RELATED THREADS AND LINKED INFO

viewtopic.php?f=50&t=6255&p=21695&hilit=cleaning+parts#p21695

viewtopic.php?f=50&t=6847&p=22254&hilit=parts+washer#p22254

viewtopic.php?f=50&t=6255&p=19681&hilit=parts+washer#p19681

viewtopic.php?f=27&t=2886&p=12701&hilit=parts+washer#p12701

There are an awful lot of greasy parts in the world. Cheap parts washers barely filter the cleaning chemicals and recirculate a solution of sludge. The nice parts cleaners have a filtering system, but cost hundreds of dollars. This is a simple design for a filtering system that will make up most of the gap between your cheap parts washer and the professional units without stressing your wallet.

The $50–$100 parts washers on the market consist of a tank, a pump, a hose and a brush. Only a small piece of gauze serves as a filter, and it is almost totally ineffective. In the parts washer of the $1,000 price range, the used cleaning solution drains into a barrel on which the parts washer sits. Cleaning solution is drawn through a filter element before recirculating back through the parts-washer brush. The filtration makes all the difference. So this design swaps the crappy gauze filter for an automotive oil filter and a remote oil-filter mount, mimicing the high-end mode of operation for around $75.

Ingredients:

(If you would prefer to purchase the parts for this conversion all at once, I've put together parts washer filter kits available in the TE eBay store.)

A cheap parts washer. Presumably you already have this. I used mine, a well used Northern Tool 20-gallon model.

Perma Cool model 1213 remote oil filter mount. Jegs p/n 771-1213 $15.99

Chevy 2 Quart Oil Filter. Napa Oil filter 21794 or equivalent. $9.16

Around 10 feet of 3/8" Air, Water, and Oil hose. McMaster p/n 5138K64. $0.84/ft

Pipe to 3/8"-hose adapter suitable for the outlet of the existing parts washer. Most of these, including mine, are 1/4" NPT, which is McMaster p/n 5346K18. $9.19/10

1/2" NPT to 3/8" hose adapter. McMaster p/n 5346K21. $11.07/5

Hose Clamps for 11/16" OD hose. McMaster p/n 5388K16. $5.28/box

Rubber Grommets for 11/16" OD hose. McMaster p/n 9600K55. $5.89/25

4x 5/16" NC bolts 1" long, 4x 5/16" washers, and 4x 5/16" NC nuts

Parts Washer Filter Holes: Vin Marshall

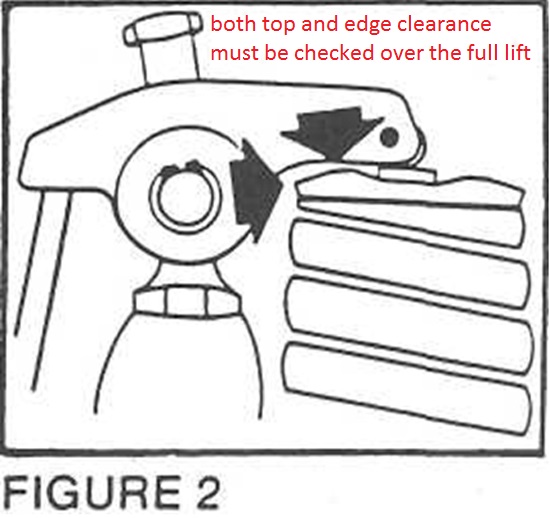

First, we'll need two holes in the side of the parts-washer tank through which the hose can pass. Drill these above the normal fluid level of the tank so that a perfect seal is slightly less important. The outer diameter of your grommets will determine the size of these holes. If you use the ones I specify above, the hole size should be 1". You can drill this with a holesaw.

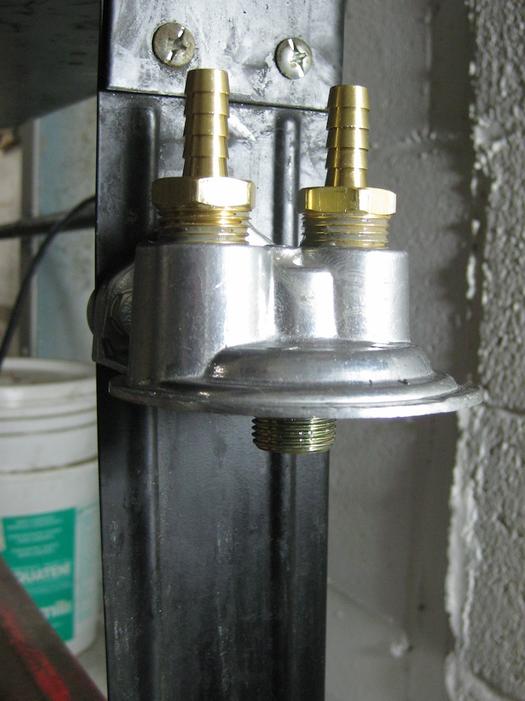

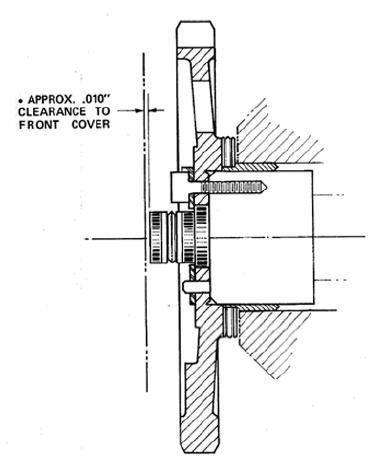

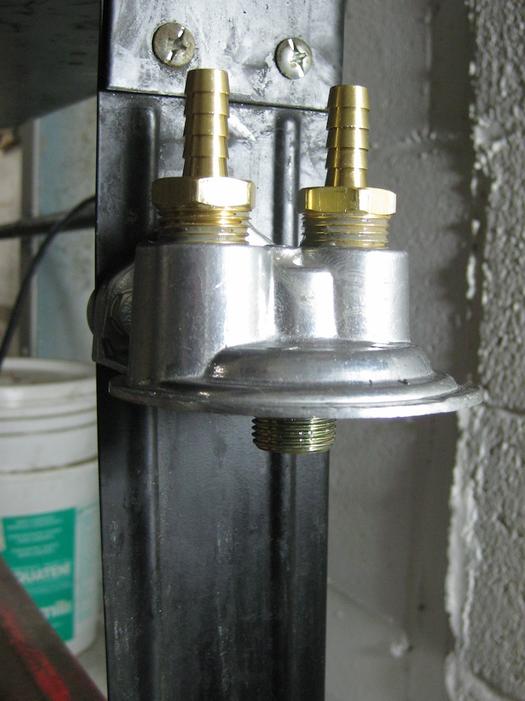

Next, we will mount the filter housing. Place this housing somewhere out of the way. I chose to mount it on the back leg of the parts washer. I chose the perma-cool remote oil filter mount used here because it will fit a two-quart oil filter used on diesel trucks. The inlet and outlet ports are 1/2" NPT. Thread into those two ports 1/2" NPT to 3/8" hose-barb adapter fittings. Use teflon tape or pipe dope on all of the threaded fittings in this project. The filter mount comes with the threaded filter mount separate from the housing. Install this threaded nipple into the filter housing as per the included instructions.

The outlet from the pump on my parts washer is 1/4" NPT. I suspect most of these cheap parts washers are made using the same pump. Check the outlet of your pump to be sure and determine exactly what fitting you need here. From that fitting, adapt to the 3/8" hose with a barbed fitting. For my setup, that meant a 1/4" NPT to 3/8" hose barb. Install that NPT to hose adapter into the outlet of the filter pump using teflon tape or pipe dope. Run a length of thye 3/8" hose from this adapter through one of the holes in the side of the tank and onto another barb to NPT adapter already threaded into the "IN" port on the top of the filter mount.

From the hose barb on the "OUT" port of the filter mount, run a hose back into the parts washer tank through the other grommet. Leaving enough hose to move the parts washer brush around, run that hose to the original brush. Use hose clamps on all of the hose connections.

5. Changing Filters

Depending on how filthy your parts are, you'll periodically need to change filters. If the filter head is mounted below the level of the parts washer tank as mine is, you'll need to clamp off the "IN" hose to stop the siphoning of liquid as you remove the filter. I use vise-grip pliers for this. You could also install a valve - if you find that you are changing filters very frequently - or just mount the filter higher than the tank.

Your parts washer is now ready to use. For around $75 in parts, your parts washer is filtering the cleaning solution like a pro.

http://www.grizzly.com/products/7-Gallo ... stem/H8140