You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Planning a new 383 build that is now going to be a 400

- Thread starter busterrm

- Start date

busterrm

solid fixture here in the forum

The old lines are all mangled and such, so I thought while I have the open area when the engine bay is empty,I would replace them, and that will be when I do the cooler placement.Indycars said:

Why the new trans cooling lines, was something wrong with the originals?

Are you still looking for a TH350 case for mockup?

Yes, I am still looking for a TH 350 case, haven't found one down here yet.

busterrm

solid fixture here in the forum

Okay, this is how I did it. First I read that link you sent Grumpy. But the measuring part I thought why hold a level when I could mock up a measuring device with flatbar. Here it is:

Then came the actual measuring, I ended up with a distance of 3 7/8 inches or radius, the picture shows it without the pan gasket, so the gap between the rod cap screws is a little larger.

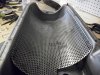

I tossed the poster board template, I got kinda frustrated with it a lot. But this is the windage screen itself.

Next I mocked up the front and rear piston/rod assemblies, and used the pan gasket and put 1/4 flatbar on top, for the 1/4 inch I figured in to the equation. If you look there is about 1/8-3/16 clearance between rod capscrews and the screen. My exact measurement came up at just shy of 3/16 inch clearance.

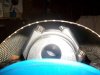

Here are two pictures of how the windage screen will look in the oil pan.

If you look at the first picture you can see the notch I cut in the screen allows for insertion of the dipstick.

Then came the actual measuring, I ended up with a distance of 3 7/8 inches or radius, the picture shows it without the pan gasket, so the gap between the rod cap screws is a little larger.

I tossed the poster board template, I got kinda frustrated with it a lot. But this is the windage screen itself.

Next I mocked up the front and rear piston/rod assemblies, and used the pan gasket and put 1/4 flatbar on top, for the 1/4 inch I figured in to the equation. If you look there is about 1/8-3/16 clearance between rod capscrews and the screen. My exact measurement came up at just shy of 3/16 inch clearance.

Here are two pictures of how the windage screen will look in the oil pan.

If you look at the first picture you can see the notch I cut in the screen allows for insertion of the dipstick.

Attachments

thanks for posting some really informative pictures that are sure to help others!

you look to have done an exceptionally clean, and well thought thru job, of fabricating that windage screen,

FOR A HOBBYIST TO TAKE THE EFFORT TO EVEN BUILD A DECENT WINDAGE SCREEN SHOWS WELL ABOVE AVERAGE SKILLS

now all you need is a good solid and secure way to keep it solidly locked into its desired location, obviously welding it into the oil pan permanently in place, after very carefully verifying clearances with the rotating assembly arc is one option,, and certainly the simplest , of course welding in mount brackets, on the under side of the windage screen and possibly welding in bolts or studs in the pan to be used with nyloc nuts or safety lock wire is also an option you might want to consider, to make cleaning under the windage screen easier.

looking at that windage screen I'd think it will be every bit as effective as any you could purchase and probably better quality THAN MANY Ive seen.

keep in mind this windage screen, is not going to result in big horse power gains but what it usually does do is , it makes the oil supply to the sump and oil pump and bearings and the pressure they see far more consistent, which is good for long term durability as long as you keep the oil clean and filters changed regularly, remember to set the oil pump pick-up clearance to the oil pan floor at 3/8'-1/2" and braze the pick-up to the pump.

related threads

viewtopic.php?f=50&t=4306&p=11353&hilit=+safety+wire#p11353

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=1800

viewtopic.php?f=54&t=65

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=2187

you look to have done an exceptionally clean, and well thought thru job, of fabricating that windage screen,

FOR A HOBBYIST TO TAKE THE EFFORT TO EVEN BUILD A DECENT WINDAGE SCREEN SHOWS WELL ABOVE AVERAGE SKILLS

now all you need is a good solid and secure way to keep it solidly locked into its desired location, obviously welding it into the oil pan permanently in place, after very carefully verifying clearances with the rotating assembly arc is one option,, and certainly the simplest , of course welding in mount brackets, on the under side of the windage screen and possibly welding in bolts or studs in the pan to be used with nyloc nuts or safety lock wire is also an option you might want to consider, to make cleaning under the windage screen easier.

looking at that windage screen I'd think it will be every bit as effective as any you could purchase and probably better quality THAN MANY Ive seen.

keep in mind this windage screen, is not going to result in big horse power gains but what it usually does do is , it makes the oil supply to the sump and oil pump and bearings and the pressure they see far more consistent, which is good for long term durability as long as you keep the oil clean and filters changed regularly, remember to set the oil pump pick-up clearance to the oil pan floor at 3/8'-1/2" and braze the pick-up to the pump.

related threads

viewtopic.php?f=50&t=4306&p=11353&hilit=+safety+wire#p11353

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=1800

viewtopic.php?f=54&t=65

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=2187

busterrm

solid fixture here in the forum

My new tranny lines and fuel pump roller pushrod arrived and I am now caught up on parts, until I order the carb and pushrods. I got the windage screen tig welded into place and it looks great. The oil pan picture is dark, with the stainless windage screen the flash blinded the view of the welds, so I took them with the flash off.

With carbon steel and stainless the weld metal used is 309 for the union of the two different parent metals, I got a good friend at work to do the tig welding for me, I can tig but carbon and stainless I wanted it done right.

The Dart block has a blind hole in the front mount position, so I will have to drill a 5/16 hole and tap the hole deeper to accommodate the set screw pin to hold the roller pushrod in correct orientation to the camshaft.

I will have to do some modification to the tranny lines when I install the aftermarket tranny fluid cooler

With carbon steel and stainless the weld metal used is 309 for the union of the two different parent metals, I got a good friend at work to do the tig welding for me, I can tig but carbon and stainless I wanted it done right.

The Dart block has a blind hole in the front mount position, so I will have to drill a 5/16 hole and tap the hole deeper to accommodate the set screw pin to hold the roller pushrod in correct orientation to the camshaft.

I will have to do some modification to the tranny lines when I install the aftermarket tranny fluid cooler

Attachments

busterrm

solid fixture here in the forum

I plan on getting the pickup tube tig welded to the body of the oil pump at work in the near future. As promised by the seller of the pan the pickup screen is about 7/16 off the floor of the oil pan, I will do the process again with the modeling clay and illustrate what it looks like.

busterrm said:I will have to do some modification to the tranny lines when I install the aftermarket tranny fluid cooler

I went back 7-8 pages couldn't find where you said if you were going to use

both coolers or just the aftermarket cooler. Which way are you going?

I have a nice Rigid 37° flaring tool if you want to use some AN fittings. I

also have a very nice tubing bender if needed.

A very nice and sturdy looking windage screen. I wonder how many are

built from too light of material and end up vibrating badly.

Attachments

busterrm

solid fixture here in the forum

I am going to run the aftermarket cooler then into the radiator also, not sure what route I am going to go with it. I will either buy a cooler with a fan and then have to get a deep pan to put a sensor in, or get one of the small coolers and mount it behind the front grill. This windage screen is 14 gauge stainless perf, and I rolled it at work to get the exact radius right. So its .078 or just shy of 5/64 thk, so I don't think its going to vibrate at all, the guy that did the tig welding is a great welder and he did a great job for me. I was there while he welded it and kept spraying cool water on it after each weld to keep it from distorting. I think it turned out pretty good.Indycars said:busterrm said:I will have to do some modification to the tranny lines when I install the aftermarket tranny fluid cooler

I went back 7-8 pages couldn't find where you said if you were going to use

both coolers or just the aftermarket cooler. Which way are you going?

I have a nice Rigid 37° flaring tool if you want to use some AN fittings. I

also have a very nice tubing bender if needed.

A very nice and sturdy looking windage screen. I wonder how many are

built from too light of material and end up vibrating badly.

busterrm said:Time for more parts and tools! I am going to order the alternator and power steering pump brackets, crank socket, balancer install tool, and radiator support rubbers. looks like about 190 bux this time, won't hurt too bad.

viewtopic.php?f=50&t=9344&p=33901#p33901

viewtopic.php?f=50&t=902&p=1463&hilit=balancer+puller#p1463

viewtopic.php?f=52&t=1759&p=4441&hilit=cam+degree+tools#p4441

busterrm

solid fixture here in the forum

Okay Guys, I need some opinions! I am starting to look at Carbs, I am considering the Holley Street Avenger 770, Summit has this one, with a dual feed fuel line and fuel pressure gauge. That price is about max for what I can afford!

http://www.summitracing.com/parts/cmb-03-0253/overview/

What do you guys think and/or any suggestions?

http://www.summitracing.com/parts/cmb-03-0253/overview/

What do you guys think and/or any suggestions?

busterrm

solid fixture here in the forum

Hey Guys, I am up in OK City, Rick is fixing my laptop pc so I can stop running back and forth from garage to pc in house to post pics. I am going to use the laptop in the garage to catalog my progress on my build.

Interesting Sunday afternoon drive, I ride to Ok City to pick up a TH 350 case, I couldn't find one in WF that any shop would let go of for less than 150 bux. So my friend Indycars finds one for 50 bux here in the city. Anyway Rick is also fixing my laptop. Well, I have been wanting to go for a ride in the T Bucket also. Well, kinda funny, ride to Ok City, load the tranny case, laptop is fixing, and we go for a ride, let me tell ya guys Rick has a winner in the T bucket. My khaki shorts almost became color fast let me tell ya!

Interesting Sunday afternoon drive, I ride to Ok City to pick up a TH 350 case, I couldn't find one in WF that any shop would let go of for less than 150 bux. So my friend Indycars finds one for 50 bux here in the city. Anyway Rick is also fixing my laptop. Well, I have been wanting to go for a ride in the T Bucket also. Well, kinda funny, ride to Ok City, load the tranny case, laptop is fixing, and we go for a ride, let me tell ya guys Rick has a winner in the T bucket. My khaki shorts almost became color fast let me tell ya!

busterrm

solid fixture here in the forum

Hey Rick, I got the router hooked up and am getting a weak signal to the laptop, I am going to run a direct Ethernet cable from the router to the garage. I took the measurements and a 125 ft cable will work, I am going to get a outdoor cable for it also.

8

87vette81big

Guest

A Holley HP SERIES CARBURATOR With Mechanical Secondaries & Adjustable Air Bleeds & 4-corner idle system is the Only style Holley to use on a True Performance engine .

4150.

You get what you pay for Bob.

BLP Bo Laws the Best. My Holley.

What feels fast & what actually is fast at the Race Track in 1/4 mile is often Night & Day difference.

Rick needs to tune at the Drag Strip.

10's & 9's the Goal.

His Hometown competition is Faster still.

4150.

You get what you pay for Bob.

BLP Bo Laws the Best. My Holley.

What feels fast & what actually is fast at the Race Track in 1/4 mile is often Night & Day difference.

Rick needs to tune at the Drag Strip.

10's & 9's the Goal.

His Hometown competition is Faster still.

busterrm said:Hey Rick, I got the router hooked up and am getting a weak signal to the laptop, I am going to run a direct Ethernet cable from the router to the garage. I took the measurements and a 125 ft cable will work, I am going to get a outdoor cable for it also.

I have a 1000 feet of Cat 6 cable and ends that I can crimp on. I'm never going

to use it all if you need ......

Where is it located? Can you run a cable to the back of the house and located

the wireless router there?

busterrm

solid fixture here in the forum

What I was going to do is run it out one of the windows in the living room and along the top of the house and to the gable of the garage. I have the cable on its way already. wasn't much like 30 bux, its a outdoor cable. Direct line my router is about 100 foot from the laptop, so I am thinking thats the reason for the weak signal. Its so weak the laptop can even find the IP address.

why would you hook a LIGHTING ROD TO YOUR LAPTOP!

why would you hook a LIGHTING ROD TO YOUR LAPTOP!