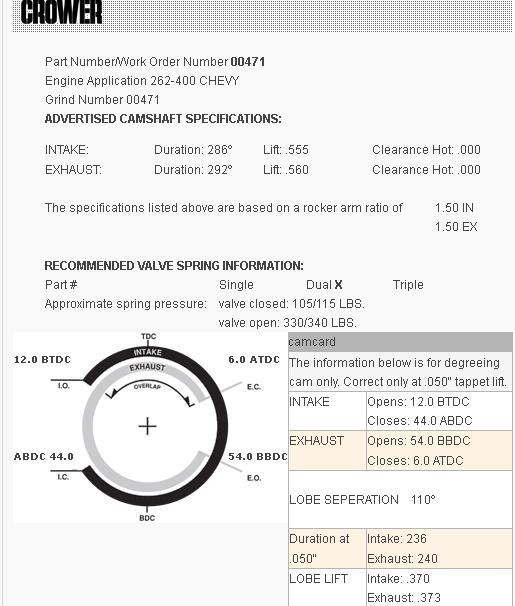

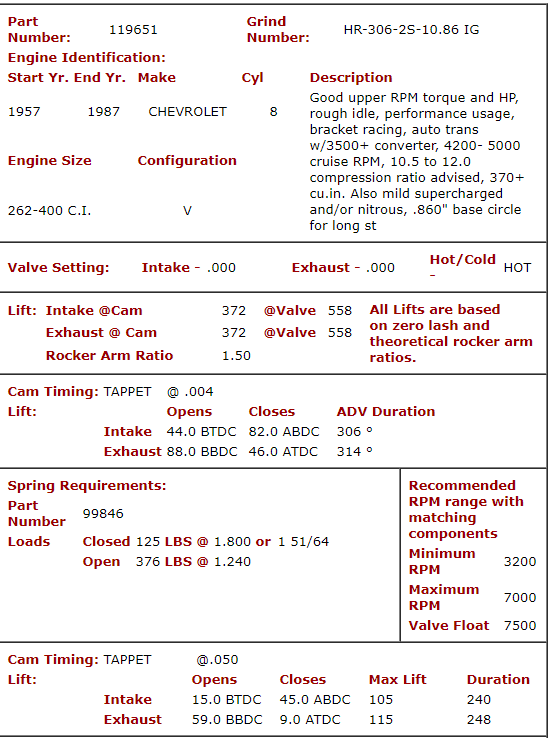

having used that crower cam in several similar , 383-406 sbc engine builds in the past, I can,t wait to see the look on your face once you get everything correctly adjusted and tuned and stomp the throttle from a 30mph rolling start!

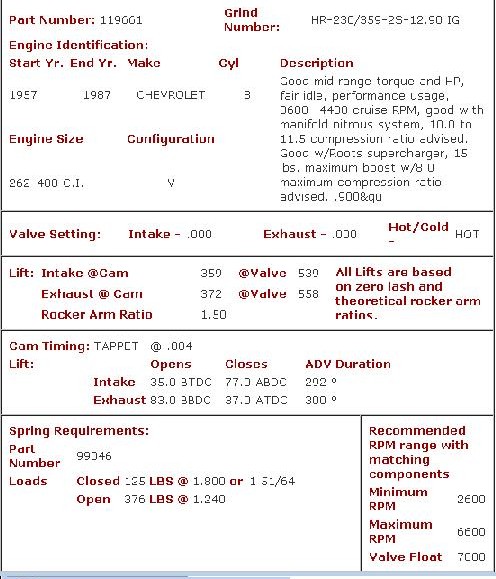

I don,t remember what stall speed converter you said you have , but I was using a 3200 stall in my trans at the time I used it in my corvette , and had ERSON 1.6:1 roller rockers on my 11:1 cpr 383 and it certainly was fun to drive if you were only concerned with performance.

you car should be easily 800lbs-900lbs lighter in weight so it should be really fun.

the only reason I swapped back to the crane 119661 was that the crane cams a bit easier to drive in traffic and cruise with, but the crower has a bit brisker performance.

yes a couple different parts could have been selected that would have easily boosted the power level significantly higher , but it would have resulted in a trade-off that reduced the street drive-ability,in exchange for peak power numbers that were seldom used on the street

RELATED THREAD

viewtopic.php?f=32&t=430

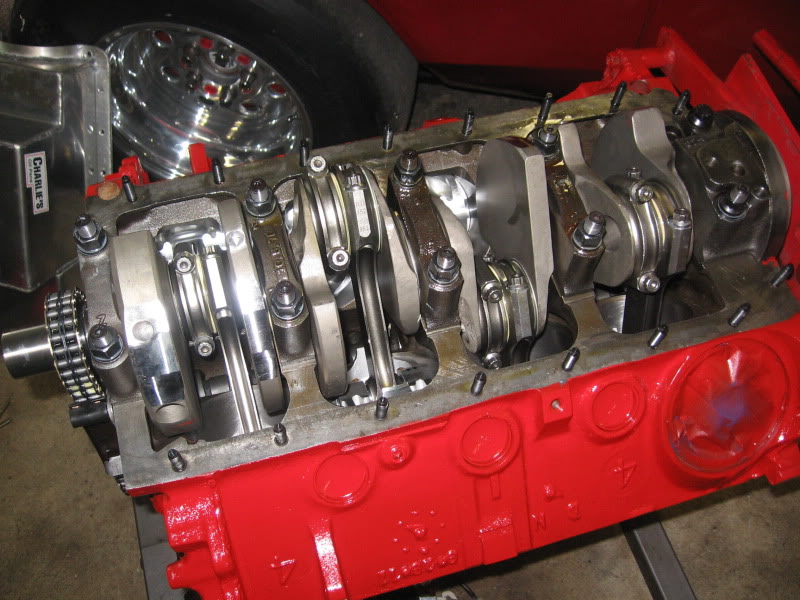

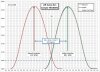

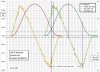

properly tuned, with proper valve train geometry and with the valves properly adjusted,

Ricks engine should rather easily spin about 6300 rpm once the rocker girdles installed,

if the proper valve spring load pressure is still there, so he should be in the 490-530 flywheel hp range.(with the crower 00471 cam)

lets say 400 rear wheel hp and 2400 lbs with him in the T-bucket,car,thus with proper tires and suspension , decent street performance should easily result.

I've built several very similar 383-406 engines,

and even in a 3000 lb vega getting into the very low, to mid 11 second 1/4 mile times is rather easily done.,

provided the tires and suspension, drive train gearing and converter stall, are properly set up.

with Ricks much lighter T-bucket that should not be overly difficult.

keep firmly in mind this combo was not ever intended to be a racing engine, I could have selected several different components to boost potential power noticeably, but it would inevitably , resulted in a marginal or in some combo choices noticeable loss of street drive-ability and some potential loss in durability, which in my opinion is not generally a wise trade off in a street car engine. and you've built an engine that will require higher than pump gas octane fuel and you'll have a combo that won,t cruise at 2500 rpm at 70 mph so it won,t be good for long trips, but the trade -of will result in a quicker and faster 1/4 mile time at the track

http://www.wallaceracing.com/et-hp-mph.php

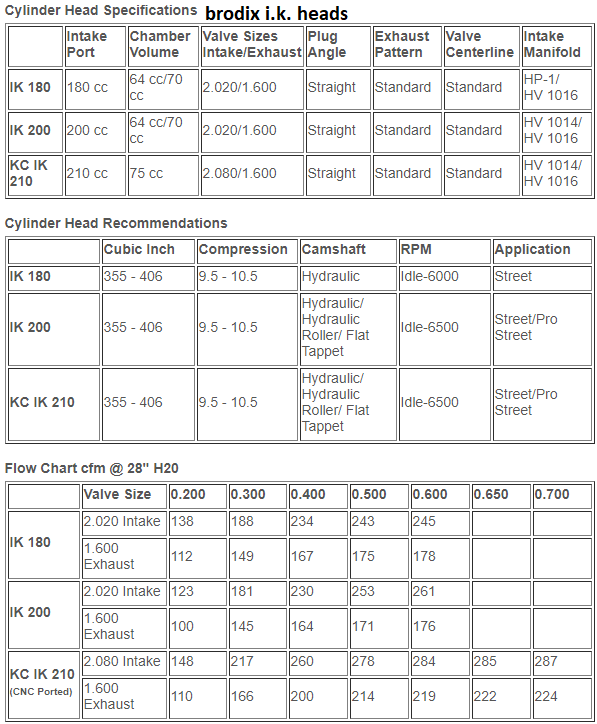

now if you wanted more power,boost the compression to about 11.5:1-12:1 swap to a 3500 stall speed, converter a 4.11:1 rear gear would be a better match, Id suggest you use 1.6:1 roller rockers and a rocker stud girdle ,swap to 210cc brodix Ik heads,

swap to a decent single plane intake, and be well aware the engine will mandate the use of race octane fuel.

http://www.summitracing.com/parts/edl-2892

yes a cam like these linked below

http://www.jegs.com/i/Brodix/158/10...MIp6Gm6vqF2gIVirrACh394QFuEAAYASAAEgJKK_D_BwE

and a cam like this, marginally longer duration crane hydraulic roller,and you would see a very obvious boost in peak power,

probably 75 hp plus, but the cost of the parts jumped up by more than $1200

I've found BRODIX I.K. heads are very good quality, and decent value per dollar,

for a high performance street/strip style engine

https://craftperformanceengines.com...nder-Heads--brodix_cylinder_heads_sbc_ik.html

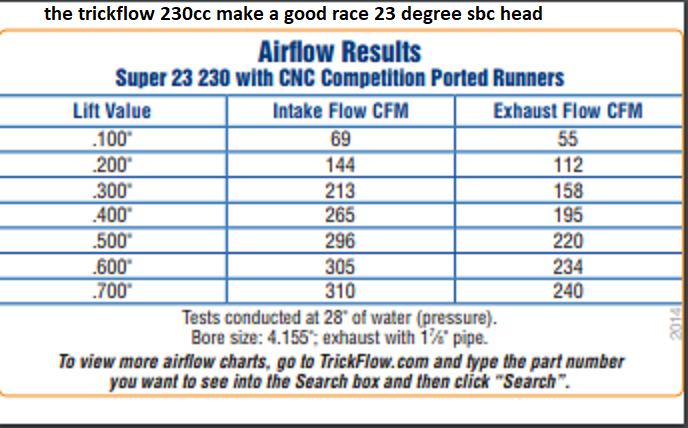

trickflow 230cc makes a good racing sbc head choice

https://www.trickflow.com/parts/tfs-3241t001-c03

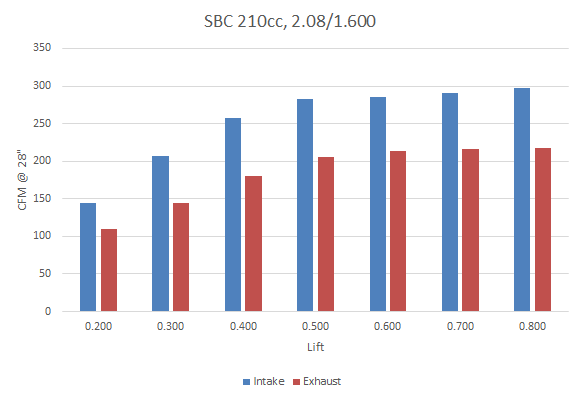

profiler 210cc is a good compromise race and street strip head

https://www.profilerperformance.com/176-sbc-23-degree-heads.html

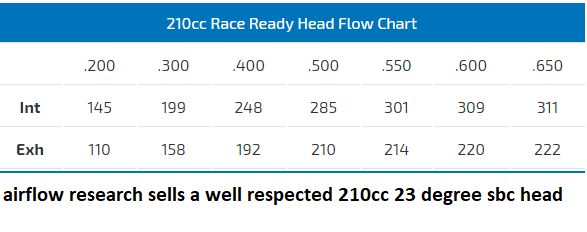

https://www.summitracing.com/parts/afr-1055/overview/make/chevrolet

http://www.airflowresearch.com/210cc-sbc-race-cylinder-head/

related info

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations[/color]

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

https://www.profilerperformance.com/176-sbc-23-degree-heads.html

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-48319

http://garage.grumpysperformance.co...r-flow-heads-the-best-choice.9415/#post-34274

http://garage.grumpysperformance.co...good-street-combo-your-after.5078/#post-14433

http://garage.grumpysperformance.com/index.php?threads/more-port-flow-related-info.322/#post-722