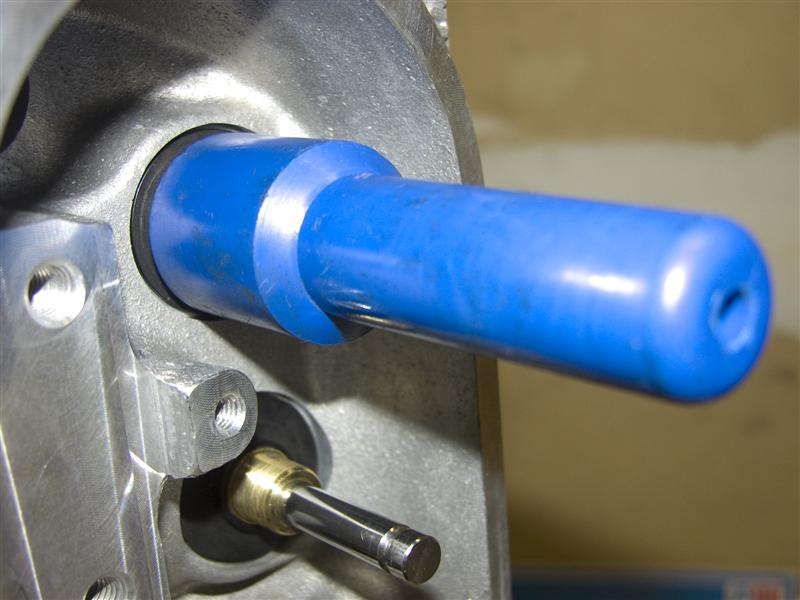

I'm using the actual pump that going in the motor.grumpyvette said:Im reasonably sure it could be made to function but holding the pump and running the drill and reading the gauge at the same time might be a problem and Im assuming your using a second pump body as the test tool so the bye-pass clearances might be slightly different than the actual pump and the component clearances being different the results you'll be getting will be very slightly different "

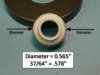

There wasn't much room to get three holes in the space required and the only copper washers I had

were 3/8". So I used 1/8" pipe thread and then adapted it to the 1/4" pipe for the gauge. The 3rd hole

was 1/16", the smallest drill bit I had.

The first time I tested, when the solvent hit the bleed hole it looked like an injector nozzle, nearly

reaching the 8' ceiling. I was able to hold my finger over the hole when I tested with NO spacer. But

when I added the first spacer it was too much, so I put a sheet metal screw in the hole, it still would

bleed air since it was not a good seal.

Like you mentioned it was hard to get a good reading, but the difference were obvious between

each of the different tests. I didn't need good accuracy in this situation.

1st test with NO spacer - ..... 70 psi

2nd test with one spacer - ...100 psi

3rd test with two spacers - ..150 psi

I sure am glad I posted that picture with the spacer sleeves and you questioned whether that was right. I have

to wonder how long it would have taken to trouble shoot this one with the motor in the car. But one nice thing

about this car, there is NOTHING under the oil pan. It would be very easy to drop the pan for a look.

.

Last edited: