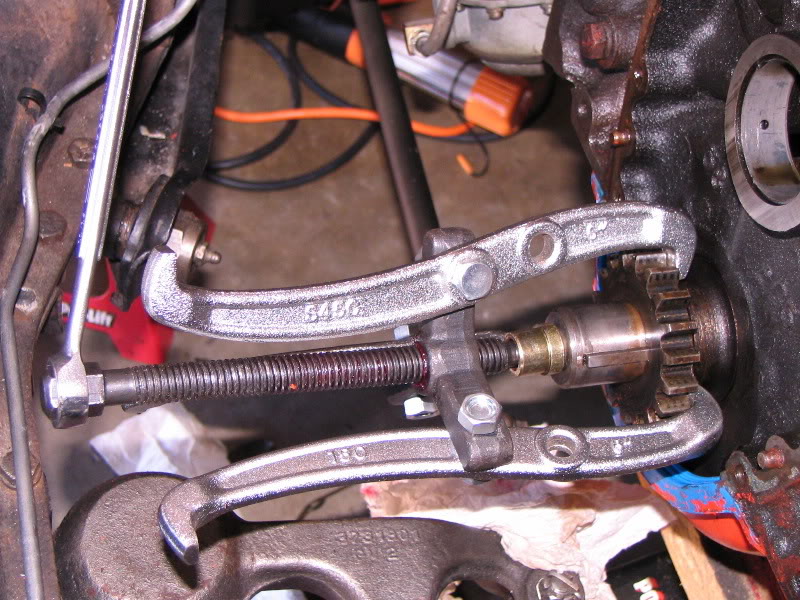

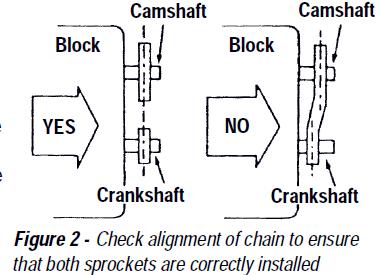

FYI, this camshaft is using the thrust plate at the front, behind the timing gear. End play for the camshaft is .004", what should it be ???

Last edited: