This week, it's going to be in the teens at night again. So I drained the water out of the block so

there was no chance of it freezing and cracking the block before I get this thing running again.

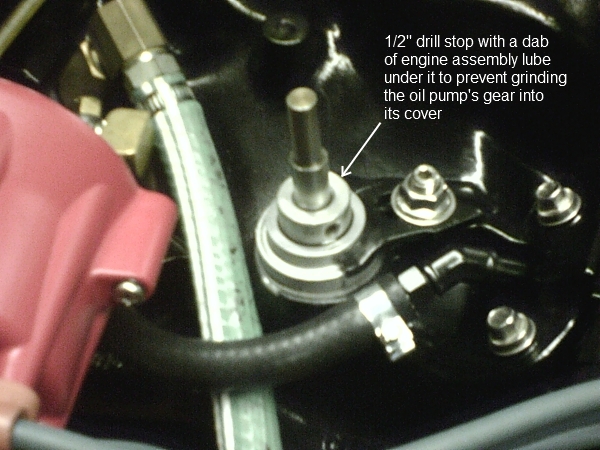

Because I wanted to rotate the crank while running the oil pump to flush the passages and bearings

with diesel fuel, I added a drill stop to my preluber so that there would no downward pressure on

the oil pump gear, grinding into the oil pump cover. I put a dab of assembly lube between the stop

and the top of the distributor.

I poured a little less than 2 gallons of light green diesel fuel into the crankcase.

At this point, there is no camshaft or lifters in the block. And I installed a cheap NAPA oil filter on the block.

It's the same ones I use on my parts washer - the cleaning solution stays clean for years.

I hung a rag over the timing cover area because I figured that there would be a little bit of splash there. I slowly

started the drill motor and increased the speed and saw almost 40 psi on the oil gauge. I expected minimal pressure

because of the huge leaks from no lifters or camshaft.

Then I noticed the not-so-small puddle of diesel fuel forming on the garage floor at the front of the

engine. I raised the the front of the engine with my floor jack trying to help the diesel to flow back into the pan.

NOPE. I installed the old camshaft and tried it again. BETTER, but diesel still spilling onto the floor. The diesel is

leaking out between the cam and front cam bearing. I made a curved "funnel" to direct the diesel to the oil pan at

the front main bearing and held it in place with a bungee cord. NOW WE"RE GETTING SOMEWHERE. Now

there was the matter of that small hole in the cam gear face to plug. I sanded a pushpin down to fit the hole (.040").

Unplugged, it probably would have shot the diesel 40 feet.

So now I'm finally ready to run the oil pump and flush the passages and bearings. I ran the oil pump and while I'm

watching for spillage, I noticed something very interesting. I saw the diesel leaking out from around the front main

bearing, just like the cam, as expected. What surprised me was the 2 streams of diesel shooting out from the parting

lines of the front main bearing, both squirting directly at the crank gear.

If the same thing happens with the engine oil, then there is no need for any extra

oiling holes for the timing set. I might get yelled at for making that statement.