don,t get all physicked out on horsepower numbers, just get it assembled and see how it runs before working about making changes.

personally I think your first few foot to the floor acceleration runs will be a real eye opener, even as it sits now.

theres little doubt this thread shows a well engineered engine combo assembled by Indycars, who has taken the time and effort to research and do things correctly..

Ive build guys engines, or helped guys build engines often enough to know that, the vast majority have never yet seen what a properly configured combo can do , in fact I had one guy a few years ago who was absolutely amazed at the results we got from a fairly mild 496 BBC, when I told him it was a basic 550hp/550 tq build he was disappointed as he thought his previous engine made that much, it didn,t! and he was almost scared to drive his car at first.

viewtopic.php?f=69&t=5123

viewtopic.php?f=69&t=1420

once you see what even 450hp plus/450 ft lbs or more of tq will do to that car. produced by that small block youve built, it will take some adjustment to your driving skills to handle it.

lets say your car weights 2800lbs with you in it and produces 430 rear wheel hp, that already puts you solidly in the high 10 second range adding nitrous could easily get the car into the very low 10 second range possibly even faster, in theory your T-buckets a great deal lighter in weight so it should be amazingly responsive with the engine combo you've built.

Id be rather reluctant to just floor the accelerator in that car until you work up gradually to get a feel for the power levels your controlling, because having built basically similar engines in the past for slightly heavier cars I'm sure you'll be impressed

http://www.wallaceracing.com/et-hp-mph.php

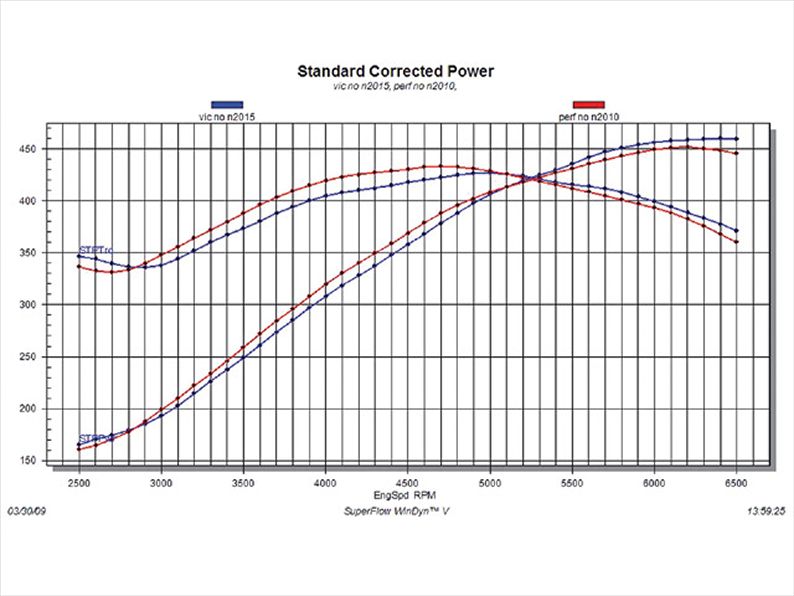

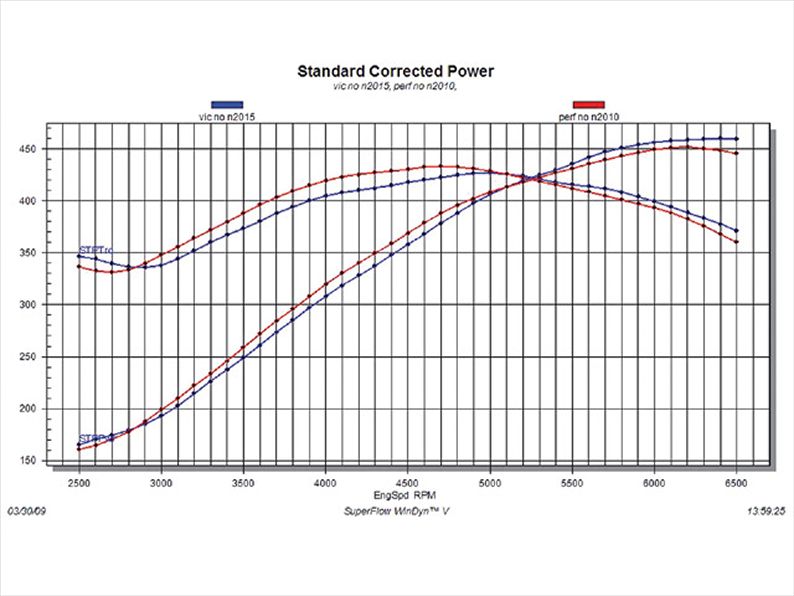

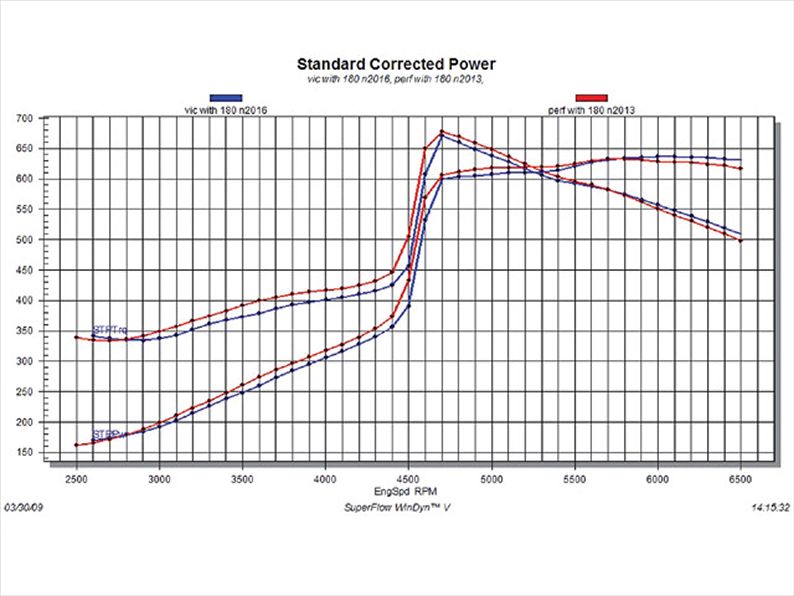

heres a dyno chart on a totally unrelated engine build ,showing the effective difference in the power curve between a rpm air gap dual plane intake and a single plane VIC jr intake, which flows significantly less air than the Holley darton intake, notice the minor loss in low rpm tq and the modest gains in peak power, you could and probably will see a noticeably greater variation if you swap intakes to the Holley/darton single plane design, due to its larger ports and more efficient design.

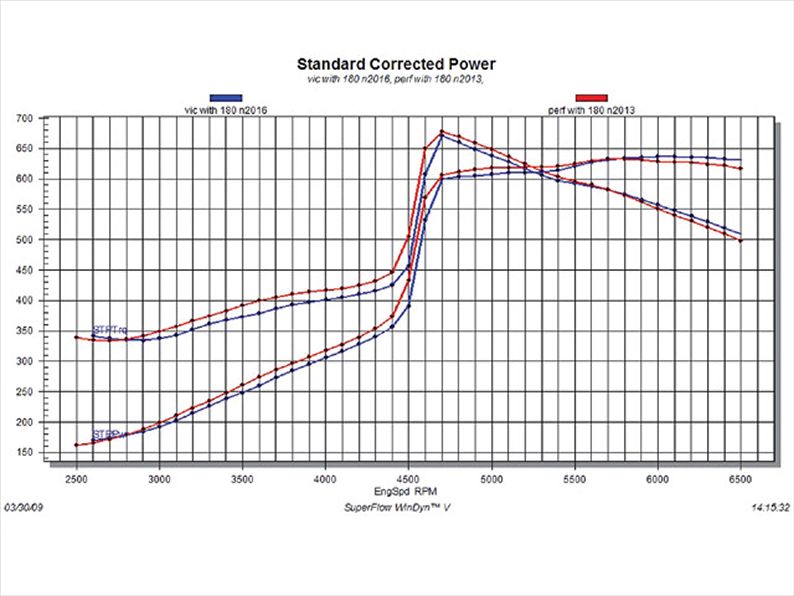

once you master the engines N/A power curve theres always the option of adding NITROUS and your combo will easily pull better numbers that this dyno graph shows

http://static.summitracing.com/global/i ... merrpm.pdf

personally I think your first few foot to the floor acceleration runs will be a real eye opener, even as it sits now.

theres little doubt this thread shows a well engineered engine combo assembled by Indycars, who has taken the time and effort to research and do things correctly..

Ive build guys engines, or helped guys build engines often enough to know that, the vast majority have never yet seen what a properly configured combo can do , in fact I had one guy a few years ago who was absolutely amazed at the results we got from a fairly mild 496 BBC, when I told him it was a basic 550hp/550 tq build he was disappointed as he thought his previous engine made that much, it didn,t! and he was almost scared to drive his car at first.

viewtopic.php?f=69&t=5123

viewtopic.php?f=69&t=1420

once you see what even 450hp plus/450 ft lbs or more of tq will do to that car. produced by that small block youve built, it will take some adjustment to your driving skills to handle it.

lets say your car weights 2800lbs with you in it and produces 430 rear wheel hp, that already puts you solidly in the high 10 second range adding nitrous could easily get the car into the very low 10 second range possibly even faster, in theory your T-buckets a great deal lighter in weight so it should be amazingly responsive with the engine combo you've built.

Id be rather reluctant to just floor the accelerator in that car until you work up gradually to get a feel for the power levels your controlling, because having built basically similar engines in the past for slightly heavier cars I'm sure you'll be impressed

http://www.wallaceracing.com/et-hp-mph.php

heres a dyno chart on a totally unrelated engine build ,showing the effective difference in the power curve between a rpm air gap dual plane intake and a single plane VIC jr intake, which flows significantly less air than the Holley darton intake, notice the minor loss in low rpm tq and the modest gains in peak power, you could and probably will see a noticeably greater variation if you swap intakes to the Holley/darton single plane design, due to its larger ports and more efficient design.

once you master the engines N/A power curve theres always the option of adding NITROUS and your combo will easily pull better numbers that this dyno graph shows

http://static.summitracing.com/global/i ... merrpm.pdf