Indycars said:

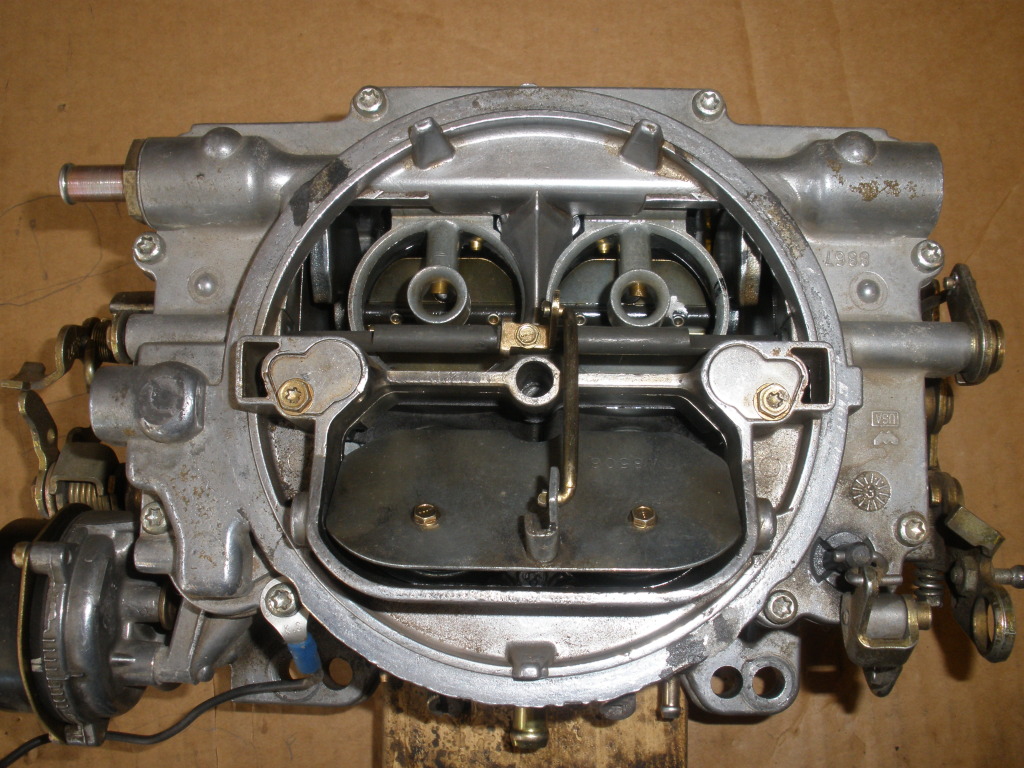

Your comments make me wonder .... what orifices change with carburetor size???

Other than the venturis ? I'm going on memory tonight, but I think the IAB's were

.078 inches for my 750 Speed Demon carburetor.

Some variation is to be expected based on engine differences .....

camshaft parameters, bore, stroke ...etc.

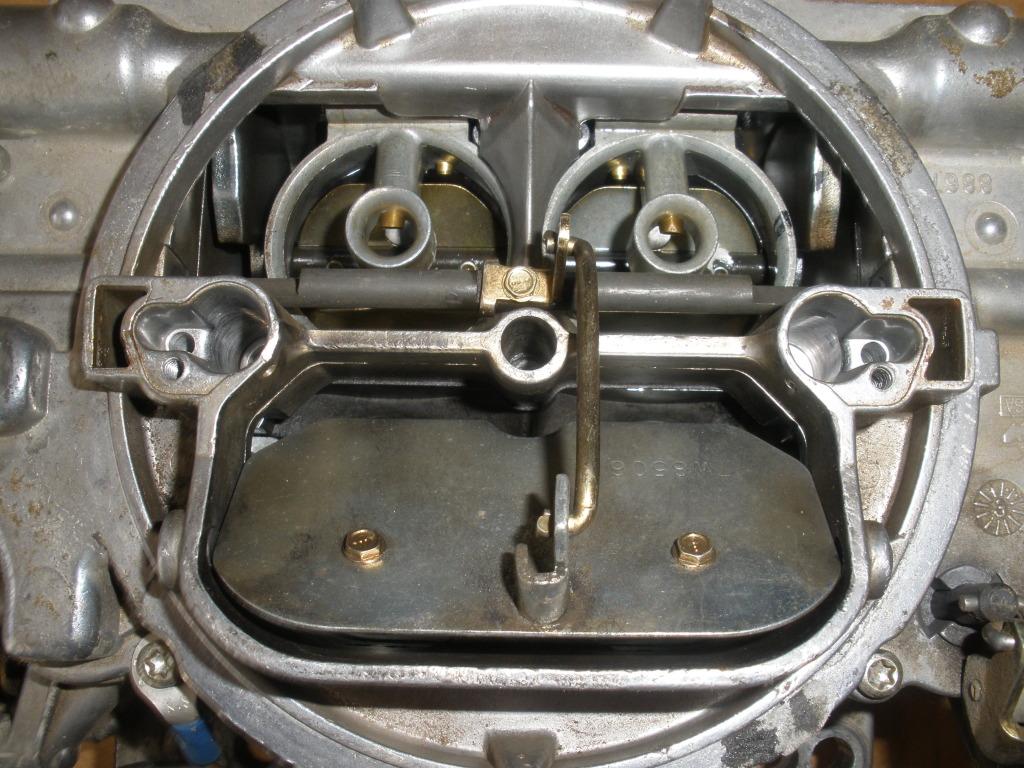

If I had gone with the 8-32 in the air bleeds (IAB & HSAB), then I would have had a

much better chance at recovery from my mistakes in the ONE IAB where I messed up.

The HSAB and IFR change slightly based on carb size.

https://www.demoncarbs.com/Tech/SpecCharts.asp

If memory serves me correctly, the main problems I had with my setup were:

- rich tip in off idle.

- Transition circuit shut off too soon.

- Mains did not come online soon enough.

- A not so flat main fuel curve from too much emulsion.

Now keep in mind, carbs are a bit of science and witchcraft. I found that using other folks experiences as a guide is very helpful but

just because someone who has a similar build as you do drills out their IFR to .035"and found nirvana dosen't mean the same will work for you. Make one change at a time and log the results. These things are balanced, meaning if you make one change, you will probably need to make a change in another area of the carb. It's tedious but you will learn a lot about carburetion.

-